In part one of Torque Tech, we subjected our 5.3L test engine to a few much-needed bolt-on performance parts. Adding a set of GenX 205 heads and matching cam from Trick Flow Specialties along with a FAST LSX intake manifold, the 5.3L produced 483 HP and 438 lb-ft of torque. Happy as we were with the current output of the 5.3L, we couldn't help but want even more torque production lower in the rev range. Ever the greedy enthusiast, we wanted the extra torque to come without sacrificing the impressive peak power numbers-enter increased displacement.

| 5 3L 383 Stroker Engine Build dyno Tests

Here is some pretty simple performance math. If you are looking to produce a given amount of power, it is always easier to reach that power goal with a larger engine. In this case, bigger really is better, as it is easier to make 500 HP with a 400-inch engine than one displacing just 300 cubic inches. In our case, we weren't looking for big-time peak horsepower power gains as much as tremendous torque. We liked the 483 HP, but wanted more than 438 lb-ft currently offered by the modified 5.3L combination.

One upgrade that promised enhanced torque production without sacrificing any peak power was increased displacement. A little math helps here to understand what might be possible with a hike in displacement. Using the torque output of the 5.3L, we see that 5.3L (324ci) LS combination offered 1.35 lb-ft per cubic inch (438 lb-ft/324ci). If we apply this specific torque output formula to our new stroker combination of 383 cubic inches (1.35 x 383ci), the result might be an impressive 518 lb-ft of torque. That is some serious torque potential, and only the dyno will let us know if we are able to achieve that, but in addition to that peak number, the 383ci stroker will offer similar improvements throughout the rev range.

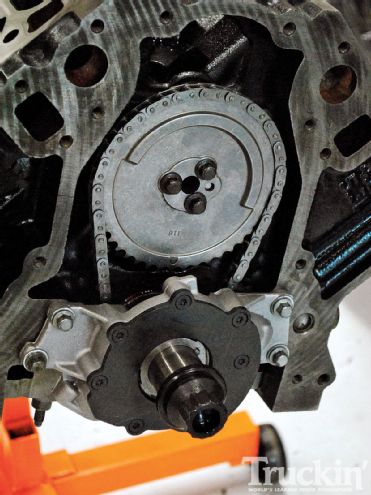

Chevy truck enthusiasts who grew up on the conventional 23-degree small-block will no doubt recognize the 383ci displacement we had planned for our 5.3L, but the LS combination is a different animal altogether. The 5.3L (roughly 324 cubic inches) combines a 3.78-inch bore with the 3.62-inch stroke shared with most of the LS family (4.8L shares common bore with a shorter stroke). The cylinder wall in the iron 5.3L block limits boring beyond 3.902, so the 5.3L stroker cannot share the 4.030 x 3.75 dimensions offered by the conventional 383ci small-block Chevy. Instead, the 383ci displacement is achieved by combining the 3.902 bore with a 4.00-inch stroker crank (and 6.2-inch forged steel rods) from Pro Comp Electronics. The increase in bore size from 3.78 to 3.902 also gave us the opportunity to try another set of cylinder heads. While the GenX 205 heads were likely every bit as effective, even on this larger 383ci, we selected a set of ported 5.3L castings from Total Engine Airflow. In stock trim, the 5.3L castings offer flow numbers near 245 CFM on the intake and 180 CFM on the exhaust. Treated to Stage 2 porting, the revised TEA 5.3L heads offered an amazing 314 CFM on the intake and 261 CFM on the exhaust. These changes were made with minimal (as possible) changes in port volume. Despite the slight increase in port volume, the more than commensurate increase in airflow actually produced an increase in port velocity. This means the TEA-ported heads should offer substantial power gains throughout the rev range compared to stock 5.3L heads. The impressive flow numbers offered by the TEA 5.3L head had no trouble supporting our 383ci.

