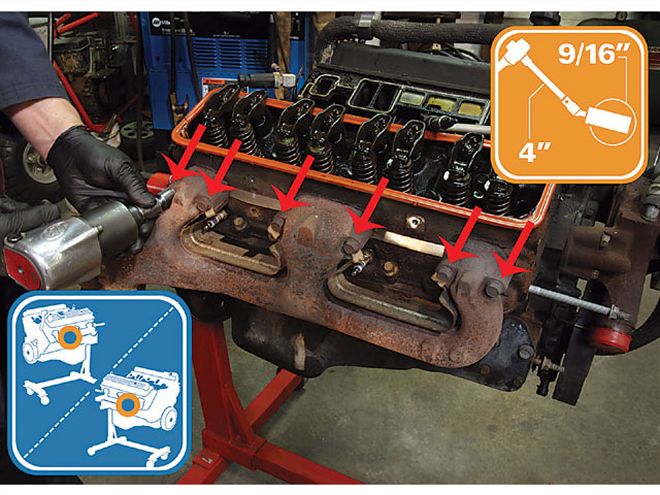

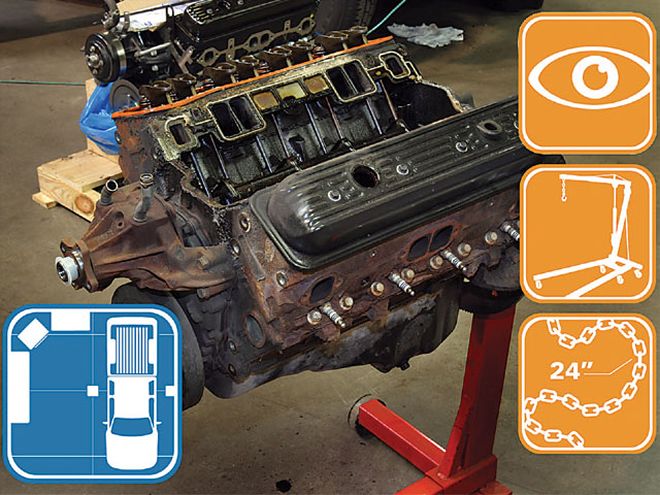

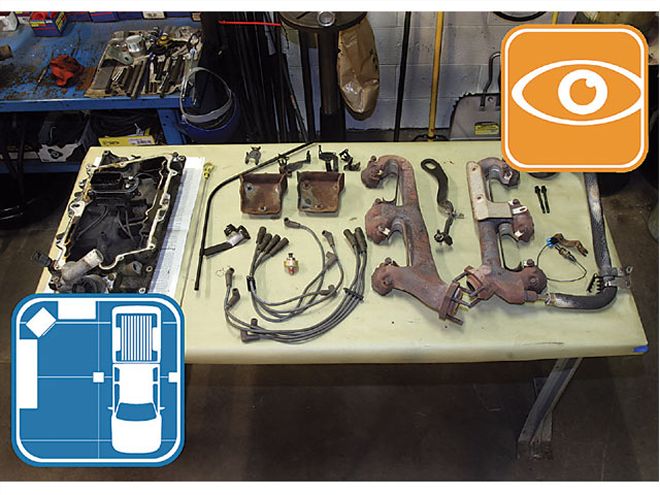

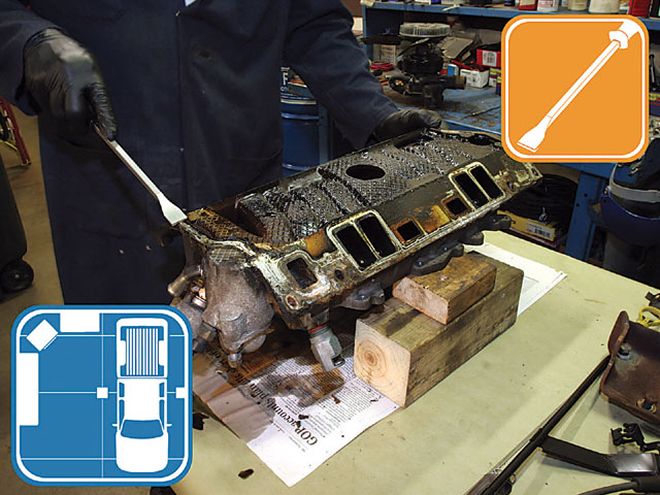

| Once you've pulled the old Vortec engine from your '96-'99 GM truck or SUV, remove the parts needed for the crate engine to get it going in the vehicle. It's best to do this with the old engine on a stand and a table nearby on which to place the parts.

