| motor Oil Science oil Drip

There are a few ways to tell what is happening inside a diesel engine without taking it apart. There are two that you can do in your driveway: looking in the tailpipe and having the engine oil scientifically analyzed.

Getting ScientificKnown as oil analysis, it's a procedure that's very common in the military and with large, expensive engines such as those used in aviation and farming applications. Many trucking companies employ oil analysis as a quick and inexpensive window into the engines put to work in their fleets.

Using microscopic and spectrum analysis, the engine oil can reveal the condition of bearings, fuel contamination, moisture content, and antifreeze dilution. The study also looks for silicon, iron, chromium, aluminum, copper, lead, tin, nickel, and silver. All these metals are used in some form as consumables in the engine such as in the piston rings and bearings, so high levels can tell you when an internal part needs to be replaced.

| motor Oil Science oil Tube

Understanding OilKeeping a diesel engine lubricated poses many different problems. The friction between surfaces is reduced by the presence of oil. The function of engine oil is to displace the two surfaces and reduce the mechanical interference. The oil should be able to adhere to each surface yet be amenable to displacement.

The viscosity of a lubricant helps to drag the fluid into the separating space between the bearings and then retards its escape when the squeezing action brings the two surfaces together. The term "viscosity index" is a measure of the viscosity/temperature behavior of an oil, based on an arbitrary scale of 0-100, with 0 being representative of an oil that thins down rapidly when heated and 100 being representative of an oil that thins less rapidly. Because of these effects, a pressure is created in the lubricant. This pressure can be induced and maintained by employing a wedge action within the bearing surface.

Oil at the CrankshaftWhen an engine is not running, the crankshaft rests on the bearings. When the engine starts and oil pressure is created, the crankshaft moves up off the bearings and pulls some oil under it. As the crankshaft rotation continues, the oil is wedged between the shaft and bearing, keeping them separated.

As engine speed and loads change, the position of the crankshaft, with respect to the bearings, also changes. Under certain conditions, the mating surfaces may actually break through the oil wedge. There is still enough of an oil film to prevent scoring but not enough to keep the crankshaft and the bearing completely separated. Don't confuse the designed oil clearance with the space between the crankshaft and bearing made by the oil wedge. The oil film is approximately 0.0001-inch, while the machined clearance for a main or connecting rod bearing is usually between 0.004-0.006-inch.

The engine oil then needs to support the pressure load placed upon it as the flame in the cylinder expands and sends the piston down in the bore. The higher the viscosity index number (what we define as weight), the greater the load the oil wedge can support, because its escape from the clearance area is hindered by friction.

Oil GradesThe American Petroleum Institute (API) along with the Society of Automotive Engineers (SAE) are responsible for determining both test and grading standards for oil. The viscosity index can be listed as SAE 15W-40 or some other group of numbers. In contrast, the test standard the oil conforms to is listed with the API prefix-API CI-4/SL, for example.

The additives are what make each brand, not the oil. Motor oil is considered to be fungible, which means that it is so alike in composition that different brands can be mixed together without a problem. But most petroleum chemists will tell you they don't like to mix brands and models of oil. That is simply due to the additives becoming diluted, not because of the base oil product.

Most modern diesel engine oils are classified as multi-grade, which indicates the oil has the characteristics of two different viscosity indexes. Since the temperature of the engine and oil changes from startup to maximum operating load, a multi-grade oil is required. When oil is cold, its viscosity changes and it becomes thicker. When heated, the viscosity index number drops and the oil thins.

For example, a 15W-40 oil would flow with the characteristics of 15-weight when cold but will maintain the oil cushion properties of 40-weight when heated. Even though this is the accepted definition of a multi-grade, the product is a compromise and doesn't have the absolute flow characteristics of a single grade oil of either weight. Therefore, you can't buy a can of straight 15W and 40W oil and mix them together to create a multi-grade of your own.

-

-

Severe Duty

Most street-driven diesels can be categorized as severe duty, even if your foot has never gone more than halfway to the floor. Numerous cold starts and short trips introduce fuel and moisture into the crankcase and are killers of any oil. Diesel fuel isn't a great lubricant, and even the smallest amount will reduce the oil's ability to eliminate friction.

The most-asked question about diesel engines is compatibility with the new synthetic grades of oil. A fully synthetic or a combination of mineral/synthetic blend can be used in any engine.

