1973 Chevy C10 Buildup - The Pickup Fix-Up Tour

Blown Away

It may seem odd to put a carburetor onto a modern engine like the 5.3L LS327, but last summer we did anyway, just to see how it would perform and to simplify an LS engine swap in a '73 Chevy C10. We put about 6,000 miles on the C10 during that time, averaging 17 miles per gallon with a Holley Street Avenger 650 cfm carb, Edelbrock Performer intake manifold, and an MSD 6MLS ignition system firing the spark plugs. The engine put 311 horsepower to the wheels of the C10 through a Gearstar Performance-built 4L65-E overdrive tranny coupled to a stock 12-bolt rear axle with 3.07 gears. It was a smooth and efficient package on the highway, but provided limited excitement when the go-pedal was mashed to the floor.

| 1973 Chevy C10 Buildup burnout

Certainly, a gear ratio change was in order if we were going to gain anything in the acceleration department, but that might have decreased our fuel efficiency if we got too aggressive with the gear selection. We wondered what would happen if we left the drivetrain alone and simply gave the engine a boost in power. Let's just say we found out what happens and it required a posi unit afterwards! A supercharger was the natural answer to quickly putting more ponies to the ground without diving into the internals of the engine and Whipple Superchargers had just the answer. The company's 2.3L intercooled blower and a fuel-injection system designed for longevity and room to grow later on, gave us much-needed reliability and smooth operation while putting an ass-whooping on our tires.

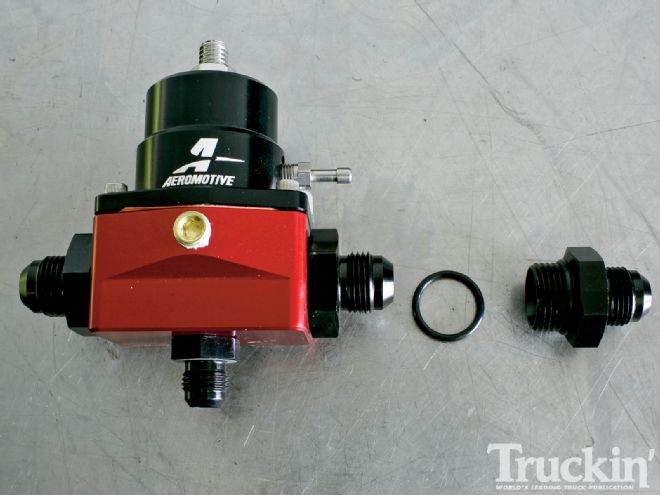

Since the engine was originally fed fuel and air via a carburetor and the factory fuel system, we'd need to address that issue before going forward with the parts swap. We took the truck to PPC Customs in Clovis, California, to make the complete conversion happen. While we were at it, our old C10 had a pair of saddle gas tanks mounted beneath the cab that we also wanted to eliminate. By installing a No Limit Engineering fuel cell behind the rear axle, we were able to shift some weight to the rear of the truck, where it's needed, for improved handling and traction. To push fuel from the aluminum cell up to the fuel injectors, we installed an Aeromotive A1000 electric continuous-duty fuel pump and two-port bypass regulator. This system provides rock-solid fuel pressure to the injectors by bypassing any unneeded fuel to a return line plumbed back to the fuel cell. Unlike a "dead head"-style regulator, there is no pressure creep when full fuel flow isn't required by the engine. The regulator is also boost-referenced to a MAP sensor, which tells it when the blower has overcome atmospheric pressure inside the intake manifold and when the engine requires additional fuel.

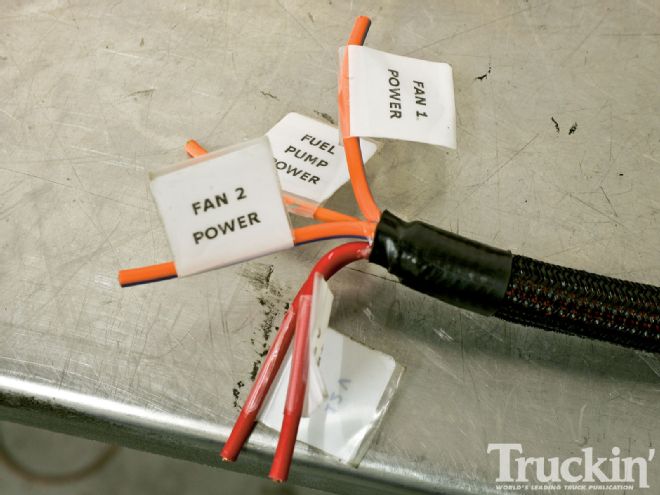

Once the new fuel system was in place, the blower install took a relatively small amount of time. We added the heat exchanger, supercharger, and a new computer and ignition system in the span of a weekend, making this a conversion that anyone could likely do at home. We tapped Bob Radke from MEFIBURN.com to tune our Painless Performance MEFI4-based computer and were astounded at the results. Here's a look at how we injected a new personality into our C10.