The ’03½ to ’07 6.0L Power Stroke engines (which were also used in E-Series vans until ’09) have terrible reputations for reliability and repair costs among diesel enthusiasts. You’ve no doubt heard the horror stories about blown 6.0L head gaskets, fuel system problems, and turbo failures.

| Bullet Proof Diesel’s Jacob Lopez walked us through the install of BPD’s EGR and engine oil cooler systems on this ’05 E-350 with 133,000 miles. It turns out the 6.0L van is slightly different than the pickup version. The vans use a smaller radiator and intercooler and they were built in Ohio—instead of Kentucky where the Super Dutys go together.

They’re Not Junk

While the 6.0L isn’t a perfect engine, what your Cummins and Duramax buddies won’t admit to is these engines are far from junk. The 6.0L (based on International’s VT365 engine) was a technological marvel when it debuted in 2003, and it was the first engine American pickup buyers could get with digitally controlled injection, exhaust gas recirculation (EGR), and a variable-geometry turbo.

The 6.0L’s complexity even exceeded that of the original ’01 to ’03 LB7 Duramax. Readers should also know the 6.0L was designed to be produced in greater volumes than any other diesel made since WWII. When you mix Ferrari-like intricacy with millions of parts going together on two different assembly lines (in two different states!)—there are bound to be growing pains.

Stick With the Experts

When selecting a shop to work on your truck, find a place where the technicians drive 6.0Ls. As complex as these engines are, it’s critical the mechanics know (and care about) what they’re doing. The right shop will have at least one Super Duty with the cab off the frame when you stop by to get an estimate.

| Lopez spent most of his time working with one hand on a flashlight, and the other reaching into the engine to disconnect stuff. The turbo was removed through the van’s doghouse, then the oil filter hard lines, turbo pedestal, and the hose to the EGR cooler were loosened.

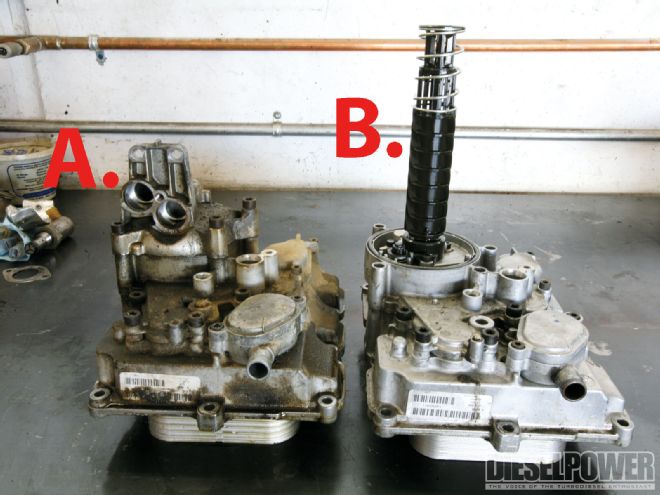

One of the most experienced 6.0L shops in the country is Bullet Proof Diesel (BPD) in Mesa, Arizona. Started by Gene and Ken Neal, BPD began as a full-service auto and diesel repair business, yet it’s come to specialize in Power Stroke trucks due to the brothers’ personal quest to find a permanent fix for failed 6.0L EGR coolers. Bullet Proof Diesel’s lifetime-warranty, TIG-welded EGR coolers have put an end to EGR cooler failures once and for all. But the Neal brothers didn’t stop there.

Air-To-Oil Cooler Kit

Like most diesel engines, the Ford 6.0L uses an oil-to-engine- coolant heat exchanger to cool the engine’s oil. Using coolant is a very efficient way to remove heat from the oil. However, the oil in a 6.0L Power Stroke is the hardest working oil in diesel. It not only lubricates the engine and cools the pistons, it’s also used as a hydraulic fluid to drive the high-pressure fuel injection system. While most diesel oil gets exposed to no more than 60 psi of pressure, the oil in a 6.0L gets routinely punished by pressures of more than 3,000 psi. That pressure makes a ton of heat!

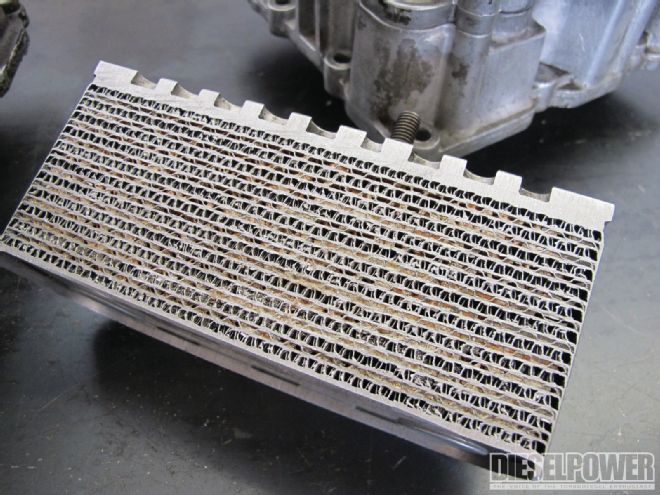

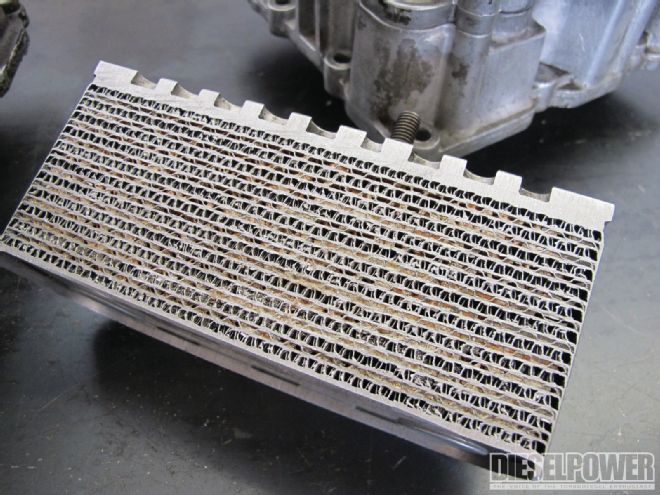

Dealing with the heat is the job of the factory stacked-plate oil cooler mounted in the lifter valley of the engine. In an ingenious attempt to eliminate oil leaks, International designed the 6.0L’s oil system with no external lines or fittings. This is great for leaks but makes it hard to rid the oil of heat. Add to that the fact that these coolers tend to plug up with contamination, and your 6.0L’s oil system can reach meltdown temperatures.

Bullet Proof Diesel now offers a solution for that problem as well. The BPD air-to-oil cooler kit has been installed on our company’s 6.0L F-250 for years now, but when BPD adapted its kit for use on 6.0L vans, we headed over to Mesa to find out more.