| 1996 Dodge Ram 12 Valve Cummins testing Exhaust

As much as we might like the sound and the fury of a big, open exhaust on our diesel engines, does it necessarily flow better than a high-performance aftermarket system? Sure, a big, bad diesel rumble announces your arrival with authority. On a long haul, though, that heavy drone from open pipes can drive you batty, not to mention add to driver fatigue. So we wanted to know if it is possible to have a relatively quiet exhaust that still performs well? Or maybe even better?

To get to the bottom of these issues, we decided to do some before-and-after testing on a '96 Dodge Ram with a 12-valve Cummins. The vehicle already had a custom-fabricated open exhaust on it with no muffler or catalytic converter. At first glance, that might seem to be the ideal setup for maximizing performance.

This particular system looked like it had been slapped together by a cross-eyed blacksmith. The tubing was of varying sizes, approximately 3 inches in overall diameter at best, and poorly bent with pinches and welded seams that cause turbulence and restrictions. Also, the Y-section did not allow for a smooth transition to the dual rear pipes and displayed several leaks.

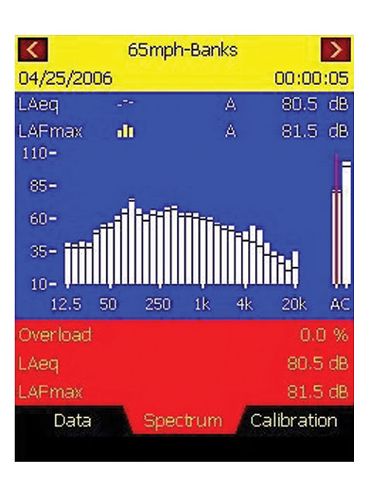

Banks Power took one look at this funky, rusty, old plumbing and felt pity for us, offering to replace it with a smooth, mandrel-bent system measuring 4 inches in diameter and outfitted with the its straight-through Monster Muffler. It's claimed to more than double the flow of the stock muffler (which was absent on this particular truck). Also, the Banks unit features an exclusive expansion chamber that dissipates the irritating midrange drone that can plague other straight-through mufflers (and our open exhaust, for that matter). We were hoping that would be the case, but Banks went the extra mile and backed up its claims with some hard numbers.

At the rear of the system is a Banks seamless Y-pipe along with dual 3 1/2-inch 409 stainless tailpipes that include Banks' weld-on 5x6-inch 304 polished stainless tips. The 3 1/2-inch dual tailpipes open the way for the exhaust to zip through, increasing the flow area 52 percent over a single 4-inch tailpipe, according to Banks.

After checking out both the power output and sound levels, frankly, we were surprised by the results. Not only did the Banks system substantially quiet down the exhaust note, we gained power at the same time!

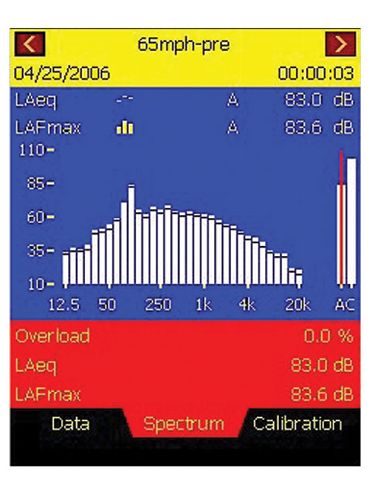

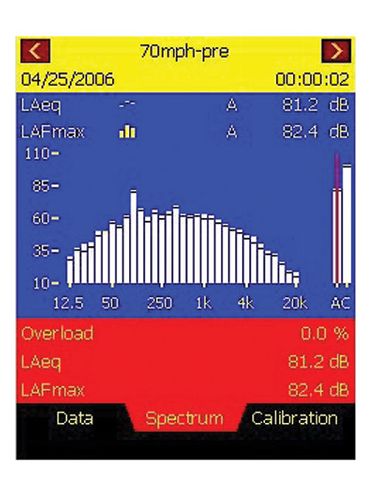

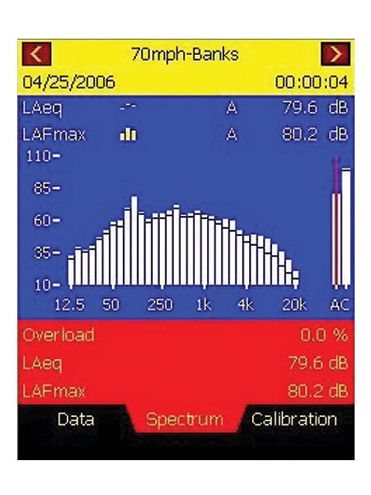

While acceleration and backpressure are fairly simple numbers to measure, analyzing noise levels can get a bit more complicated. That's because sound comes from both the air and vibration (transmitted through solids). Not only that, the location of the driver and the frequency complicate matters. One person's music can be another's annoying noise. What usually matters most to drivers of diesels is how the exhaust sounds in the cabin with the windows rolled up.

In this particular application, the Banks system provided a significant measure of relief, and even gave us a gain in acceleration. The reduction in backpressure also lowered the EGT, as well. All of which is proof positive that it's important to keep an open mind when considering open pipes versus a well-engineered performance exhaust.

Testing the Theory

While we could both feel and hear immediate improvements, it's revealing to review the actual before-and-after numbers. This performance and sound data, gathered by Banks engineer Dain Pankratz, tells the whole story:

*Backpressure as measured at the turbine outlet pipe was virtually eliminated. The biggest gains include a 1.37 psig drop in backpressure, to almost 1/4 psig (that's an 83.5 percent reduction)

*0-60 mph acceleration was improved by 0.4 seconds.

*Exhaust resonation and drone dropped 7 decibels at cruising speeds of 70 mph, for a 66.7 percent improvement! (A drop of 7 decibels is perceived to be twice as quiet).

| 1996 Dodge Ram 12 Valve Cummins testing Exhaust

As much as we might like the sound and the fury of a big, open exhaust on our diesel engines, does it necessarily flow better than a high-performance aftermarket system? Sure, a big, bad diesel rumble announces your arrival with authority. On a long haul, though, that heavy drone from open pipes can drive you batty, not to mention add to driver fatigue. So we wanted to know if it is possible to have a relatively quiet exhaust that still performs well? Or maybe even better?

To get to the bottom of these issues, we decided to do some before-and-after testing on a '96 Dodge Ram with a 12-valve Cummins. The vehicle already had a custom-fabricated open exhaust on it with no muffler or catalytic converter. At first glance, that might seem to be the ideal setup for maximizing performance.

| 1996 Dodge Ram 12 Valve Cummins testing Exhaust

As much as we might like the sound and the fury of a big, open exhaust on our diesel engines, does it necessarily flow better than a high-performance aftermarket system? Sure, a big, bad diesel rumble announces your arrival with authority. On a long haul, though, that heavy drone from open pipes can drive you batty, not to mention add to driver fatigue. So we wanted to know if it is possible to have a relatively quiet exhaust that still performs well? Or maybe even better?

To get to the bottom of these issues, we decided to do some before-and-after testing on a '96 Dodge Ram with a 12-valve Cummins. The vehicle already had a custom-fabricated open exhaust on it with no muffler or catalytic converter. At first glance, that might seem to be the ideal setup for maximizing performance.