| bd Diesel Super B Install engine Bay

In a diesel engine, adding more fuel will almost always result in more horsepower, and last month, that's exactly what we did in our "Fuel It Up!" article. There are drawbacks to making power in this manner, though, as exhaust gas temperatures (EGT) will start reaching dangerous levels, and particulate (black smoke) will be very high. That's why this month's installment of Project 12-Valve is about upgrading the turbo from a stock unit to BD Diesel's Super B. By adding more boost to the mix, we were hoping to reduce our 1,500-degree-F EGT, reduce smoke, and make more power.

We not only added a turbo, but we also tackled air restrictions everywhere else by putting on a new exhaust manifold, an intake, and freeing up our exhaust system. With our engine's airflow unrestricted, we also put in a 3,000-rpm governor-spring kit to let our engine rev higher. The theory is that with the new turbo, we'll create a broader, more usable power curve.

After watching a few competitors have a very hard time spooling their turbos at this year's Diesel Power Challenge, we chose BD's quick-spooling and responsive Super B turbo, which is good for both street driving and towing. While the stock turbo can be made to produce more boost, the air temps exiting the turbo will be much higher, and the turbo may be prone to surging. The Super B also produces a greater volume of air, something that must also be considered when choosing a turbocharger.

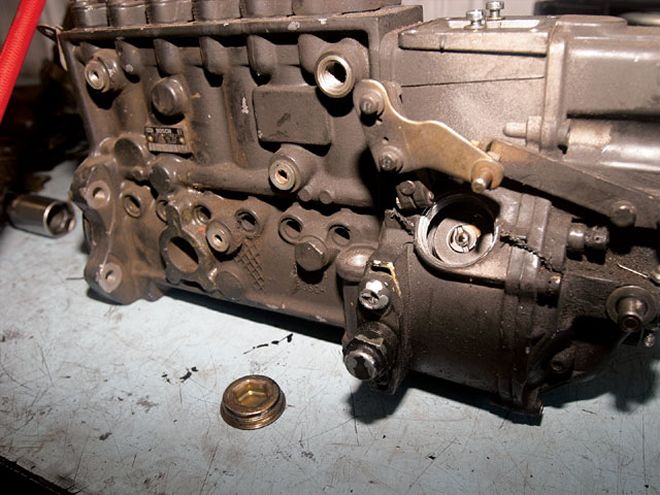

To help spool the Super B, promote good exhaust flow, and safeguard against cracking, we installed BD's three-piece exhaust manifold. On the intake side of things, we put on BD's Power-X intake, and although right now it's only available for 24-valve applications ('98-'02), we made it work with some minor fiddling on our 12-valve. Because we were on a dyno and weren't worried about California emissions laws, we chose the least restrictive exhaust available: a straight 4-inch pipe from the turbo to about the middle of the truck.

With the truck on the dyno, the first thing we noticed was the immense increase in boost. While our stock turbo had been making about 22 psi, the new Super B made 40 psi, which resulted in more torque down low (like we hoped) as well as more power up high. EGT dropped somewhat, although the temperatures were still in the 1,350-1,400-degree range on almost every pull. The important part, though, was that we could actually run through the gears on this setup (Overdrive included) without reaching our 1,500-degree cutoff point.

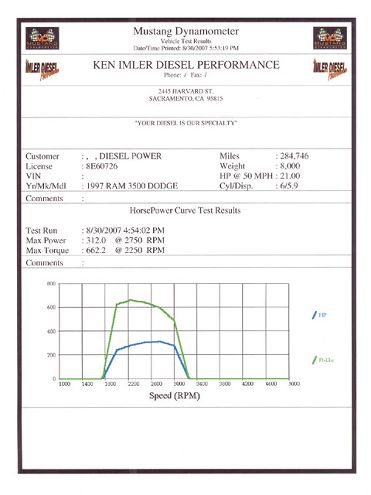

Last month, our truck made 272 hp at the rear wheels and 636 lb-ft of rear-wheel torque with our fueling upgrades, and this month, we added more and moved the power curve upward. The peak horsepower came at 2,750 rpm compared with the former peak at 2,250 rpm. With the new mods, the truck made 312 hp at the rear wheels and 662 lb-ft of torque, a gain of 40 hp and 26 lb-ft. We tried hooking the exhaust back up, and oddly enough, going from a straight 4-inch pipe to a 3-inch with a muffler and a catalyst only dropped us 12 hp, but EGT shot back up to 1,450-1,500 degrees with the stock piping in place.

