Some diesel enthusiasts still think of General Motors’ Duramax engine as the new kid on the block. Although, the truth is, its core architecture has now been in production longer than any of the Ford Power Strokes. And fortunately for performance enthusiasts, GM didn’t change injection systems every four years (like the 5.9L Cummins did during its first 10 years), so the aftermarket has been able to build on its knowledge base—not start over from scratch every few model years.

| million Mile Duramax Rebuild 6 6l Duramax Engine

Yet, with all the success these 6.6L, common-rail-injected, aluminum-headed engines have had, many of them are now showing signs of wear after a decade of being in service. We’re now beginning to see way-out-of-warranty LB7 Duramax engines—which were once ahead of their time—becoming victims of time. And many of them are in need of a rebuild.

Duramax Reborn

If you’re part of the GM diesel community and have an older Duramax that just died (or is on its way), pay attention to these steps and your aging diesel will be resurrected as the perfect engine for towing. Thanks to the fact that SoCal Diesel, one of the premiere Duramax diesel engine builders in the country, is located right in our own backyard, Diesel Power is able to bring you an exacting engine build that consists of attaining super-accurate tolerances and obliterating weak links. Though we usually think of SoCal Diesel as a performance shop first—many of the same things that work on race day will also help your truck race to the finish at the end of a long workday.

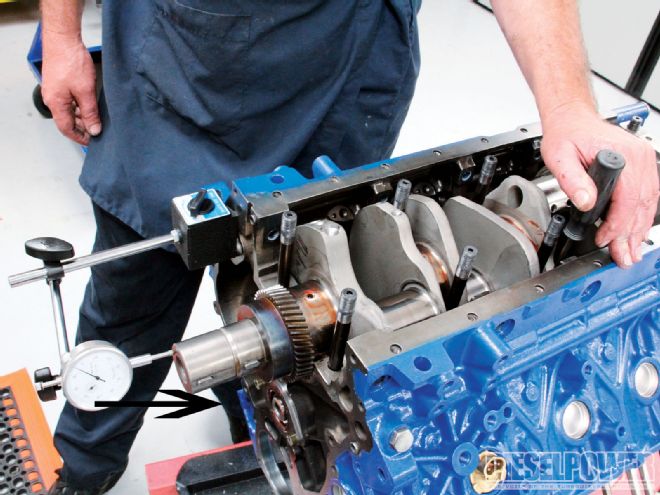

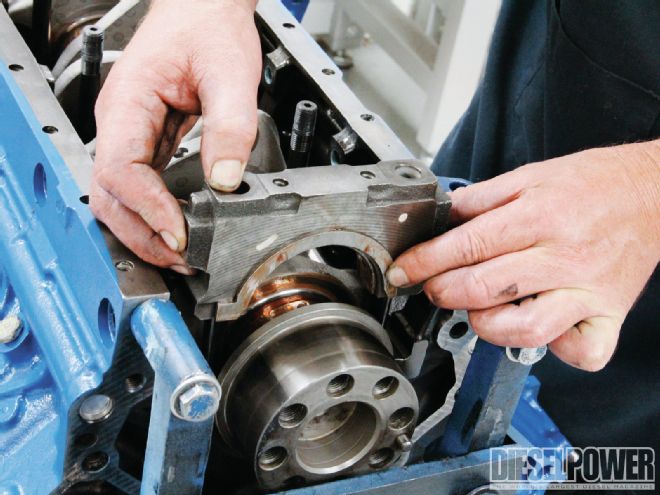

| SoCal Diesel polished each of the Duramax’s crankshaft journals. They were then measured in the same spot relative to each other, and then 90 degrees from that spot to check for roundness. Since crankshaft bearings aren’t perfectly round, the measurements were taken with a dial bore gauge perpendicular to the way the engine sits in the truck. Both the flywheel and harmonic balancer were installed on the crankshaft before being spun on the balancing machine pictured here—because the Duramax engine is externally balanced. Then the bottom end rotating assembly was taken apart and reassembled in the same position when the engine was built. It’s possible to have the crankshaft internally balanced by SoCal Diesel, but we didn’t need that performance option.

The Truck, The Carnage, The Cure The Duramax engine we’re featuring in these pages came out of an ’03 Chevy Silverado 3500 dualie with a ZF6 six-speed manual transmission, four-wheel drive, and 130,000 miles on the odometer when it blew up towing a load of steel over the Rockies. About eight years before that fatal towing trip, the truck was fitted with a programmer, 4-inch exhaust, and an exhaust brake.

The truck spent most of its life towing off-road vehicles around the West, and as the miles added up, the truck showed the normal signs of wear and tear. The part that wasn’t normal, however, was that the ZF6 six-speed’s case broke in half at 47,000 miles, the injectors began leaking, causing one of the pistons to split. The cause of our Duramax’s death was determined to be a worn injector that was left in service too long. The leaking injector dripped fuel into the cylinder, causing that piston to be super heated, and ultimately fail when it seized in the cylinder bore. This is a very common (and preventable) problem that is made worse when the engine idles a lot, as it tends to in cold climates. Extended idling times with a bad injector is like eating fast food every day with a heart condition.