For those who want to step up the performance of their small-block V-8- powered '96-'99 GM truck or SUV, without making a ton of modifications, an easy answer awaits. GM Performance Parts (GMPP) now has a big-cube small-block, called the HT 383E, that will bolt in like a stock V-8 engine, meet emission requirements in most states, and put considerably more power to the ground. Last month we showed you how to remove your old worn-out engine, in this issue we'll show you which parts you need to install on the HT 383E. OK, we'll give the end away: the HT 383E engine produced a triple-digit power improvement to the tires, runs like a stocker, and the truck gets the same fuel mileage as before. Did we mention it was fun to drive, too?

Parts SwapProbably the least documented aspects to swapping a crate engine, in place of a worn-out engine, is knowing which parts to pull off the old engine for reuse, how to prep those parts for more miles, and how to determine what needs to be replaced before assembling them on the new crate engine. This sounds basic, but most enthusiasts are surprised by how often special tools, finesse, or knowledge is needed to get through this part of an engine swap. In this case, we were lucky enough to have the super-detailed Dr. Whaba R&R (Remove & Reinstall) Photoinstructions to follow throughout the process.

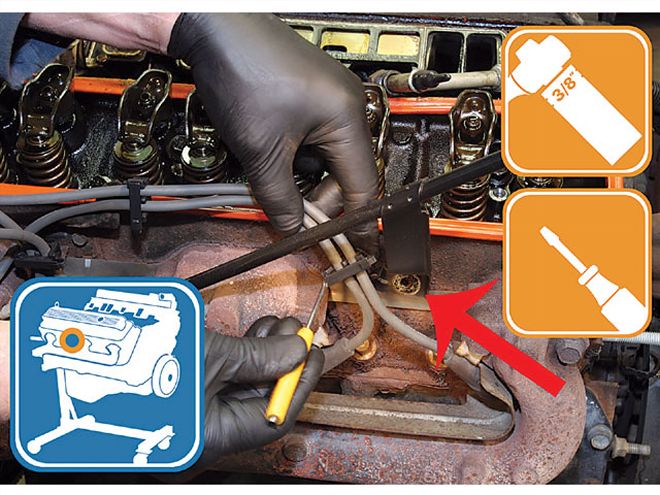

