| viair Compressor compressor

With more customized trucks running the streets with air-adjustable suspension setups than ever before, there is often widespread misinformation given about the need to adequately equip your air-suspended vehicle. Recently, we were able to get one of the fastest movers in the compressor market to stop running long enough to jot down some of the most common questions he receives regarding compressors and their proper use. Sammy Chu, president of Viair Corporation, is kind enough to lay it all out for us in pretty simple terms. If you haven't guessed it yet, Viair makes its own line of 12-volt automotive compressors that outperform just about anything in the market and takes the poundings that we mini-truckers dish out on a regular basis due to our demanding suspension systems. Read on to find all of your answers to your questions by one of the most knowledgeable persons in the world of compressor technology.

For more information, please call Viair Corporation. Its information is listed in the source box of this article as well as in its ad that runs in MT each month. - Editor

How do we choose a compressor that is fast enough for my setup?The bigger the tank, the more airflow is required from the compressor to charge the tank. As a rule of thumb, for each gallon of tank capacity, a minimum of 0.15 cfm at 100 psi is recommended. This means if you have a 5-gallon tank, you need a compressor that puts out about a minimum of 0.75 cfm at 100 psi (0.15 cfm times five equals 0.75 cfm) for the compressor to recharge the 5-gallon tank in a reasonable amount of time.

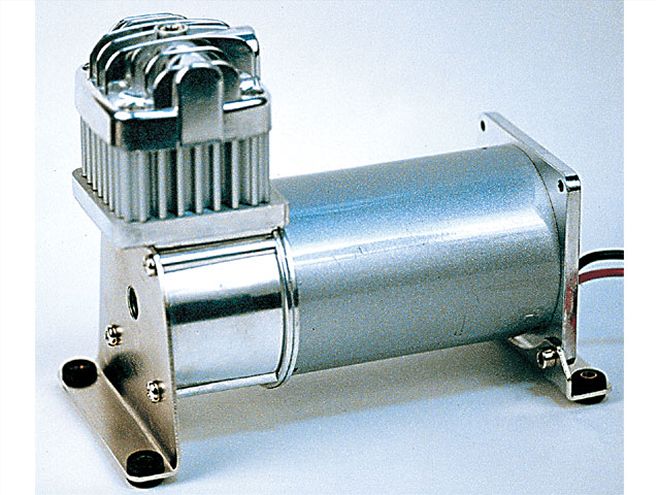

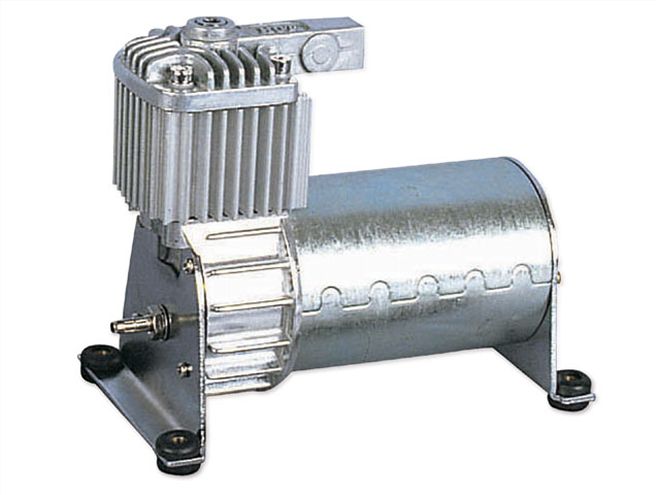

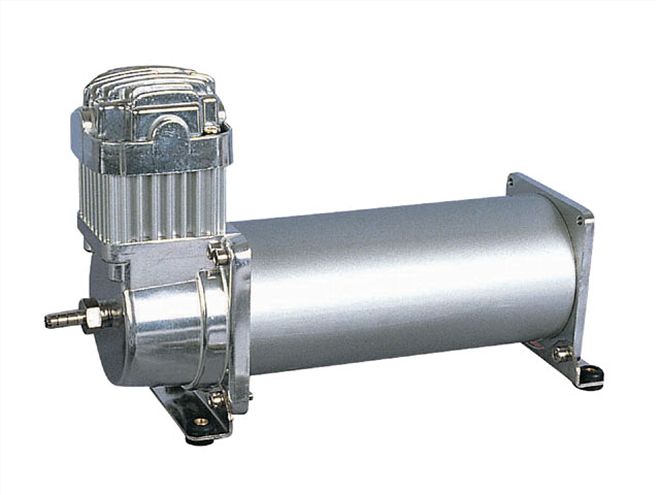

| Model 280

What is cfm?The notation cfm (cubic feet per minute) refers to a volume of air produced by the air compressor at a given pressure or psi (pounds per square inch).