Block Preparation

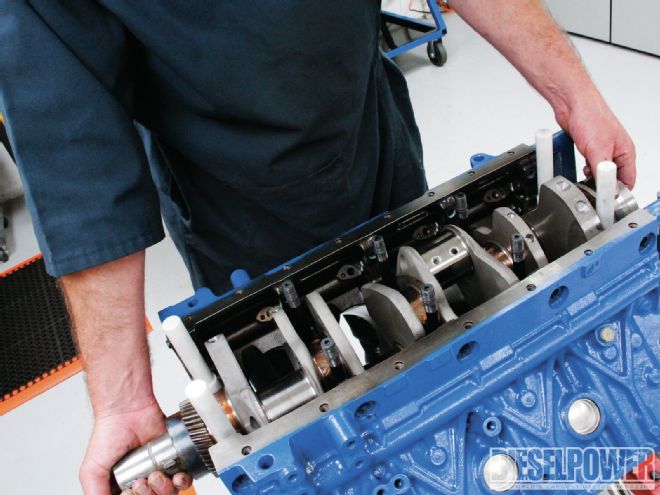

After our Duramax got an autopsy and was disassembled, SoCal Diesel’s Guy Tripp discovered the main engine parts (the block, crankshaft, connecting rods, and heads) were all OK. The LB7 was then taken to SoCal’s state-of-the-art machine shop, where the block got its steel freeze plugs removed. Then it was baked and shot-peened. Once cleaned, the block was line-honed and then decked and bored 0.020-over on an RMC v30 block CNC machine to ensure the cylinders were square with the block.

But the real magic came with the finish honing of the cylinder walls. Using a Sunnen SV-10 hone and an eight-stone diamond hone (equipment typically used only for NHRA Pro Stock drag racing engines), the Duramax was blueprinted to specifications that Dmax LTD in Ohio would be envious of. Finally, the cam bearings, oil plugs, and freeze plugs were reinstalled, and the block was shot with SoCal Diesel’s traditional blue paint.

’01 to ’04 6.6L Duramax LB7 Torque Specifications

A/C Compressor Bolt: 37 ft-lb

A/C Compressor and Power Steering Pump Bracket Bolt: 34 ft-lb

Camshaft Gear Bolt: 173 ft-lb

Camshaft Position Sensor Bolt: 89 in-lb

Camshaft Position Sensor Exciter Ring Bolt: 80 in-lb

Camshaft Thrust Plate Bolt: 16 ft-lb

Charged Air Cooler Bolt: 15 ft-lb

Charged Air Cooler Clamp: 71 in-lb

Connecting Rod Cap Bolt (Angular Tightening Method): 1st Step 47 ft-lb; 2nd Step 30 degrees; 3rd Step 30 degrees

Coolant Pipe to Water Pump: 18 ft-lb

Cooling Fan Pulley: 30 ft-lb

Crankshaft Balancer Bolt: 1st Step 74 ft-lb; 2nd Step 105 degrees

Crankshaft Bearing Cap Bolt (Angular Tightening Method): 1st Step 72 ft-lb; 2nd Step 97 ft-lb; 3rd Step 60 degrees

Crankshaft Bearing Cap (Side): 52 ft-lb

Crankshaft Position Sensor Bolt: 89 in-lb

Crankshaft Position Sensor Spacer Bolt: 89 in-lb

Crossmember Bolt: 74 ft-lb

Cylinder Head M12 Bolts (Angular Tightening Method): 1st Step 37 ft-lb; 2nd Step 59 ft-lb; 3rd Step 60 degrees; 4th Step 60 degrees

Cylinder Head M8 Bolts: 18 ft-lb

Drive Belt Tensioner Pulley Bolt: 30 ft-lb

Engine Block Coolant Plug: 13 ft-lb

Engine Mount (Through Bolt to Frame): 55 ft-lb

Engine Mount (Bolt to Block): 43 ft-lb

Engine Mount (Frame Bolt): 48 ft-lb

Engine Shield Bolts: 15 ft-lb

Exhaust Heat Shield Nut: 80 in-lb

Exhaust Manifold Bolt or Nut: 28 ft-lb

Exhaust Manifold Heat Shield Bolts: 71 in-lb

Exhaust Outlet Clamp: 11 ft-lb

Exhaust Outlet Heat Shield Bolts: 71 in-lb

Exhaust Outlet Pipe Bolt: 39 ft-lb

Exhaust Pipe Bolt: 39 ft-lb

Exhaust Pipe Bracket Bolt: 25 ft-lb

Exhaust Pipe Clamp: 30 ft-lb

Exhaust Pipe Heat Shield Bolts: 71 in-lb

Fan Pulley Bracket Bolt: 34 ft-lb

Flywheel Bolt (Angular Tightening Method): 1st Step 58 ft-lb; 2nd Step 60 degrees; 3rd step 60 degrees