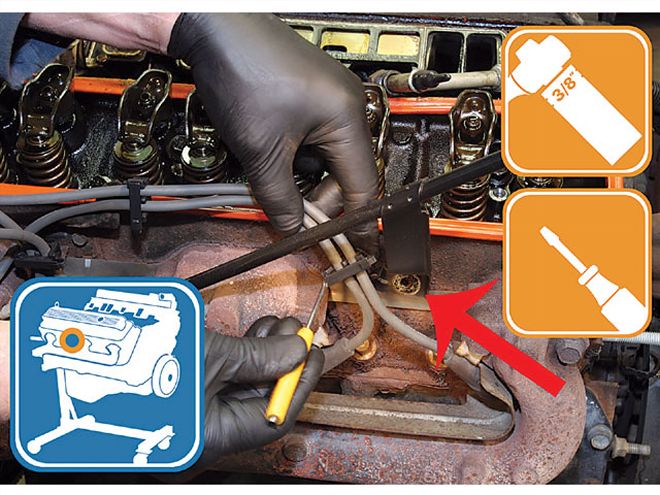

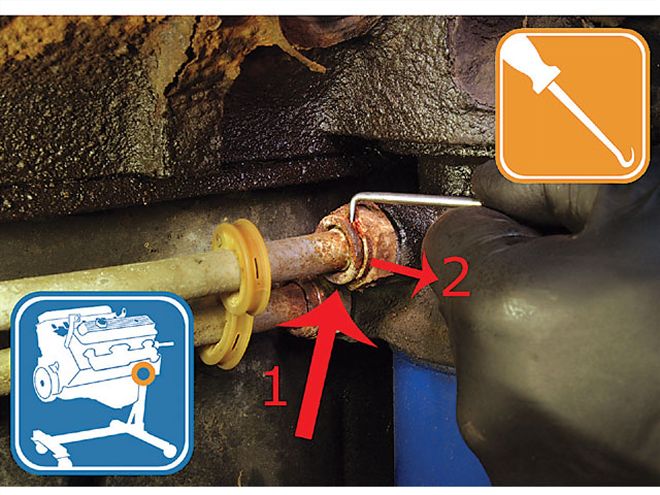

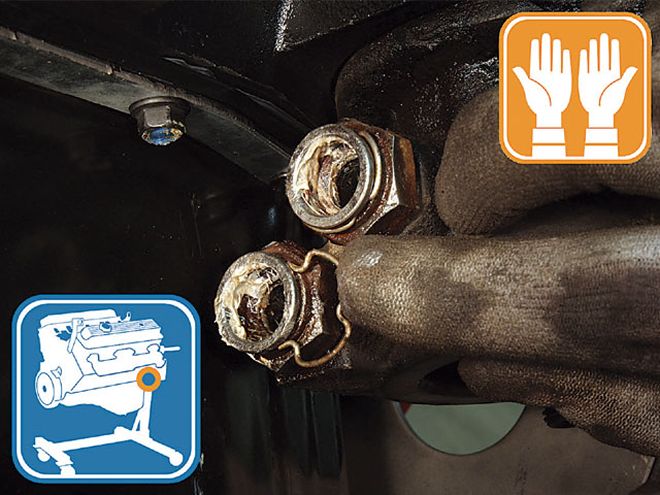

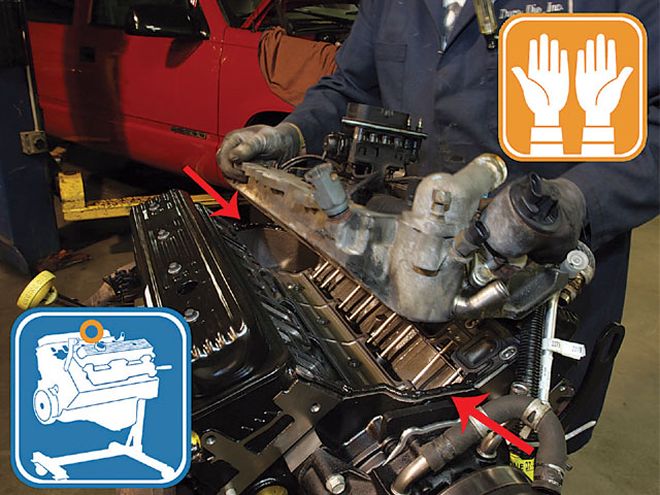

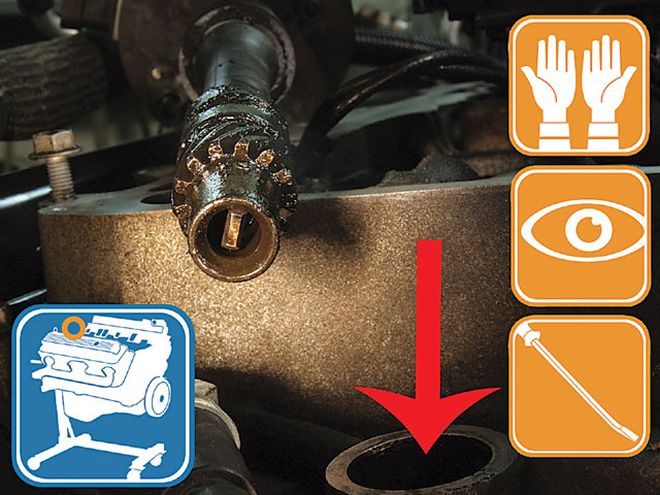

| The install began by stripping the old engine by removing the dipstick tube (arrow pointing to where 3/8-inch bolt holds tube bracket on head), opening the clips on the spark-plug wire loom brackets, and then removing the bolts, which held the brackets on the engine.

Engine Drop-InGetting the GMPP HT 383E crate engine into the vehicle requires some heavy-duty tools, like an engine hoist, a floor jack, jackstands, and the help of a friend or two. After all the work to get the old engine out and prep the new engine, the reinstall didn't seem like such a big deal and went fairly smooth and fast. If anything, reconnecting all the wiring connectors was a lot easier than removing them.

Making It RunThe start-up and break-in of the new engine went smoothly. We did before and after chassis dyno testing and the HT 383E created impressive power gains in the lower rpm range compared to the stock 350ci Vortec V-8. For example, at 3,400 rpm, the stock 350ci made 111 hp and 72 lb-ft of torque at the wheels. The HT 383E bumped that to 183 hp and 118 lb-ft at the wheels-a lift of 72 horsepower and 46 lb-ft! You could feel this in the seat of your pants when tipping into the throttle.