What size air tank should we use? Is one tank enough to suit my needs?In general, tanks that are smaller than 3 gallons are normally used in air-assisted types of suspension setups. For full-function air-suspension systems where air replaces the use of conventional springs, a 5-gallon or higher volume tank is recommended. More than one large tank may work better to suit your needs, though.

You said to look at a compressor's flow rate at 100 psi, but why not look at a rate at 0 psi?Well, cfm at free flow (zero head pressure) is a good reference point, but it does not really tell you the whole story. When you decide to purchase a car or truck, do you ever ask the salesperson how fast the engine will rev while standing still? It is also helpful to get tank fill rates from your compressor supplier.

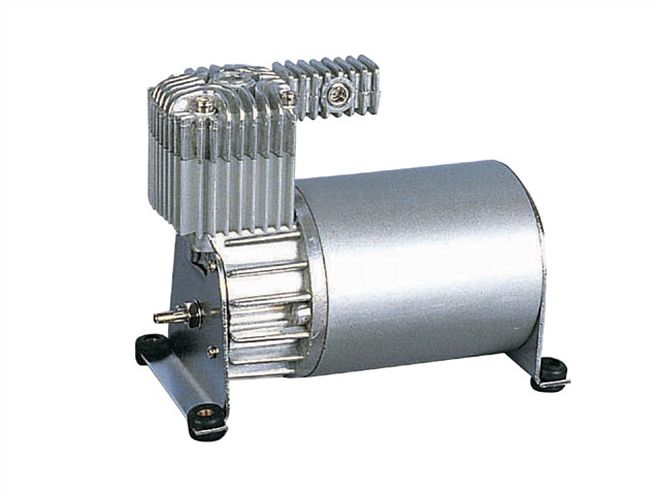

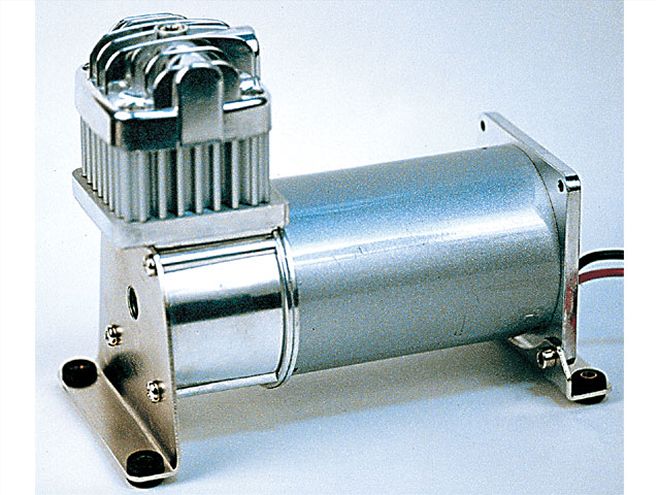

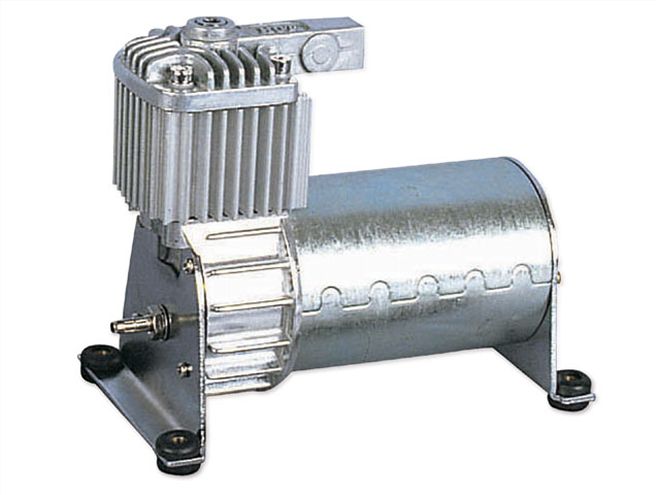

| Model 215

What is duty cycle?A compressor's duty cycle determines the percentage of run time in a full cycle. A full cycle is the compressor run time plus rest time. Duty cycle can be a bit tricky in mobile pneumatics (automotive applications), since we are dealing with a wide range of conditions, applications, and ambient temperatures. Taking into consideration the above, manufacturers generally rate compressor duty cycles at 100 psi at a standard ambient temperature of 72 degrees Fahrenheit. This means a 20-percent duty cycle-rated compressor can run for five minutes (at 100 psi and 72 degrees) and then need to rest for 20 minutes. Five minutes of run time divided by five minutes of run time plus the 20 minutes of rest time equals a 20-percent

