| 383 Stroker stroker Sense

The quest to enhance the performance of your vehicle can land you in a never-ending search for effective low-buck modifications. This is especially true for trucks because their owners do more than get groceries or drop children off at school. Many perceived performance upgrades are nothing more than sensory placebos and won't really help when it comes time to get heavy loads up to speed.

Because trucks are used to work as well as play, they usually run through more miles. It's not uncommon for a truck to run through 30,000 miles per year, and some of these miles will be loaded with more than 1 ton additional weight than your generic car, which receives an average of 15,000 miles per year. The hauler's many functions makes it more likely to be re-powered, instead of replaced, when it wears down.

Proven power combinations are the way to get you what you want without attempting to reinvent the wheel. When re-powering your GM small-block, there is no other proven combination better than a stroker motor. The 383 stroker has been around since the '70s and has been perfected over the course of those 30 some-odd years. Although no one seems to know who conceived the idea, many performance parts manufacturers have been making components for the conversion.

A Little HistoryGM made the small-block Chevy in 1955 with the 265ci engine. In 1968, the 350ci engine hit the market and held on strong until 1999. In that 44-year span, there have been many different configurations of the small-block engine. The largest cubic inch production small-block was produced in 1970; it sported 4.125-inch bore with a 3.750-inch stroke, giving the big breather a whopping 400 ci. But due to thin cylinder walls and the problems associated with that, the 350ci engine with a 4.000-inch bore and a 3.480-inch stroke was the most popular for production trucks

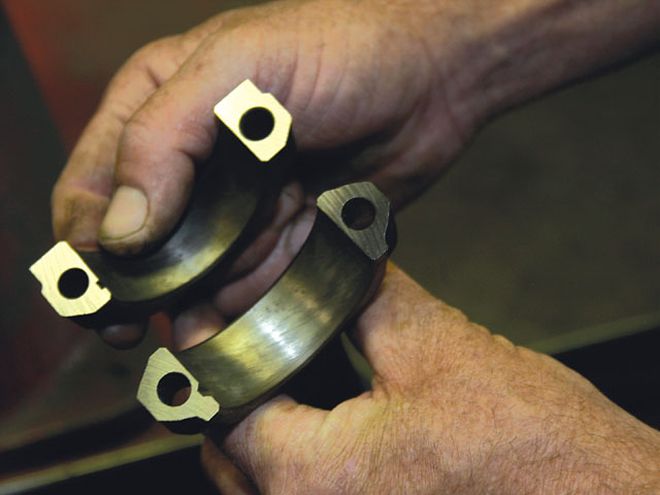

| 383 Stroker federal Mogul

What Are Cubic Inches?The bore diameter area plus the area of the crank stroke multiplied by the number of cylinders equals the amount of volume your engine moves (or displaces) with every revolution. This volume is known as the engine's piston displacement. The calculation for finding the displacement is relatively simple: (pi 4) x bore2 x stroke. For example: As we mentioned above, the Chevy V-8 350ci engine has a 4.000-inch bore, a 3.480-inch stroke, and, of course, eight cylinders. We'll use that as our example.

The first calculation, pi 4, never changes; it simply sets the equation for the geometric shape of a cylinder. Of course, you need to know what pi is - pi =3.1415927. When divided by four, you get 3.1415927 4 = 0.7853981.

The second calculation is to multiply the bore times itself. This gives the top and bottom diameter of the geometric shape. The bore is 4.000, so if multiplied by itself, it would be 4.000 x 4.000 = 16.

The last portion is easy. It's simply the geometric shape x bore x stroke x the number of cylinders: 0.7853981 x 16 x 3.480 x 8 = 349.8. Round the figure off and you have 350 ci.

A 383 stroker has a 0.030 over bore of the stock 350, giving you 4.030 as a bore diameter. Putting the 400 crank in the 350 increases the stroke to 3.750. Other than that, all the other dimensions stay the same. If you do the math, you will get 382.6; round up and you have 383 ci.