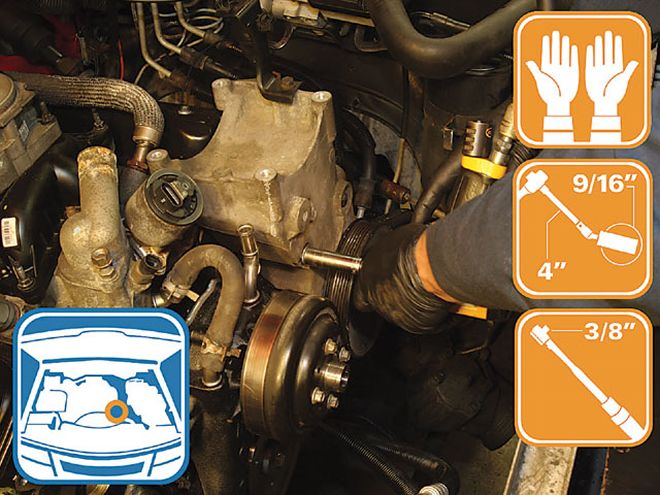

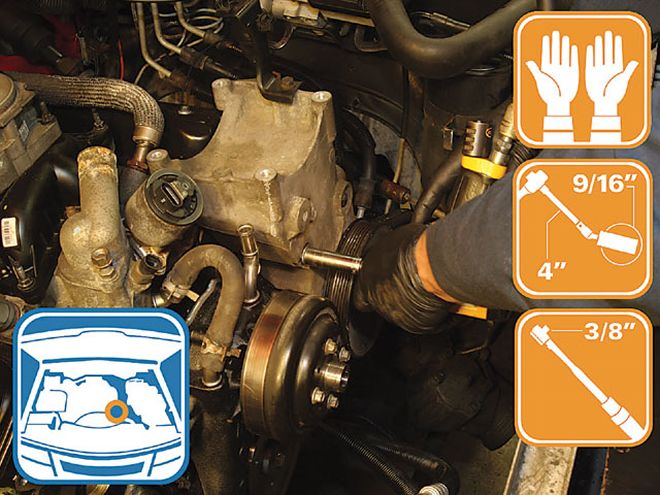

| Sliding the power steering/air conditioning and alternator mounts onto the guide studs and bolting them in place was next. Reattaching the power steering, air conditioning, and alternator units to the hoses, wiring, and bracketry was a breeze.

But, as any performance enthusiast will tell you, "more power is good." So, this truck was shipped off to DynoTech Engineering, Inc. (DTE), in Fort Wayne, Indiana, to have the powertrain control module (PCM) calibrated for the new powertrain combination. DTE has specialized in the C5/C6 Corvette performance vehicle platforms for years, but they also apply their successful computer calibration services to the performance-truck market. DynoTech has done many crate engine PCM calibration tune-ups and did a fantastic job on this HT 383E-equipped truck. The HT 383E definitely lived up to its potential for generating miles of stuff-hauling truck-smiles.

Tuning For PowerGMPP says the factory powertrain control module will run the HT 383E, which it did, but after driving the truck for a few hundred miles we felt there was additional power to be had by having a tuned calibration created and installed. We contacted DynoTech Engineering, in Fort Wayne to have them upload one of its crate engine calibrations into this truck's computer. The result was dramatic.

