We receive emails like this all the time: “My Name is Mark Vanadia, and I am a 23-year-old from Northern New Jersey who reads 8-Lug HD Truck magazine as often as I possibly can. I currently own an ’06 Ford F-350 with the 6.0L diesel engine. I purchased the truck new in December 2005 and took pride to build it up with the following: a 10-inch Donahoe Racing lift, a set of 24-inch Fuel Off-Road Hostage wheels, 38-inch Kumho Mud Terrain tires, a full Banks Big Hoss kit, and some other modifications. The reason I’m emailing you is because (like so many people) I have blown my head gaskets in the truck, and I’m planning to do a complete rebuild of the upper half of the motor, which will include EGR delete, a PowerMax turbo, larger injectors, oil cooler rebuild kit, coolant filter kit, new tuner, and more.

| 01. This is Mark Vanadia’s ’06 F-350 Lariat 6.0L Power Stroke extended-cab shortbed pickup truck as it sat before the rebuild. The truck has a 10-inch Donahoe Racing suspension lift with Pro Comp traction bars, a Donahoe dual steering stabilizer setup, Kumho 38x14.00 Road Venture mud terrains, and 24x11 black Fuel Hostage wheels. As it sits in this picture, the truck also has blown head gaskets.

“What makes me unique is I have a very good friend who has the same situation with his ’05 6.0L that is lifted and customized in a way similar to mine. We are planning to do the rebuilds ourselves in his garage on the weekends. I was hoping this might be of interest to readers who are uncertain if they can complete a project like this. I wanted to see if this is something worthy of coverage in your magazine. We are planning on doing the job right, have done our research, and are just two friends who like to work on our trucks. I will be willing to do whatever is necessary to have this story in your magazine. We are currently purchasing parts from the best suppliers who are willing to work with us (so far every manufacturer I have contacted is willing to), and we’re looking to start the cab-off rebuild within the next two weeks. Thank you very much for your time.”

We promised Mark if he could take good photos, this could turn into a very nice article. He swore he would make sure the engine build was nicely photographed—so the deal was done. And here you have it. We’ll let Mark continue to tell the story. “This truck is my pride and joy. I have babied it from day one of purchasing it new. After blowing the head gaskets, I realized there were many options for getting the truck fixed, but it only seemed right that I took on the adventure myself with the help of three good friends. We did the work in one of their garages. In the middle of the process, we decided this truck would have to make it out to the All-Truck Nationals in Carlisle, Pennsylvania, the first weekend in August. The idea was to simply repair the truck and install slightly larger injectors (some 190s) and a slightly larger turbo (Garrett PowerMax)—and get it running with about 450 to 500 hp. As I started this build, the 450-to-500-rwhp mark quickly turned into a quest for 600-plus rwhp.”

| 02. Here is the Ford after we added a set of stock wheels on 33s, which made it easier to maneuver the truck as well as give less concern for scratching the 24s.

This project was such a success that some of the guys have started their own company, specializing in work like this. Big Time Kustomz (973-296-8503) is a new shop that formed from friends who worked on the project and is an extension of their enjoyment of it. You can see a complete log of this build on www.bigtimekustomz.com. The following chronicles Mark’s adventure.

03. We started by draining all the fluids and removing the grille, lights, header panel, wiring, front bumper, hood, wiper cowl, and other parts to start tearing down the truck. We also removed the bed to gain access to the frame for paint. After removing the A/C condenser, transcooler, intercooler, and radiator, we were staring at the fan, which was the only thing that separated us from the front of the motor. Our original concept was to leave the motor in the truck and raise the cab enough to get to the motor. That idea quickly changed.

| total Rebuild 2006 Ford F350 drain All Fluids And Remove Grille

04. Since we basically had the entire front end of the truck torn down, it only seemed right to just unbolt the motor mounts and pull the engine rather than try to lift the cab. Not to mention, our goal had changed from the slight power upgrade to a daily driver with a 600hp goal. Because of that, the transmission was getting a complete Stage 3 rebuild, filled with Suncoast transmission parts, as well as a Suncoast torque converter. So once we pulled the transmission out, the motor came out with ease.

