Triple Turbo Setup - Reaping the Benefits

Trent Nell paid his dues with 10 years as an ASE-certified mechanic. He also paid his dues as a consumer of performance diesel products by racing a 9-second Duramax. Combining the two, Trent told us, “became a 24-hour job.”

| This is pretty much everything that comes with the triple-turbo kit from Extreme Prejudice Racing.

That’s when he decided to make the jump to performance diesel work full-time with his own shop, Extreme Prejudice Racing. The hours have hardly decreased. Trent works mainly by himself, calling in help when he really can’t get everything done or when someone else’s special skills will make the parts better. “When customers call about a product,” Trent said proudly, “they get the guy who designed it, built it, and installed it.”

We can attest to that fact. We stopped by Extreme Prejudice Racing, located in the shadows of Salt Lake City in sleepy little Midvale, Utah, and were treated to seeing a triple-turbo kit that was under development.

Why a triple-turbo setup? Trent explains that (compared to a standard compound-turbo setup) the triples use two smaller turbos that spool up quicker to feed the factory high-pressure turbo, which results in them coming on twice as fast. “It’s very efficient using expelled heat to drive the turbo,” Trent added. So the number one reason for triple turbos is spoolability. The system is a bit more complicated and costs a bit more, but the results (not to mention the wow factor) can be worth it.

One possible annoyance is that the second battery must be moved to make room for the triple-turbo kit. Trent pointed out that GM makes a bracket for the company’s military applications that mounts the battery under the door.

| Here’s what it all looks like when it is assembled on the engine. It’s expensive, but speed costs money.

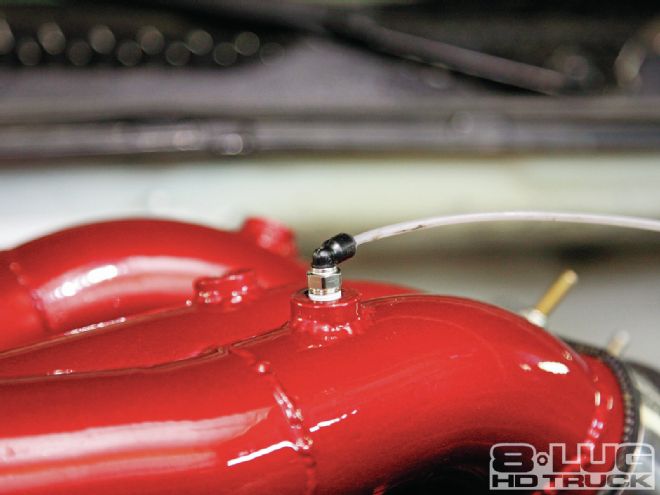

The kit was almost completely done when we arrived at Extreme Prejudice Racing—but not quite. What you see in these photos is a prototype kit. Trent wanted to point out that the tubes in these photos are merely MIG-welded and Trent is an amazingly talented TIG-welder, so he wants everyone to know the final kits will be even better looking. Of course, even though it’s just a prototype, Trent still went to the trouble of powdercoating everything so it would look good. Kevin Langford and the crew at Powder Extreme Coatings (www.powderextremecoatings.com) worked all weekend to get the job done so Trent’s kit would look good for the photos. There’s no question why both these companies have the word “Extreme” in their names. We should also mention that the turbos came from the extreme people at Gillett Diesel in Bluffdale, Utah. Trent swears by them.

For the record, we’re not going to try and bluff you into thinking we took photos step by step while the kit was installed and then drove it over to the dyno to see what it would do. We photographed some of the parts as Trent was checking fitment—the kit was not completed while we were there. But about a week later it was, and Trent put the truck on the dyno and ran it hard, really hard—like, 1,117.5 lb-ft of torque and 545.7 hp hard. Take a look at the dyno sheet included with this story. The power comes on early and stays around all day. You can contact Trent through email at Trentnell@gmail.com, call him at (801) 599-3922, or check out his website at www.extremeprejudiceracing.com.