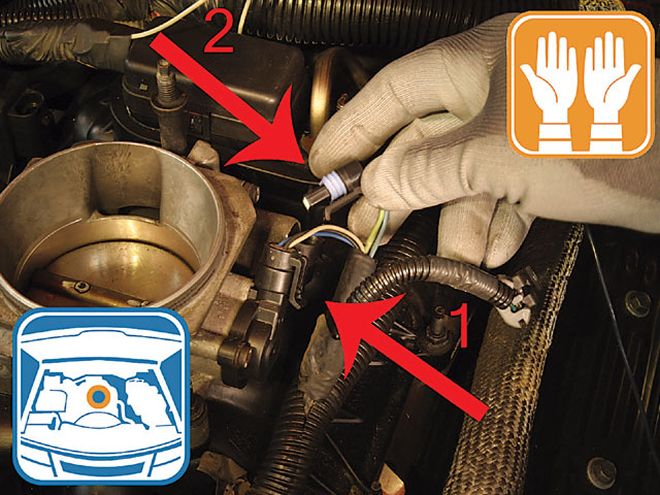

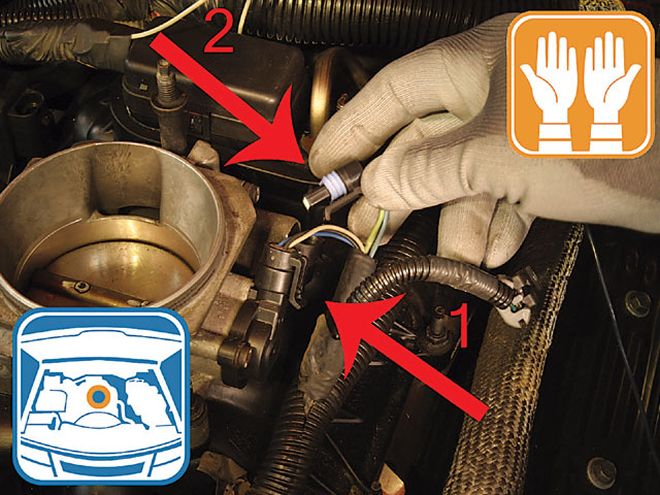

| Connecting the wiring for the throttle-body throttle blade position sensor and idle air-control sensors, along with the wiring for the coil, manifold air pressure sensor, and other electronic sensors was next. We pushed the connectors together until the lock tang snapped into place.

If you don't find peak power gains over the stock controlled HT 383E of 212 horsepower at 4,500 rpm and 150 lb-ft of torque at 3,400 rpm, then you aren't breathing. These aren't the total power numbers-just the additional power DynoTech found!

Even better, the power lift only starts to tell the real story. The new DynoTech calibration reduced the start-on-the-key crank time, smoothed out the cold start idle quality and off-idle throttle tip-in and created a thick, impressive mid-throttle power surge we had not felt before. In all, the truck felt even better than the difference we felt after the HT 383E was installed in place of the original Vortec 350ci engine.

For crate engine upgrades, DTE provides a base PCM calibration for your truck's new engine combination; assuming it's a stock drivetrain other than the crate engine. If you have any additional modifications done to your vehicle, other than what the calibration was written for, you need to take your truck to DTE for a final calibration tuneup or you can take your vehicle to your favorite local tuner so they can tweak the calibration to suit your particular needs.

DTE is one of the few calibration shops out there that can truly create a big hp vehicle that does everything you'd expect an electronically controlled vehicle to do from the factory. This is important for this truck, as it is a hauling, towing, full-season workhorse.

| 1996 Chevy Truck reinstall Serpentine Belt

Parts To Pull Off The Worn-Out Engine/Install On A Crate Engine: Exhaust manifolds and heat shieldsOil cooler/filter mountOil cooler linesTemperature sender for gaugePower steering mount bracket (lower)Oil pressure sender/adapter fittingStuds for alternator and power steering/air conditioning bracketsWater pump/pulleyExhaust gas recirculation (EGR) and fresh air tubesValve cover oil fill tubeCoolant bypass tubeEngine mountsFuel pump blockoff plateDipstick and tubeSpark plug wire brackets and wiresTransmission cooler line bracket on oil panIntake manifold (you'll need new intake gaskets)Valve cover grommetsVarious bolts/conduit clips and brackets

| Installing the coolant hoses and filling the radiator with about 2 gallons of a 50/50 coolant/water mix as an initial amount was last. We were then ready to start the new engine. We ran it at about 2,400 rpm while topping off the coolant system with the 50/50 mix and installing the cap.

Parts To Swap That Were Unbolted During The Engine Removal:

AirboxStarterHarmonic balancerTensioner and idler pulleysTransmission converter coverAlternator and bracketryAir conditioning/power steering pumps and bracketryVarious bolts, conduit clips, and brackets

Parts You Should Replace With New Pieces:

Engine knock sensorEngine oil cooler lines

Consumables Needed For Parts Swaps:

3M Roloc mating surface cleaning pad6 qts of 10W-30 oilRTV sealerThread sealerWhite lithium greaseBrake clean solvent

Specialized Tools:

Oil pressure sensor socketDental pick toolRadiator hook tool8mm inverted Torx socket (also called a Torx E8 socket)

| Once you've pulled the old Vortec engine from your '96-'99 GM truck or SUV, remove the parts needed for the crate engine to get it going in the vehicle. It's best to do this with the old engine on a stand and a table nearby on which to place the parts.