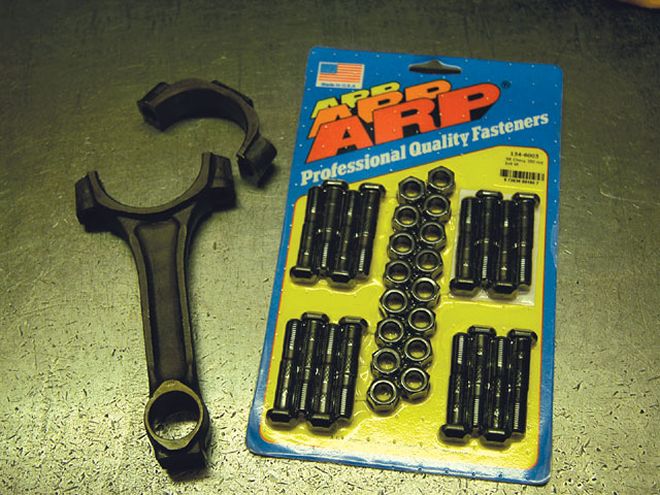

Refurbishing the Rods

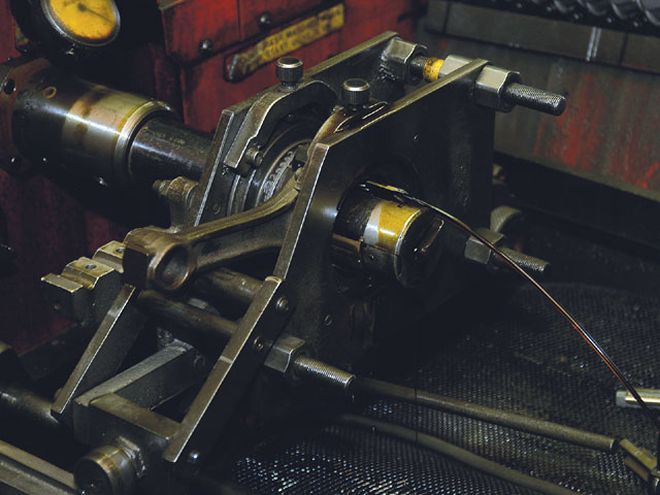

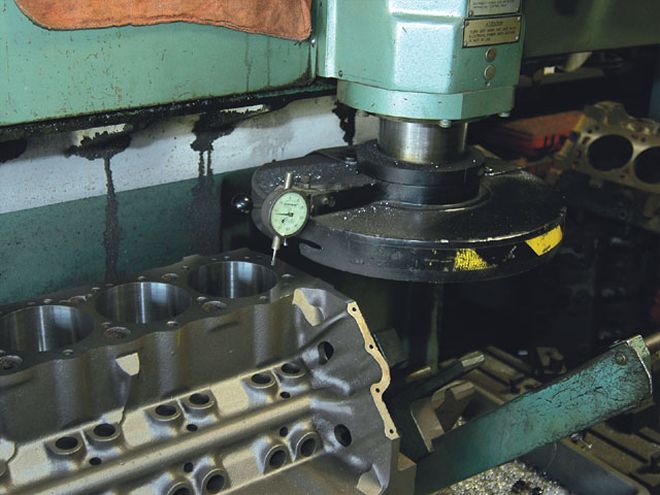

Balancing the Engine

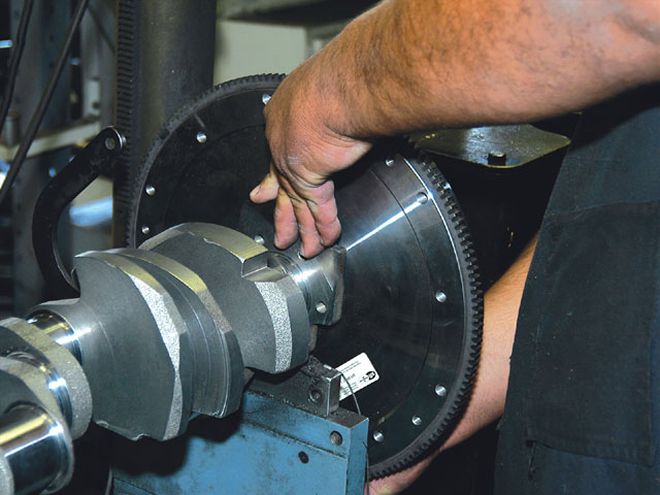

Block Prep

Powerful Upgrades

How A Stroker Works

Basics:More air and fuel equals more power. The phrase "There's no replacement for displacement" comes to mind as far as why it works so well. But if that doesn't curb your appetite for knowledge, then here it is in a little more detail. Increasing the stroke changes some of the characteristics of the engine that render low rpm power. First is that the increased stroke has a larger leverage arm; this allows the fuel combustion to apply more pressure to the flywheel with the same amount of fuel. Second is that there is an increase in cubic inches, which uses more air and fuel, increasing the kinetic energy from the larger combustion. Third is that the longer stroke increases the piston speed, which enhances volumetric efficiency.

Efficiency:The stroker has an increased piston speed because of the longer stroke. The stroke increases the rod main's centerline diameter. The rod and piston have to travel in a larger diameter in the same engine rpm. This increases the piston speed, which makes the stroker pull more air at a lower engine rpm. A 383 has the same piston speed at 2,500 rpm that a 350 has at 3,100 rpm. The increased speed allows the piston to act on the quench area of the combustion chamber at a higher rate of speed, increasing the combustion chamber efficiency. It also allows the engine to come up to maximum efficiency (maximum airflow) faster, which enables the engine to make all its power at a slower rpm. The increased piston speed and long-volume stroke also allows the fuel to stay better atomized due to the change in intake pulses and an increased air speed over the valve.