| total Rebuild 2006 Ford F350 unbolt Motor Mounts

05. Here is a shot of the motor pulled out of the truck. As it sits here, it is a complete rolling chassis. We did have to unbolt the front four cab bolts in order to raise the cab off the frame slightly so the oil pan would clear the frame (we did this because we were restricted with the height of the engine hoist). While pulling the motor, we were careful to make sure nothing got hung up anywhere, as well as being sure all the wiring harnesses were disconnected and cleared out of the way.

| total Rebuild 2006 Ford F350 motor Removed From Truck

Complete List of Upgrades:

- Steel cowl hood

- ’10 tailgate with step and camera

- ’10 mirrors

- Recon LED cab lights, third brake light, dome light, mirror lights

- Bestop PowerBoards

- Red LED conversion

- Customs gauge faces from Black Cat Customs

- Pioneer DVD/navigation unit

- ARP head studs

- Injectors from Warren Diesel

- New factory head gaskets

- Oil cooler rebuild

- EGR delete

- New bellows in the up-pipes

- 5-inch turbo-back stainless steel MBRP exhaust

- AirDog II fuel system

- Highline South Motorsports regulated-return fuel system

- Custom tunes written from Eric at Innovative Diesel and Matt at Gearhead Automotive

- Coolant filter kit

- Stage III transmission rebuild from Suncoast (rebuilt by us)

- Suncoast torque converter

- S&B cold-air intake

- Snow Performance methanol injection kit

- Edge CTS monitor on custom mount

- GlowShift gauges

- 10-inch Donahoe Racing lift installed by Krazy House Customs

- 24-inch Fuel Hostage wheels

- 38-inch Kumho Road Venture mud terrain tires

- Pro Comp traction bars

- Donahoe Racing dual steering stabilizer

| 06. Once the motor was pulled out, we set it down on blocks, making sure it was steady and solid to start tearing the top end down.