For those who want to step up the performance of their small-block V-8- powered '96-'99 GM truck or SUV, without making a ton of modifications, an easy answer awaits. GM Performance Parts (GMPP) now has a big-cube small-block, called the HT 383E, that will bolt in like a stock V-8 engine, meet emission requirements in most states, and put considerably more power to the ground. Last month we showed you how to remove your old worn-out engine, in this issue we'll show you which parts you need to install on the HT 383E. OK, we'll give the end away: the HT 383E engine produced a triple-digit power improvement to the tires, runs like a stocker, and the truck gets the same fuel mileage as before. Did we mention it was fun to drive, too?

Parts SwapProbably the least documented aspects to swapping a crate engine, in place of a worn-out engine, is knowing which parts to pull off the old engine for reuse, how to prep those parts for more miles, and how to determine what needs to be replaced before assembling them on the new crate engine. This sounds basic, but most enthusiasts are surprised by how often special tools, finesse, or knowledge is needed to get through this part of an engine swap. In this case, we were lucky enough to have the super-detailed Dr. Whaba R&R (Remove & Reinstall) Photoinstructions to follow throughout the process.

| Once you've pulled the old Vortec engine from your '96-'99 GM truck or SUV, remove the parts needed for the crate engine to get it going in the vehicle. It's best to do this with the old engine on a stand and a table nearby on which to place the parts.

For those who want to step up the performance of their small-block V-8- powered '96-'99 GM truck or SUV, without making a ton of modifications, an easy answer awaits. GM Performance Parts (GMPP) now has a big-cube small-block, called the HT 383E, that will bolt in like a stock V-8 engine, meet emission requirements in most states, and put considerably more power to the ground. Last month we showed you how to remove your old worn-out engine, in this issue we'll show you which parts you need to install on the HT 383E. OK, we'll give the end away: the HT 383E engine produced a triple-digit power improvement to the tires, runs like a stocker, and the truck gets the same fuel mileage as before. Did we mention it was fun to drive, too?

Parts SwapProbably the least documented aspects to swapping a crate engine, in place of a worn-out engine, is knowing which parts to pull off the old engine for reuse, how to prep those parts for more miles, and how to determine what needs to be replaced before assembling them on the new crate engine. This sounds basic, but most enthusiasts are surprised by how often special tools, finesse, or knowledge is needed to get through this part of an engine swap. In this case, we were lucky enough to have the super-detailed Dr. Whaba R&R (Remove & Reinstall) Photoinstructions to follow throughout the process.

| The install began by stripping the old engine by removing the dipstick tube (arrow pointing to where 3/8-inch bolt holds tube bracket on head), opening the clips on the spark-plug wire loom brackets, and then removing the bolts, which held the brackets on the engine.

Engine Drop-InGetting the GMPP HT 383E crate engine into the vehicle requires some heavy-duty tools, like an engine hoist, a floor jack, jackstands, and the help of a friend or two. After all the work to get the old engine out and prep the new engine, the reinstall didn't seem like such a big deal and went fairly smooth and fast. If anything, reconnecting all the wiring connectors was a lot easier than removing them.

Making It RunThe start-up and break-in of the new engine went smoothly. We did before and after chassis dyno testing and the HT 383E created impressive power gains in the lower rpm range compared to the stock 350ci Vortec V-8. For example, at 3,400 rpm, the stock 350ci made 111 hp and 72 lb-ft of torque at the wheels. The HT 383E bumped that to 183 hp and 118 lb-ft at the wheels-a lift of 72 horsepower and 46 lb-ft! You could feel this in the seat of your pants when tipping into the throttle.

| The install began by stripping the old engine by removing the dipstick tube (arrow pointing to where 3/8-inch bolt holds tube bracket on head), opening the clips on the spark-plug wire loom brackets, and then removing the bolts, which held the brackets on the engine.

Engine Drop-InGetting the GMPP HT 383E crate engine into the vehicle requires some heavy-duty tools, like an engine hoist, a floor jack, jackstands, and the help of a friend or two. After all the work to get the old engine out and prep the new engine, the reinstall didn't seem like such a big deal and went fairly smooth and fast. If anything, reconnecting all the wiring connectors was a lot easier than removing them.