Performance Upgrades:Performance parts are manufactured to flow more air, rendering more power. The 383 will flow more air with less engine rpm. The larger displacement will make the best use of aftermarket heads, intake manifolds, or any exhaust or induction enhancing components. Even if you're limited to a restricted-smog-emissions fuel-injection system, you will still make more power because of the fact that you will have more cubic inches carrying at least the same power per cubic inch.

Why Do I Want It?:There are very few performance modifications that will actually help the driveability as well as increase engine power. The stroker engine has a lot of low-end grunt, giving your truck more low-end throttle response and more torque to get big loads moving. It's also not uncommon to see an improved mpg from the stroker due to the increased torque.

Where To Get It:We visited Team C Performance in Bellflower, California, where we got the lowdown on the low-buck buildup. Team C Performance has been in business for 25 years. Bud Cornielus and son Mark have worked as a team on the business, as well as on blown hydro boats, since day one. The long performance history has made them no stranger to the 383 stroker motor.

How Much Is It?:Their low-buck do-it-yourself stroker kit comes with the rotating assembly for a mere $499. This includes a cast-iron crank, refurbished 5.700-inch rods, hypereutectic flat-top pistons, a Federal Mogule ring pack, and bearings. If your truck has an automatic tranny, an additional $75 will get you a dampener and flywheel. If your truck has a manual transmission, Team C carries a large line of Centerforce clutch components to chose from. Balancing the components from Team C will run you about $99 to complete the rotating assembly.

Adding more stroke to your engine can increase the compression ratio. There are three different head configurations that will affect the compression of your engine. With a 4.030-inch bore and 3.750-inch stroke, your compression will change accordingly.

58cc combustion chamber - 11.9-1 Compression64cc combustion chamber - 11.1-1 Compression76cc combustion chamber - 9.7-1 Compression

Not to worry; Team C has a huge selection of JE SRP pistons that will accommodate the proper compression ratio for almost any head design. These off-the-shelf forged pistons will increase the price of the build, but they're a major upgrade for any performance engine and well worth the extra dough.