The early synthetics that were introduced approximately 30 years ago had a slightly different swell rate for rubber seals and became known for creating leaks in an engine that had the seals swelled by mineral oil. But that problem has been long corrected, and swell rates are nearly the same for mineral and synthetic oils.

An often-overlooked benefit of synthetic oils is the ability to flow easily and quickly at low temperatures and during engine cranking. This attribute alone will drastically reduce engine wear on a vehicle that experiences many starting cycles and is used for short trips.

Why analyze?

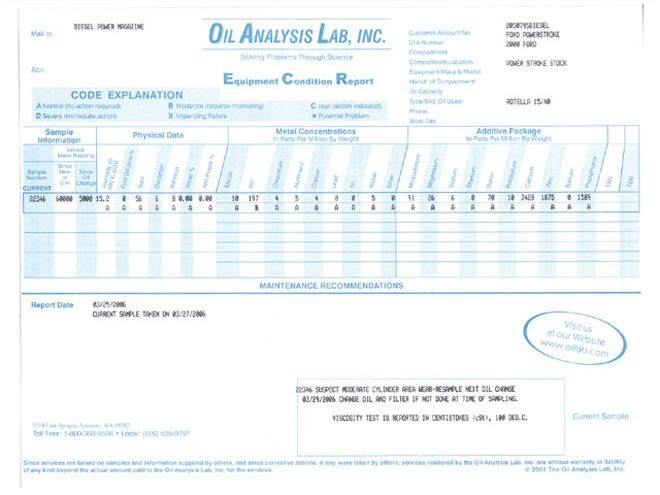

We are proponents of oil analysis and used the services of Lane Crandall and his company, Oil Analysis Lab, Inc. Though commonly associated only with engine oil, analysis of all lubricants is available and should become part of your preventative maintenance schedule. Through science, Oil Analysis Labs, Inc. can determine the health of driveline components, such as the differential and transmission, by studying the specific lubricant. It's much better and cost effective to spot a problem when it's small than to wait until it becomes a costly and potentially large concern. Oil Labs, Inc. provides a detailed report with up to 28 different categories. Don't worry, you don't have to be a scientist to digest the data. There's a complete description of the numeric test results on the back of the printout along with a layperson's interpretation and recommendations for service that need to be performed on your diesel.

When to Get Oil Analysis

It depends on the situation. For the results to be accurate, the oil needs to have seen some use. Crandall recommends the oil be in the engine for at least 2,000 miles for the tests to be valid.

The company also has the resources to analyze the contents of the oil filter to identify wear beyond the standard oil sample testing.

The second element of oil analysis is the ability to track any wear after a baseline is established. Depending on the use of the vehicle, you may choose to have a sample analyzed semi-annually or every other oil change. The Oil Analysis Labs, Inc. database keeps records and comparisons of your samples, and you will be able to determine if a problem is pending. With the cost of the service starting at only $21.50, including the sample bottle and shipping box, it's a viable tool for every diesel enthusiast.

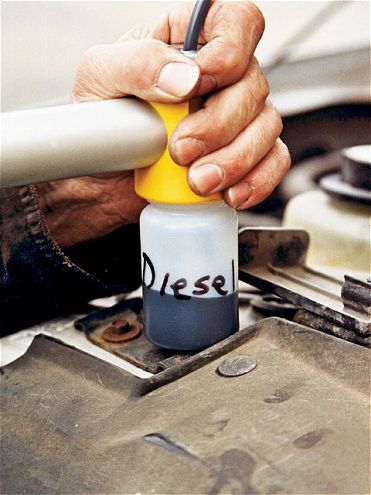

Since the subject F-350 was not ours, we wanted to take a sample without disturbing anything-thus using the extraction-gun method. This tool is available for $42.50 from the test lab. This procedure is appropriate for sampling a vehicle you intend to purchase or an analysis between drain intervals.

| motor Oil Science oil Drip

There are a few ways to tell what is happening inside a diesel engine without taking it apart. There are two that you can do in your driveway: looking in the tailpipe and having the engine oil scientifically analyzed.

Getting Scientific

| motor Oil Science oil Drip

There are a few ways to tell what is happening inside a diesel engine without taking it apart. There are two that you can do in your driveway: looking in the tailpipe and having the engine oil scientifically analyzed.

Getting Scientific | motor Oil Science oil Tube

Understanding Oil

| motor Oil Science oil Tube

Understanding Oil