Flywheel Housing to Block Bolt: 60 ft-lb

Flywheel Housing to Upper Oil Pan Bolt: 37 ft-lb

Front Engine Cover Bolt: 15 ft-lb

Fuel Block Bolt: 18 ft-lb

Fuel Filter Bracket Bolt: 15 ft-lb

Fuel Injection Control Module Bolt: 15 ft-lb

Fuel Injection Control Module Bracket Bolt: 15 ft-lb

Fuel Injection Control Module Connector Bolt: 89 in-lb

Fuel Injection Control Module Connector Bracket Bolt: 15 ft-lb

Fuel Injection Control Module Cooler Eye Bolt: 20 ft-lb

Fuel Injection Pipe Nut: 30 ft-lb

Fuel Inlet Pipe Bracket Bolt: 15 ft-lb

Fuel Pipes Bracket Bolt: 18 ft-lb

Fuel Rail Assembly Bolt: 18 ft-lb

Fuel Rail Connector: 33 ft-lb

Fuel Return Pipe Eye Bolt (Cylinder Head and Injector Side): 12 ft-lb

Fuel Return Pipe Sleeve Nut: 30 ft-lb

Fuel Return Sleeve Unit: 30 ft-lb

Fuel Injection Pump Assembly to Cylinder Block Bolt: 15 ft-lb

Fuel Injection Pump to Bracket Bolt: 15 ft-lb

Fuel Injection Pump Drive Gear Nut: 52 ft-lb

Fuel Line Bracket Nut: 15 ft-lb

Fuel Temperature Sensor Eye Bolt: 11 ft-lb

Glow Plug: 13 ft-lb

Glow Plug Connector Nut: 18 in-lb

Glow Plug Power Feed Nut: 11 ft-lb

Glow Plug Relay Assembly Bolt: 18 ft-lb

Heater Outlet Pipe/Nose Bolt: 18 ft-lb

Heater Outlet Pipe/Nose Nut: 80 in-lb

Heater Pipe Bolt: 15 ft-lb

Idle Pulley Bolt: 27 ft-lb

Injector Bracket Bolt: 37 ft-lb

Injector Harness Bracket Bolt: 80 in-lb

Injector Terminal Nut: 18 in-lb

Injector Pipe Lock Plate Screws: 35 in-lb

Intake Air Heater: 37 ft-lb

Intake Air Heater Terminal Nut: 35 in-lb

Intake Manifold Bolts and Nuts: 15 ft-lb

Intake Manifold Tube Bolts and Nuts: 80 in-lb

Oil Cooler Adapter Bolts: 15 ft-lb

Oil Cooler Adapter Nuts: 18 ft-lb

Oil Cooler Assembly Bolts: 18 ft-lb

Oil Cooler Adapter Stud: 89 in-lb

Oil Drain Plug: 62 ft-lb

Oil Fill Tube Bolt: 15 ft-lb

Oil Level Indicator Tube Bolt: 15 ft-lb

Oil Level Sensor Bolt: 89 in-lb

Oil Pan Bolts and Nuts (Lower): 89 in-lb

Oil Pan Bolts (Upper): 15 ft-lb

Oil Pan Skid Plate Bolt: 15 ft-lb

Oil Pressure Sensor Unit: 22 ft-lb

Oil Pressure Relief Valve: 29 ft-lb

Oil Pump Bolt: 15 ft-lb

Oil Pump Driven Gear Nut: 74 ft-lb

Oil Pump Gear Cover Bolt: 15 ft-lb

Oil Strainer Bolts and Nuts: 18 ft-lb

Piston Cooling Nozzle Eye Bolt: 15 ft-lb

Power Steering Pump Bracket Bolt: 37 ft-lb

Power Steering Pump Bolt: 37 ft-lb

Power Steering Pump Bracket Bolt: 34 ft-lb

Rocker Arm Shaft Bracket Bolt: 30 ft-lb

Starter Motor Bolt: 58 ft-lb

Transmission Fill Tube Nut: 13 ft-lb

Thermostat Cover Bolt: 15 ft-lb

Torque Converter Bolt: 44 ft-lb

Transmission Oil Cooler Clip Nut: 80 in-lb

Turbocharger Bolt: 80 ft-lb

Turbocharger Boost Sensor Bolt: 89 in-lb

Turbocharger Coolant Outlet Pipe Bracket Bolts: 15 ft-lb

Turbocharger Oil Return Pipe Stud: 89 in-lb

Turbocharger Oil Supply Hose Eye Bolt: 25 ft-lb

Turbocharger Oil Return Pipe Bolts and Nuts: 15 ft-lb

Turbocharger Thermostatic Coolant Valve: 44 ft-lb

Upper Oil Pan to Flywheel Housing Screws: 15 ft-lb

Vacuum Pump Nuts (California Emissions): 16 ft-lb

Valve Adjusting Screw Nut: 16 ft-lb

Valve Lifter Hold-down Bracket Bolt: 97 in-lb

Valve Rocker Arm Cover Bolts (Lower): 89 in-lb

Valve Rocker Arm Cover Bolts (Upper): 71 in-lb (two times)

Water Outlet Bolts: 18 ft-lb

Water Pump Bolts: 15 ft-lb

(Courtesy of SoCalDiesel.com)