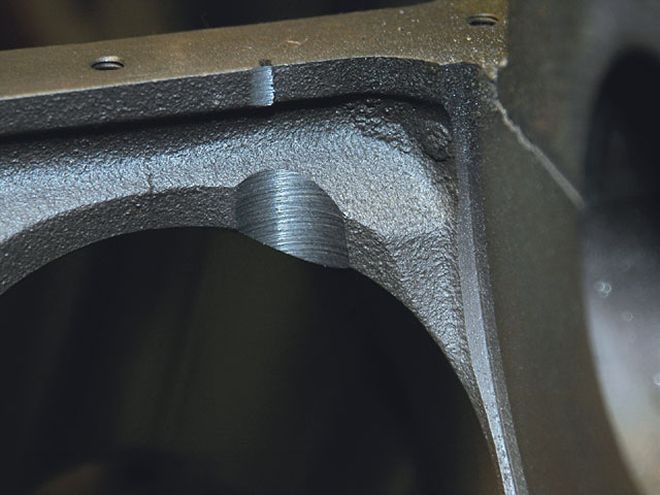

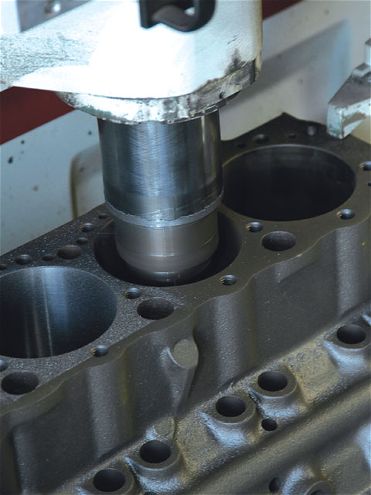

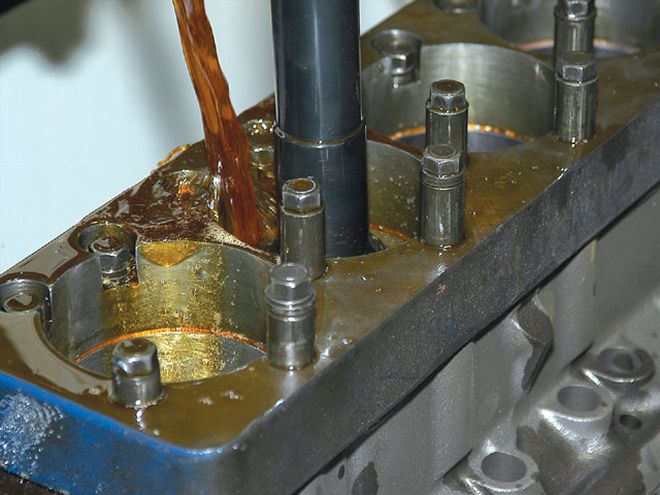

Rebuilding means you will be machining your engine block. Team C not only has a large storefront with tons of goodies, it also has a full-service machine shop out back. There will be an extra step when shoe-horning the 400 crank into the 350 block. Some material will need to be removed from the bottom of the cylinder to make room for proper rod clearance. You could remove the material with a hand-grinder, but you will need the components to mock up the rotating assembly. We were told the minimal clearance is 0.080 inch, but we suggest a 0.100-inch cylinder-to-rod clearance. If your block is already 0.030 over, you may be able to get away with a micro hone. Otherwise, be prepared to pay for a bore job. A complete engine gasket set can be had for about $60. If you assemble the engine yourself, the total would be about $733 plus shipping and tax.

How Much Power Will It Make?Just as with any other engine build, the power output depends on the combination. What we can tell you is that these parts will support as much as 500 hp. If you're rebuilding for power, there is power to be had by just going to a roller-style cam. Team C also caries Comp Cam's variety of roller-hydraulic or mechanical cams that will accommodate any achievable power range and even ECM smog-compliant engines. Although it's hard to predict what your combination will make, here is a list of motors that are dyno-proven.

Keep in mind that if you're in a smog-restricted state, the Air Resources Board will more than likely have a large influence on your engine output. Even with the right cam, the stroker will more than likely pass the sniff test. Also, this conversion is not smog-compliant in some states; consult your local regulations before attempting the conversion.

Horsepower: 325

Torque: 415 lb-ft

Cam (in.): 0.431/0.451, hydraulic roller

Compression: 9.0:1

Induction: Carburetion

Heads: Cast iron

Fuel: 91 octane

Horsepower: 357

Torque: 416 lb-ft

Cam (in.): 0.510/0.510

Compression: 9.5:1

Induction: Injection

Heads: GM Vortec (cast iron)

Fuel: 91 octane

Horsepower: 430

Torque: 430 lb-ft

Cam (in.): 0.525/0.525

Compression: 9.6 to 1

Induction: Carburetion

Heads: GM Fastburn heads

Fuel: 91 octane

Horsepower: 466

Torque: 471 lb-ft

Cam (in.): 0.600/0.610, lift mechanical roller

Compression: 10:75.1

Induction: Carburetion

Heads: GM LT1-type aluminum head (ported)

Fuel: 91 octane

| 383 Stroker stroker Sense

The quest to enhance the performance of your vehicle can land you in a never-ending search for effective low-buck modifications. This is especially true for trucks because their owners do more than get groceries or drop children off at school. Many perceived performance upgrades are nothing more than sensory placebos and won't really help when it comes time to get heavy loads up to speed.

Because trucks are used to work as well as play, they usually run through more miles. It's not uncommon for a truck to run through 30,000 miles per year, and some of these miles will be loaded with more than 1 ton additional weight than your generic car, which receives an average of 15,000 miles per year. The hauler's many functions makes it more likely to be re-powered, instead of replaced, when it wears down.

Proven power combinations are the way to get you what you want without attempting to reinvent the wheel. When re-powering your GM small-block, there is no other proven combination better than a stroker motor. The 383 stroker has been around since the '70s and has been perfected over the course of those 30 some-odd years. Although no one seems to know who conceived the idea, many performance parts manufacturers have been making components for the conversion.

A Little History

| 383 Stroker stroker Sense

The quest to enhance the performance of your vehicle can land you in a never-ending search for effective low-buck modifications. This is especially true for trucks because their owners do more than get groceries or drop children off at school. Many perceived performance upgrades are nothing more than sensory placebos and won't really help when it comes time to get heavy loads up to speed.

Because trucks are used to work as well as play, they usually run through more miles. It's not uncommon for a truck to run through 30,000 miles per year, and some of these miles will be loaded with more than 1 ton additional weight than your generic car, which receives an average of 15,000 miles per year. The hauler's many functions makes it more likely to be re-powered, instead of replaced, when it wears down.

Proven power combinations are the way to get you what you want without attempting to reinvent the wheel. When re-powering your GM small-block, there is no other proven combination better than a stroker motor. The 383 stroker has been around since the '70s and has been perfected over the course of those 30 some-odd years. Although no one seems to know who conceived the idea, many performance parts manufacturers have been making components for the conversion.

A Little History | 383 Stroker federal Mogul

What Are Cubic Inches?

| 383 Stroker federal Mogul

What Are Cubic Inches?