duty cycle.

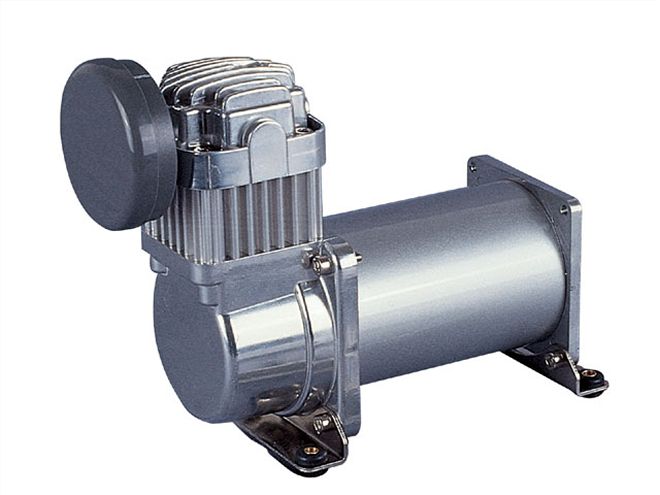

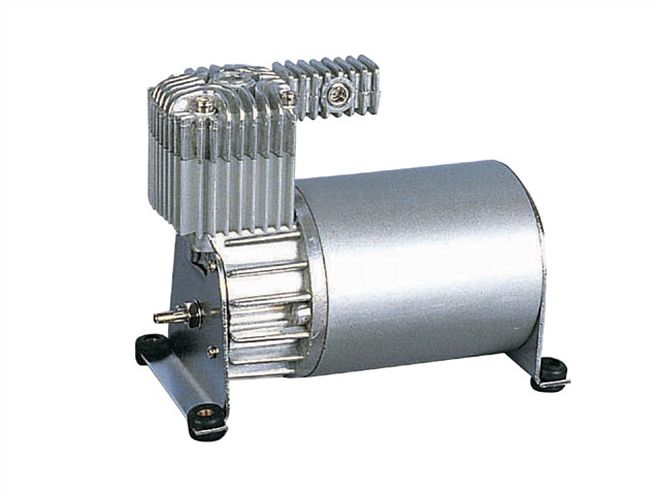

| Model 300

How do we determine how much duty cycle we will need?That's a really good question. This depends how often the compressor will need to come on and how long the compressor will need to run to fill your tank(s) from the cut-in pressure to the compressor cut-off pressure of your pressure switch. For example, let's say that a particular compressor takes two minutes to fill a 5-gallon tank from a cut-in pressure of 110 psi to a cut-off pressure of 145 psi. If we assume that the compressor is required to continuously run the fill cycle five times, then we are looking at 10 minutes of run time, so that is two minutes multiplied by five times. Let's say after you run the compressor continuously for 10 minutes, you would anticipate a rest time of about half an hour, then you are looking at a requirement for a minimum of 25-percent duty cycle-rated compressor. This is figured by taking 10 minutes of run time divided by 10 minutes of run time plus 30 minutes of rest time equaling a 25-percent duty cycle. Remember that duty cycle is rated at 100 psi, so the 25-percent duty cycle requirement that we have calculated based on a cut-in of 110 psi and a cut-off of 145 psi should be considered as the absolute minimum duty cycle requirement for that particular application. It is a good idea to go a bit overkill on your duty-cycle requirement, which means that you should buy a compressor that has a slightly higher duty-cycle rating than what you require.

