If your engine was directly affixed to a transmission, it would die every time you came to a stop—and that would be a problem. The solution to this issue is a torque converter, a fluid coupling device that is placed between the engine and transmission. A torque converter uses transmission fluid to convert the engine's energy into forward momentum, yet since it's not mechanically connected to the engine, it allows it to idle without moving the vehicle.

The Basics: Well-known Nomenclature

You may have heard terms like "slip percentage," "stall speed," and "lockup" in reference to torque converters but were unsure what they meant, so we're here to explain them. When you're sitting at a stoplight, the engine is spinning, but the vehicle isn't moving at all. At this point, the torque converter is merely churning fluid and allowing the vehicle to sit in place while the engine turns. The slip percentage is the ratio of engine speed vs. road speed, so in the case of a vehicle sitting still, the slip percentage would be 100 percent.

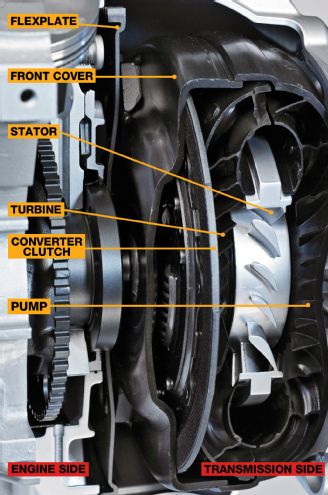

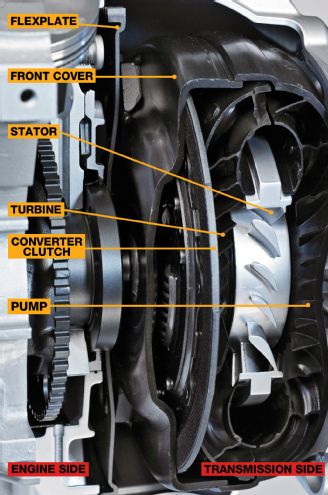

| This cutaway series from the July '07 issue of Diesel Power shows the various parts of the torque converter. Front (engine) to back (transmission), they are the pump and rear cover, the stator, the turbine, the converter clutch, and finally, the front cover.

Now let's say you start feeding the engine some throttle with the brakes held firm. This is known as power-braking, or brake-boosting. While the slip rate will still be 100 percent, more and more of the engine's power will be transmitted to the rear wheels, until a good amount of boost (let's say 15 to 20 psi) can be built. At this point, we've reached the stall speed of the converter, the amount of rpm it will spin without the truck pushing through the brakes or rpm increasing. Converters are commonly built with stall speeds ranging from 1,500 to 2,500 rpm, although 3,000-rpm-or-higher stall converters can be designed specifically for racing applications.

High Stall vs. Low Stall

Factory torque converters utilize around 2,000 to 2,200 rpm stall in most diesels, and they're that way for a reason, as most factory ¾-ton pickup-sized engines spin about 3,000 to 3,500 rpm and can create full boost by about 2,000 rpm. This means that for normal driving and towing situations, the truck can always create full boost, since the stall speed is matched to the factory turbocharger. But when the truck is modified, everything changes. High-stall converters are used exclusively in drag racing, sled pulling, and hot street applications requiring large turbochargers. It's not uncommon to see converters with stall speeds of 3,500 rpm or higher (the redline of a normal engine), as these modified powerplants can spin 5,000 rpm or more, so they still have a usable powerband.

For many street trucks that are used for towing, daily driving, and performance, owners choose a lower-than-stock stall converter. While high-stall converters are the ticket for racing, they generate lots of heat due to high slip percentages and can create a huge rpm drop when lockup is engaged. With a responsive turbo (especially the newer VGT models), a low-stall converter will deliver more power to the rear wheels and create less heat without lockup. A truck towing a trailer through a hilly area where it's impossible to stay in one gear is a perfect example of where a low-stall converter would be ideally suited.

| Most factory converters have small lugs for the converter bolts. Many aftermarket converters, however, use this space for extra clutch discs and a more robust front cover, so the lugs are eliminated and the front of the converter is a smooth, solid piece.

What's "Lockup?"