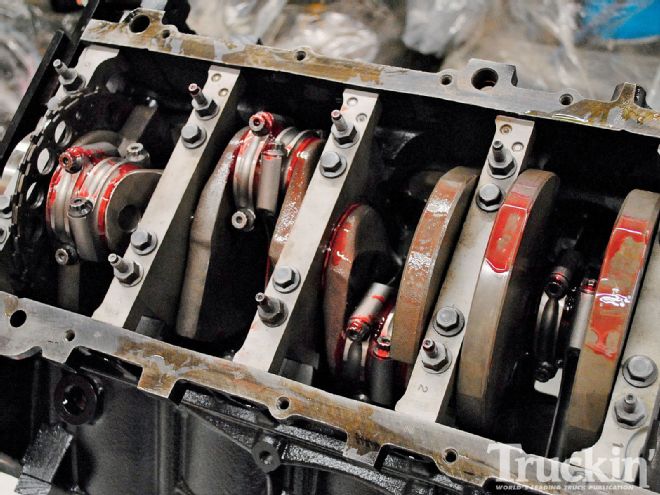

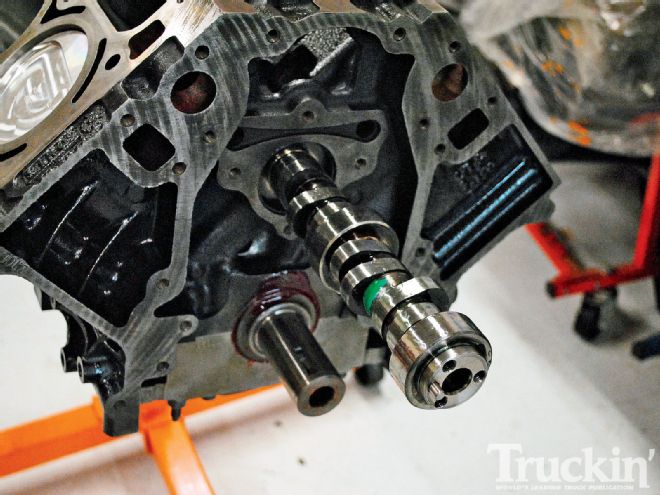

L&R Automotive was responsible for machining the 5.3L iron block to accept the Pro Comp 4.0-inch stroker crank, 6.20-inch forged steel rods and forged pistons from Probe Racing. We selected a set of 21cc dished pistons from Probe Racing for our 383ci to match the 9.5:1 static compression ratio of the stock 5.3L. This was done to allow us to install the supercharger after running the stroker combination. Were this a dedicated normally aspirated engine, we'd opt for a slight increase above 10.0:1, but the 9.5:1 will run well both normally aspirated or with the blower at lower boost levels on pump gas. The 383ci stroker from L&R and Demon Engines received the same Trick Flow Track Max cam run previously in the modified 5.3L. The factory oil windage and oil pan worked on this application, though it was necessary to space and/or hammer form the factory windage tray for stroker crank clearance. The TEA-ported heads were installed using ARP head studs and Fel Pro head gaskets. Though not required for a typical normally aspirated combination, the added insurance was welcome once we installed the supercharger.

For this first test, the 383ci stroker was equipped with the stock truck intake and throttle body, a set of 36-pound injectors and run with the FAST XFI management system. After the break-in procedure, the engine was tuned by Westech's Ernie Mena and eventually produced peak numbers of 480 HP at 5,700 rpm and 491 lb-ft of torque at 4,500 RPM. Torque production for the 383ci exceeded 450 lb-ft from 3,600 RPM to 5,800 RPM. Remember, this compares to a peak of 438 lb-ft from the modified 5.3L. In fact, the stroker equaled the peak torque production of the modified 5.3L (438 lb-ft) at just 3,100 RPM. The larger 383ci demonstrated why strokers are so efficient at enhancing torque production, but we weren't done yet. The first test was to swap out the stock truck intake for the new 102mm LSXRT. Replacing the stock truck intake with the LSXRT increased the peak numbers to 510 HP and 508 lb-ft of torque, gains of 30 HP and 17 lb-ft of torque over the stock intake. As impressed as we were about the significant peak power and torque gains, we were every bit as impressed with the fact that the LSXRT offered more power and torque through the entire rev range. The LSXRT never lost any power compared to the factory truck intake!

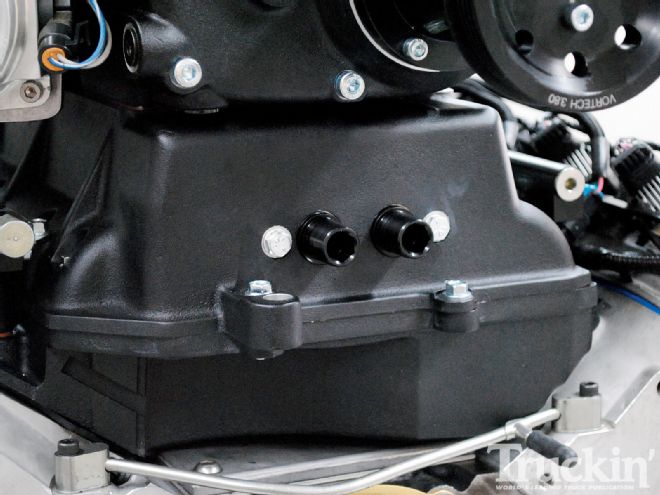

The 5.3L stroker now offered over 500 lb-ft of torque, bettering the peak torque output of the modified 5.3L at just 3,000 RPM. This was now one serious truck engine, but we weren't quite finished. Understanding that truck enthusiasts are always looking for more, we decided to give them exactly that. To further pump up the torque production, we opted for the tried and true method of boost production. If there is one replacement for displacement, it is forced induction. Filling that bill was a 2.3L twin-screw supercharger from Vortech Engineering. Vortech chose the twin-screw design for truck applications for two reasons, the immediate boost response offered by the positive displacement configuration and the superior efficiency compared to a typical roots blower. The Vortech twin-screw kit for the 5.3L featured a Lysholm 2300 (2.3L displacement) supercharger set up to provide near 8 PSI of boost to an otherwise stock engine. Additional features offered by the standard Vortech twin-screw kit included a dual-pass, air-to-water intercooler, high-flow bypass valve, and a cast-aluminum inlet tube to connect the stock throttle body to the supercharger. Also included was a roto-molded air inlet tube, a complete fuel management system and even a 3-year/36,000 mile limited warranty.