Making It RunThe start-up and break-in of the new engine went smoothly. We did before and after chassis dyno testing and the HT 383E created impressive power gains in the lower rpm range compared to the stock 350ci Vortec V-8. For example, at 3,400 rpm, the stock 350ci made 111 hp and 72 lb-ft of torque at the wheels. The HT 383E bumped that to 183 hp and 118 lb-ft at the wheels-a lift of 72 horsepower and 46 lb-ft! You could feel this in the seat of your pants when tipping into the throttle.

| Sliding the power steering/air conditioning and alternator mounts onto the guide studs and bolting them in place was next. Reattaching the power steering, air conditioning, and alternator units to the hoses, wiring, and bracketry was a breeze.

But, as any performance enthusiast will tell you, "more power is good." So, this truck was shipped off to DynoTech Engineering, Inc. (DTE), in Fort Wayne, Indiana, to have the powertrain control module (PCM) calibrated for the new powertrain combination. DTE has specialized in the C5/C6 Corvette performance vehicle platforms for years, but they also apply their successful computer calibration services to the performance-truck market. DynoTech has done many crate engine PCM calibration tune-ups and did a fantastic job on this HT 383E-equipped truck. The HT 383E definitely lived up to its potential for generating miles of stuff-hauling truck-smiles.

Tuning For PowerGMPP says the factory powertrain control module will run the HT 383E, which it did, but after driving the truck for a few hundred miles we felt there was additional power to be had by having a tuned calibration created and installed. We contacted DynoTech Engineering, in Fort Wayne to have them upload one of its crate engine calibrations into this truck's computer. The result was dramatic.

| Sliding the power steering/air conditioning and alternator mounts onto the guide studs and bolting them in place was next. Reattaching the power steering, air conditioning, and alternator units to the hoses, wiring, and bracketry was a breeze.

But, as any performance enthusiast will tell you, "more power is good." So, this truck was shipped off to DynoTech Engineering, Inc. (DTE), in Fort Wayne, Indiana, to have the powertrain control module (PCM) calibrated for the new powertrain combination. DTE has specialized in the C5/C6 Corvette performance vehicle platforms for years, but they also apply their successful computer calibration services to the performance-truck market. DynoTech has done many crate engine PCM calibration tune-ups and did a fantastic job on this HT 383E-equipped truck. The HT 383E definitely lived up to its potential for generating miles of stuff-hauling truck-smiles.

Tuning For PowerGMPP says the factory powertrain control module will run the HT 383E, which it did, but after driving the truck for a few hundred miles we felt there was additional power to be had by having a tuned calibration created and installed. We contacted DynoTech Engineering, in Fort Wayne to have them upload one of its crate engine calibrations into this truck's computer. The result was dramatic.

| Connecting the wiring for the throttle-body throttle blade position sensor and idle air-control sensors, along with the wiring for the coil, manifold air pressure sensor, and other electronic sensors was next. We pushed the connectors together until the lock tang snapped into place.

If you don't find peak power gains over the stock controlled HT 383E of 212 horsepower at 4,500 rpm and 150 lb-ft of torque at 3,400 rpm, then you aren't breathing. These aren't the total power numbers-just the additional power DynoTech found!

Even better, the power lift only starts to tell the real story. The new DynoTech calibration reduced the start-on-the-key crank time, smoothed out the cold start idle quality and off-idle throttle tip-in and created a thick, impressive mid-throttle power surge we had not felt before. In all, the truck felt even better than the difference we felt after the HT 383E was installed in place of the original Vortec 350ci engine.

For crate engine upgrades, DTE provides a base PCM calibration for your truck's new engine combination; assuming it's a stock drivetrain other than the crate engine. If you have any additional modifications done to your vehicle, other than what the calibration was written for, you need to take your truck to DTE for a final calibration tuneup or you can take your vehicle to your favorite local tuner so they can tweak the calibration to suit your particular needs.

DTE is one of the few calibration shops out there that can truly create a big hp vehicle that does everything you'd expect an electronically controlled vehicle to do from the factory. This is important for this truck, as it is a hauling, towing, full-season workhorse.

| Connecting the wiring for the throttle-body throttle blade position sensor and idle air-control sensors, along with the wiring for the coil, manifold air pressure sensor, and other electronic sensors was next. We pushed the connectors together until the lock tang snapped into place.

If you don't find peak power gains over the stock controlled HT 383E of 212 horsepower at 4,500 rpm and 150 lb-ft of torque at 3,400 rpm, then you aren't breathing. These aren't the total power numbers-just the additional power DynoTech found!