What did we learn from our airflow experience? Our 40 pounds of boost from the turbo showed we had a lot of airflow potential, so in our next installment, we'll be adding an intercooler and tuning the fuel curve to try to get the EGT down to a safe 1,300 degrees and get 350 hp to the rear wheels.

| bd Diesel Super B Install engine Bay

In a diesel engine, adding more fuel will almost always result in more horsepower, and last month, that's exactly what we did in our "Fuel It Up!" article. There are drawbacks to making power in this manner, though, as exhaust gas temperatures (EGT) will start reaching dangerous levels, and particulate (black smoke) will be very high. That's why this month's installment of Project 12-Valve is about upgrading the turbo from a stock unit to BD Diesel's Super B. By adding more boost to the mix, we were hoping to reduce our 1,500-degree-F EGT, reduce smoke, and make more power.

We not only added a turbo, but we also tackled air restrictions everywhere else by putting on a new exhaust manifold, an intake, and freeing up our exhaust system. With our engine's airflow unrestricted, we also put in a 3,000-rpm governor-spring kit to let our engine rev higher. The theory is that with the new turbo, we'll create a broader, more usable power curve.

After watching a few competitors have a very hard time spooling their turbos at this year's Diesel Power Challenge, we chose BD's quick-spooling and responsive Super B turbo, which is good for both street driving and towing. While the stock turbo can be made to produce more boost, the air temps exiting the turbo will be much higher, and the turbo may be prone to surging. The Super B also produces a greater volume of air, something that must also be considered when choosing a turbocharger.

To help spool the Super B, promote good exhaust flow, and safeguard against cracking, we installed BD's three-piece exhaust manifold. On the intake side of things, we put on BD's Power-X intake, and although right now it's only available for 24-valve applications ('98-'02), we made it work with some minor fiddling on our 12-valve. Because we were on a dyno and weren't worried about California emissions laws, we chose the least restrictive exhaust available: a straight 4-inch pipe from the turbo to about the middle of the truck.

| bd Diesel Super B Install engine Bay

In a diesel engine, adding more fuel will almost always result in more horsepower, and last month, that's exactly what we did in our "Fuel It Up!" article. There are drawbacks to making power in this manner, though, as exhaust gas temperatures (EGT) will start reaching dangerous levels, and particulate (black smoke) will be very high. That's why this month's installment of Project 12-Valve is about upgrading the turbo from a stock unit to BD Diesel's Super B. By adding more boost to the mix, we were hoping to reduce our 1,500-degree-F EGT, reduce smoke, and make more power.

We not only added a turbo, but we also tackled air restrictions everywhere else by putting on a new exhaust manifold, an intake, and freeing up our exhaust system. With our engine's airflow unrestricted, we also put in a 3,000-rpm governor-spring kit to let our engine rev higher. The theory is that with the new turbo, we'll create a broader, more usable power curve.

After watching a few competitors have a very hard time spooling their turbos at this year's Diesel Power Challenge, we chose BD's quick-spooling and responsive Super B turbo, which is good for both street driving and towing. While the stock turbo can be made to produce more boost, the air temps exiting the turbo will be much higher, and the turbo may be prone to surging. The Super B also produces a greater volume of air, something that must also be considered when choosing a turbocharger.

To help spool the Super B, promote good exhaust flow, and safeguard against cracking, we installed BD's three-piece exhaust manifold. On the intake side of things, we put on BD's Power-X intake, and although right now it's only available for 24-valve applications ('98-'02), we made it work with some minor fiddling on our 12-valve. Because we were on a dyno and weren't worried about California emissions laws, we chose the least restrictive exhaust available: a straight 4-inch pipe from the turbo to about the middle of the truck.