We also took the liberty of replacing the 36-pound injectors with a set of larger 50 pounders (run at 60 PSI), allowing us enough fuel to exceed 800 HP if need be. Run with the ATI (stock diameter) crank pulley, the 3.8-inch blower pulley and stock throttle body, the supercharger managed to provide only 2.5 PSI of boost to our ultra-efficient 383ci stroker. Swapping over to the smaller 3.0-inch pulley netted the desired peak boost level of 7.8 PSI at 6,000 rpm. Installation of the Vortech TS supercharger also required use of the complete FEAD front accessory drive including the manual water pump.

Visually the Vortech twin-screw supercharger made an impressive statement. We knew the forged internals from Pro Comp used in the 383ci were plenty capable of harnessing the power offered by the supercharged configuration and after tuning, we were rewarded with peak numbers of 671 HP at 5,800 rpm and 658 lb-ft of torque at 4,600 RPM. There was certainly more power to be had with more boost pressure, but we were quite happy at this point with the fact that torque production from the supercharged stroker exceeded 630 lb-ft from 3,000 RPM to 5,600 RPM, making for one sweet torque curve. Combining the supercharger and stroker improved the power output of the original 5.3L by over 300 HP and nearly a like amount of torque. Of course there is always more boost, as the Vortech system featured a dedicated air-to-water intercooler and would easily continue to cool the charge temperatures offered by another few pounds of boost. Either way, this supercharged stroker clearly demonstrated that not only is boost a replacement for displacement, but also maximum torque comes from combining both!

DYNO POWER NUMBERS

RPM

Stock LM7 (HP TQ)

Modified LM7 (HP TQ)

383ci Stock Intake (HP TQ)

383ci LSXRT (HP TQ)

383ci Vortech (HP TQ)

2900 187 339

199 360

3100 202 343

213 361 258 437 260 441 371 629

3300 218 347

228 363 271 431 275 437 400 636

3500 233 350

247 371 297 446 301 452 430 646

3700 249 353

272 386 325 461 332 471 459 652

3900 267 360

293 395 352 474 361 486 484 651

4100 287 368

317 406 373 478 384 492 509 652

4300 305 373

343 419 399 487 405 495 537 656

4500 315 368

369 431 421 491 432 504 563 658

4700 328 366

390 436 438 489 454 508 588 657

4900 340 364

408 437 455 487 471 505 606 649

5100 344 354

426 439 466 480 483 497 626 644

5300 344 341

442 438 472 468 495 490 644 638

5500 345 329

458 437 479 457 506 483 657 627

5700 348 319

469 432 480 442 510 470 669 617

5900 341 304

476 423 475 423 500 445 671 595

6100 337 290

481 414 467 402 486 419 665 572

6300 330 275

482 402

6500

MAX. 348 373

483 439 480 491 510 508 671 658

FROM THE DRIVER SEAT

The humble little 5.3L has gone through quite a progression, starting at 346 HP and 373 lb-ft of torque. The modifications to the original 5.3L covered previously in part one upped the power ante to 483 HP and 438 lb-ft of torque. Looking to increase torque production, we stepped up to the 383ci stroker, which increased the peak numbers to 480 HP and 491 lb-ft of torque. Replacing the stock truck intake with the new LSXRT from FAST resulted in impressive gains. The new totals stood at 510 HP and 508 lb-ft of torque. Installation of the Vortech twin-screw supercharger put the final tally at 671 HP and 658 lb-ft of torque. Though more power is obviously available with increased boost and or wilder cam timing, this combination offered exceptional idle quality and low-speed torque production-perfect for a performance truck application.

YOUR QUESTIONS ANSWERED

Time Spent Working: 14 hours

Degree of Difficulty: Advanced

Tools Needed:

8,10,12,13, 15mm socket, in-lb torque wrench, lb-ft torque wrench, gear puller, flare nut wrenches

Parts Used:

ATI Performance Products harmonic balancer 917286

$456.02

Trick Flow GenX 202 CNC heads 30500001

$1,995.95

Trick Flow TrackMax cam 30602002

$349.95

Total Engine Airflow Stage 2 LS1 heads for 5.3L

$1,699.80

FAST LSXRT intake manifold 146602

$994.95

FAST 102mm Big Mouth throttle-body

$556.95

Vortech Superchargers twin-screw supercharger 2310010

$5,023.00

Wilson LSX fuel rails 422031

$207.95

Total: $11,284.57

(All prices from summitracing.com or manufacturers, do not include tax, shipping, or installation. It should also be noted that not all parts are listed. For more information, contact the sources.)