There are quite a few 100-percent duty-cycle compressors out on the market today. Does a compressor that has a 100-percent duty cycle mean that I can run the compressor all the time, 24/7?This is a often general misconception, and the answer is no, you can't. You have to remember that duty cycle is rated at 100 psi at an ambient temperature of 72 degrees Fahrenheit, but certainly a 100-percent duty cycle compressor can run for much longer periods of time than a 30-percent duty-cycle compressor under similar conditions.

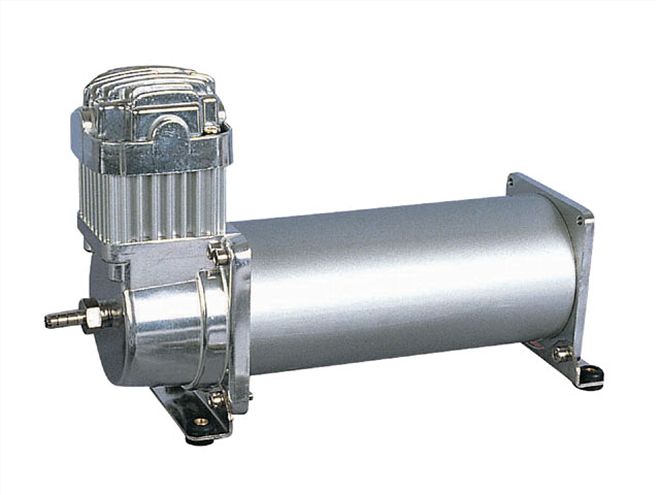

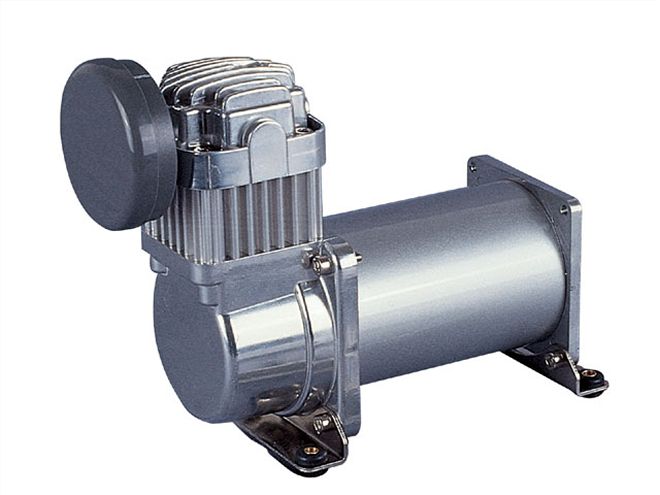

| Model 550

Does it matter where we install the compressor on the vehicle?This depends on several factors, such as the available space, whether or not the compressor is a sealed or vented type, as well as personal preference and aesthetics.

Wait, you just mentioned sealed versus vented-type compressors. What's the difference? Can you elaborate more on those?A compressor that is sealed is moisture- and dust-resistant. This type is obviously a compressor that has no vents. A vented compressor has vents throughout the motor housing and sometimes comes with a cooling fan

in the rear of the motor.

So, a vented type of compressor runs a lot cooler then, right?Exactly! A vented air compressor delivers a higher duty cycle than a sealed compressor, since heat buildup more readily dissipates through the vents.

If a vented air compressor will give me a higher duty cycle, then what's the advantage of even considering a sealed-type compressor?The preference of a sealed-type compressor is because of the fact that in mobile pneumatics, compressors are likely to be exposed to outside elements. High-performance 12-volt compressors are often sealed against moisture and dust to ensure a prolonged life for the compressor.

| Model 400

OK, but when is a vented compressor more suitable for use?Vented compressors can only be installed in an area that is protected from the elements, such as inside a truck's bed when the area is covered, like when you use a tonneau cover on your truck.

That makes a whole lot more sense. So, if we need to install our compressor, say, next to our framerail, we should only consider buying a compressor that is sealed against moisture and dust, right?Yes, and it is a good idea to route an intake filter away from and up to an area where it will draw in cleaner and dryer air if you are able to have a remote intake filter from

the manufacturer.

| Model 450

How can we tell whether the compressor is sealed or non-sealed?Manufacturers normally specify if a compressor is sealed against moisture and dust, and in many cases, you can tell the difference by simply visually inspecting the compressor. If you see vents, cracks, or holes in the motor housing, then it's not a sealed compressor.