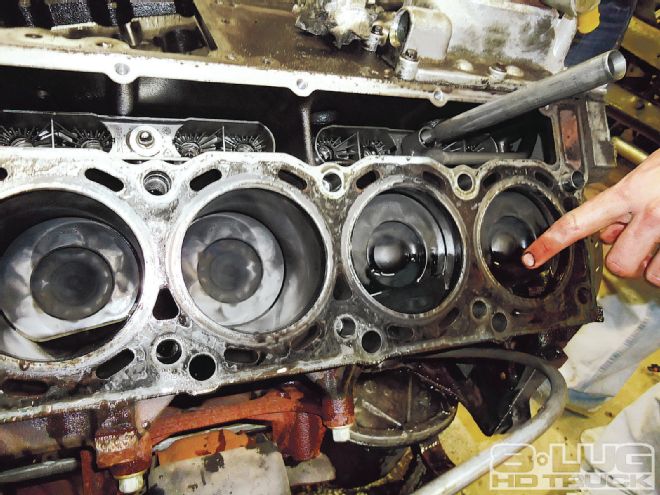

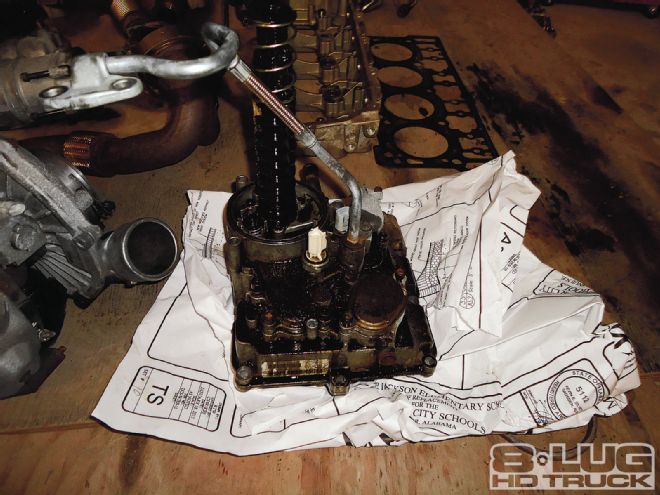

13. Once we had the injectors back from Warren Diesel and the heads back from the machine shop, we started putting the motor back together. With the cylinders cleaned out and the block prepped, the head studs went in, the factory gaskets were put in place, and the fresh heads were slid on. After the heads, the injectors went in, along with the pushrods and other internals. Then the oil rails went in with the other top-end parts. Once the internals were set and torqued properly, the covers went back on along with the intake manifold (now with the EGR delete installed) as well as the freshly rebuilt oil cooler, new Garrett PowerMax SSX turbo, and the regulated-return fuel system from Highline South. We also upgraded the spring inside the factory fuel regulator and installed some banjo bolts from the 6.4L Power Stroke. Once mostly everything was reinstalled on the motor, we put the FICM back in place, installed the head shields, and connected the wire harnesses. Once the exhaust manifolds were reinstalled (with gaskets), we went to work on the up-pipes.

| 06. Once the motor was pulled out, we set it down on blocks, making sure it was steady and solid to start tearing the top end down.

13. Once we had the injectors back from Warren Diesel and the heads back from the machine shop, we started putting the motor back together. With the cylinders cleaned out and the block prepped, the head studs went in, the factory gaskets were put in place, and the fresh heads were slid on. After the heads, the injectors went in, along with the pushrods and other internals. Then the oil rails went in with the other top-end parts. Once the internals were set and torqued properly, the covers went back on along with the intake manifold (now with the EGR delete installed) as well as the freshly rebuilt oil cooler, new Garrett PowerMax SSX turbo, and the regulated-return fuel system from Highline South. We also upgraded the spring inside the factory fuel regulator and installed some banjo bolts from the 6.4L Power Stroke. Once mostly everything was reinstalled on the motor, we put the FICM back in place, installed the head shields, and connected the wire harnesses. Once the exhaust manifolds were reinstalled (with gaskets), we went to work on the up-pipes.

| total Rebuild 2006 Ford F350 being Putting Motor Back Together

20. With only a few hours of daylight left, we had to move quick to get the new Suncoast torque converter installed, trans bolted up to the motor, transfer case installed, and the motor dropped into the frame. All that was necessary so we could put the cab back on the truck (under the tarp in the upper right corner of the picture).

| total Rebuild 2006 Ford F350 being Putting Motor Back Together

20. With only a few hours of daylight left, we had to move quick to get the new Suncoast torque converter installed, trans bolted up to the motor, transfer case installed, and the motor dropped into the frame. All that was necessary so we could put the cab back on the truck (under the tarp in the upper right corner of the picture).

| total Rebuild 2006 Ford F350 install Suncoast Torque Converter

24. We had the cab back down on the frame, and after hooking up the steering, we bolted the cab back to the frame and double-checked to make sure everything was set properly. We loaded the truck onto the flatbed from Tony’s Towing and hauled the Ford back to our buddy’s house, where we planned to get the truck running in the next five days.

| total Rebuild 2006 Ford F350 install Suncoast Torque Converter

24. We had the cab back down on the frame, and after hooking up the steering, we bolted the cab back to the frame and double-checked to make sure everything was set properly. We loaded the truck onto the flatbed from Tony’s Towing and hauled the Ford back to our buddy’s house, where we planned to get the truck running in the next five days.

| total Rebuild 2006 Ford F350 load Truck Onto Tow Truck

25. Once we got the truck back in the garage, we started hooking up all the wire harnesses, grounds, coolers, radiator, and batteries. We installed the new AirDog II fuel system, and after two solid nights of working we were ready to get the motor to crank over for the first time. After priming the system (and multiple cycles with the battery…and short, cranking bursts) the truck fired up. We let it run for a few minutes, and then shut her down. The four of us could not be any happier. We cleaned up for the night and would be ready to start fresh after work the next day.

| total Rebuild 2006 Ford F350 load Truck Onto Tow Truck

25. Once we got the truck back in the garage, we started hooking up all the wire harnesses, grounds, coolers, radiator, and batteries. We installed the new AirDog II fuel system, and after two solid nights of working we were ready to get the motor to crank over for the first time. After priming the system (and multiple cycles with the battery…and short, cranking bursts) the truck fired up. We let it run for a few minutes, and then shut her down. The four of us could not be any happier. We cleaned up for the night and would be ready to start fresh after work the next day.

| total Rebuild 2006 Ford F350 install Airdog 2 Fuel System

| total Rebuild 2006 Ford F350 install Airdog 2 Fuel System