Even better, the power lift only starts to tell the real story. The new DynoTech calibration reduced the start-on-the-key crank time, smoothed out the cold start idle quality and off-idle throttle tip-in and created a thick, impressive mid-throttle power surge we had not felt before. In all, the truck felt even better than the difference we felt after the HT 383E was installed in place of the original Vortec 350ci engine.

For crate engine upgrades, DTE provides a base PCM calibration for your truck's new engine combination; assuming it's a stock drivetrain other than the crate engine. If you have any additional modifications done to your vehicle, other than what the calibration was written for, you need to take your truck to DTE for a final calibration tuneup or you can take your vehicle to your favorite local tuner so they can tweak the calibration to suit your particular needs.

DTE is one of the few calibration shops out there that can truly create a big hp vehicle that does everything you'd expect an electronically controlled vehicle to do from the factory. This is important for this truck, as it is a hauling, towing, full-season workhorse.

| 1996 Chevy Truck reinstall Serpentine Belt

Parts To Pull Off The Worn-Out Engine/Install On A Crate Engine: Exhaust manifolds and heat shieldsOil cooler/filter mountOil cooler linesTemperature sender for gaugePower steering mount bracket (lower)Oil pressure sender/adapter fittingStuds for alternator and power steering/air conditioning bracketsWater pump/pulleyExhaust gas recirculation (EGR) and fresh air tubesValve cover oil fill tubeCoolant bypass tubeEngine mountsFuel pump blockoff plateDipstick and tubeSpark plug wire brackets and wiresTransmission cooler line bracket on oil panIntake manifold (you'll need new intake gaskets)Valve cover grommetsVarious bolts/conduit clips and brackets

| 1996 Chevy Truck reinstall Serpentine Belt

Parts To Pull Off The Worn-Out Engine/Install On A Crate Engine: Exhaust manifolds and heat shieldsOil cooler/filter mountOil cooler linesTemperature sender for gaugePower steering mount bracket (lower)Oil pressure sender/adapter fittingStuds for alternator and power steering/air conditioning bracketsWater pump/pulleyExhaust gas recirculation (EGR) and fresh air tubesValve cover oil fill tubeCoolant bypass tubeEngine mountsFuel pump blockoff plateDipstick and tubeSpark plug wire brackets and wiresTransmission cooler line bracket on oil panIntake manifold (you'll need new intake gaskets)Valve cover grommetsVarious bolts/conduit clips and brackets

| Installing the coolant hoses and filling the radiator with about 2 gallons of a 50/50 coolant/water mix as an initial amount was last. We were then ready to start the new engine. We ran it at about 2,400 rpm while topping off the coolant system with the 50/50 mix and installing the cap.

Parts To Swap That Were Unbolted During The Engine Removal:

AirboxStarterHarmonic balancerTensioner and idler pulleysTransmission converter coverAlternator and bracketryAir conditioning/power steering pumps and bracketryVarious bolts, conduit clips, and brackets

Parts You Should Replace With New Pieces:

Engine knock sensorEngine oil cooler lines

Consumables Needed For Parts Swaps:

3M Roloc mating surface cleaning pad6 qts of 10W-30 oilRTV sealerThread sealerWhite lithium greaseBrake clean solvent

Specialized Tools:

Oil pressure sensor socketDental pick toolRadiator hook tool8mm inverted Torx socket (also called a Torx E8 socket)

| Installing the coolant hoses and filling the radiator with about 2 gallons of a 50/50 coolant/water mix as an initial amount was last. We were then ready to start the new engine. We ran it at about 2,400 rpm while topping off the coolant system with the 50/50 mix and installing the cap.

Parts To Swap That Were Unbolted During The Engine Removal:

AirboxStarterHarmonic balancerTensioner and idler pulleysTransmission converter coverAlternator and bracketryAir conditioning/power steering pumps and bracketryVarious bolts, conduit clips, and brackets

Parts You Should Replace With New Pieces:

Engine knock sensorEngine oil cooler lines

Consumables Needed For Parts Swaps:

3M Roloc mating surface cleaning pad6 qts of 10W-30 oilRTV sealerThread sealerWhite lithium greaseBrake clean solvent

Specialized Tools:

Oil pressure sensor socketDental pick toolRadiator hook tool8mm inverted Torx socket (also called a Torx E8 socket)