So, does that mean if we can't see any vents, the compressor is definitely sealed from moisture and it's dust-resistant?No, not always. Sealing a compressor for moisture- and dust-resistance is a very complicated process. It involves sealing all joints that are not necessarily visible to the

human eye.

| Model 100

Can a compressor that is moisture- and dust-resistant be operated safely underwater?When a compressor manufacturer specifies that a compressor is sealed for moisture- and dust-resistance, it does not mean that the compressor is water- or dust-proof. Operating a compressor while it is submerged in water or sand is one fast way to throw away your money, and it's always obvious to us as to why the compressor fails when we get it back for warranty purposes.

What does the term maximum-rated working pressure mean? Why should we be concerned with a compressor's working pressure?Maximum working pressure is the top-end pressure a compressor can be safely operated to without damaging the compressor or shortening the life of the compressor. Always look at the maximum-rated working pressure of the compressor you have purchased when choosing a pressure switch to use in your suspension system.

| Model 325

What about adjustable pressure switches? Are we able to use them on our suspension system?We generally do not recommend the use of an adjustable pressure switch. This is simply because you may run the risk of setting the cut-out pressure at higher than the maximum-rated working pressure rated for your compressor, or for that matter, you may exceed the maximum-rated working pressure for your air supply tank. This could lead to a catastrophe that no one wants to imagine.

How do we find the maximum-rated working pressure of a compressor?That's simple. Just ask your reputable compressor supplier

for the compressor manufacturer's compressor specifications. It will have that information on hand if it knows the product enough to be selling it.

Is the amp draw of a compressor something that we really need to be concerned with?Yes, the lower the amp draw the compressor requires, the better the compressor is. As a rule of thumb, the maximum amp draw should be no more than 30 amps.

| viair Compressor compressor

With more customized trucks running the streets with air-adjustable suspension setups than ever before, there is often widespread misinformation given about the need to adequately equip your air-suspended vehicle. Recently, we were able to get one of the fastest movers in the compressor market to stop running long enough to jot down some of the most common questions he receives regarding compressors and their proper use. Sammy Chu, president of Viair Corporation, is kind enough to lay it all out for us in pretty simple terms. If you haven't guessed it yet, Viair makes its own line of 12-volt automotive compressors that outperform just about anything in the market and takes the poundings that we mini-truckers dish out on a regular basis due to our demanding suspension systems. Read on to find all of your answers to your questions by one of the most knowledgeable persons in the world of compressor technology.

| viair Compressor compressor

With more customized trucks running the streets with air-adjustable suspension setups than ever before, there is often widespread misinformation given about the need to adequately equip your air-suspended vehicle. Recently, we were able to get one of the fastest movers in the compressor market to stop running long enough to jot down some of the most common questions he receives regarding compressors and their proper use. Sammy Chu, president of Viair Corporation, is kind enough to lay it all out for us in pretty simple terms. If you haven't guessed it yet, Viair makes its own line of 12-volt automotive compressors that outperform just about anything in the market and takes the poundings that we mini-truckers dish out on a regular basis due to our demanding suspension systems. Read on to find all of your answers to your questions by one of the most knowledgeable persons in the world of compressor technology. | Model 280

What is cfm?

| Model 280

What is cfm? | Model 215

What is duty cycle?

| Model 215

What is duty cycle? | Model 300

How do we determine how much duty cycle we will need?

| Model 300

How do we determine how much duty cycle we will need? | Model 550

Does it matter where we install the compressor on the vehicle?

| Model 550

Does it matter where we install the compressor on the vehicle? | Model 400

OK, but when is a vented compressor more suitable for use?

| Model 400

OK, but when is a vented compressor more suitable for use? | Model 450

How can we tell whether the compressor is sealed or non-sealed?

| Model 450

How can we tell whether the compressor is sealed or non-sealed? | Model 100

Can a compressor that is moisture- and dust-resistant be operated safely underwater?

| Model 100

Can a compressor that is moisture- and dust-resistant be operated safely underwater? | Model 325

What about adjustable pressure switches? Are we able to use them on our suspension system?

| Model 325

What about adjustable pressure switches? Are we able to use them on our suspension system?