As rpm increases, the slip rate of a torque converter goes down. In gasoline applications, which may turn 6,000 rpm or more, this means converter slip can be 7 percent or less at high rpm, which means very little power is lost through the drivetrain. In most diesel applications that are limited to 3,000 to 4,000 rpm, the converter slippage can be 20 percent or more, which means quite a bit of power is lost. So, almost all modern diesels equipped with automatics have a clutch that locks against the front of the converter, turning it into one solid piece and transferring all the power to the rear wheels. Unfortunately, as power is increased, this clutch becomes a weak point and can slip. That's why virtually all aftermarket converters have multiple discs to increase clamping area, the most popular being a "triple-disc" converter.

| Sun Coast Converters is a company that has been building diesel transmissions for many years. Shown here are some of the exotic parts and pieces that go into building one of its torque converters.

So Which Converter Should You Buy?

The converter you buy should always match the turbo combination, so trucks with variable-vane turbos, slight turbo upgrades, or small compound turbos should almost always go with a slightly lower than stock stall. For large single turbos, sled pulling or drag racing applications, high-rpm engines, or high-elevation applications, a higher-stall converter is recommended. Before making a final decision, make sure to consult a reputable transmission builder such as ATS or Sun Coast, or a local shop that specializes in diesel transmissions.

"A lockup torque converter reduces slippage to virtually nothing."

| Especially on Dodge transmissions, upgrading things like shafts, flexplates (shown), and other hard parts is essential for reliable performance.

| This cutaway series from the July '07 issue of Diesel Power shows the various parts of the torque converter. Front (engine) to back (transmission), they are the pump and rear cover, the stator, the turbine, the converter clutch, and finally, the front cover.

Now let's say you start feeding the engine some throttle with the brakes held firm. This is known as power-braking, or brake-boosting. While the slip rate will still be 100 percent, more and more of the engine's power will be transmitted to the rear wheels, until a good amount of boost (let's say 15 to 20 psi) can be built. At this point, we've reached the stall speed of the converter, the amount of rpm it will spin without the truck pushing through the brakes or rpm increasing. Converters are commonly built with stall speeds ranging from 1,500 to 2,500 rpm, although 3,000-rpm-or-higher stall converters can be designed specifically for racing applications.

High Stall vs. Low Stall

Factory torque converters utilize around 2,000 to 2,200 rpm stall in most diesels, and they're that way for a reason, as most factory ¾-ton pickup-sized engines spin about 3,000 to 3,500 rpm and can create full boost by about 2,000 rpm. This means that for normal driving and towing situations, the truck can always create full boost, since the stall speed is matched to the factory turbocharger. But when the truck is modified, everything changes. High-stall converters are used exclusively in drag racing, sled pulling, and hot street applications requiring large turbochargers. It's not uncommon to see converters with stall speeds of 3,500 rpm or higher (the redline of a normal engine), as these modified powerplants can spin 5,000 rpm or more, so they still have a usable powerband.

For many street trucks that are used for towing, daily driving, and performance, owners choose a lower-than-stock stall converter. While high-stall converters are the ticket for racing, they generate lots of heat due to high slip percentages and can create a huge rpm drop when lockup is engaged. With a responsive turbo (especially the newer VGT models), a low-stall converter will deliver more power to the rear wheels and create less heat without lockup. A truck towing a trailer through a hilly area where it's impossible to stay in one gear is a perfect example of where a low-stall converter would be ideally suited.

| This cutaway series from the July '07 issue of Diesel Power shows the various parts of the torque converter. Front (engine) to back (transmission), they are the pump and rear cover, the stator, the turbine, the converter clutch, and finally, the front cover.

Now let's say you start feeding the engine some throttle with the brakes held firm. This is known as power-braking, or brake-boosting. While the slip rate will still be 100 percent, more and more of the engine's power will be transmitted to the rear wheels, until a good amount of boost (let's say 15 to 20 psi) can be built. At this point, we've reached the stall speed of the converter, the amount of rpm it will spin without the truck pushing through the brakes or rpm increasing. Converters are commonly built with stall speeds ranging from 1,500 to 2,500 rpm, although 3,000-rpm-or-higher stall converters can be designed specifically for racing applications.

High Stall vs. Low Stall

Factory torque converters utilize around 2,000 to 2,200 rpm stall in most diesels, and they're that way for a reason, as most factory ¾-ton pickup-sized engines spin about 3,000 to 3,500 rpm and can create full boost by about 2,000 rpm. This means that for normal driving and towing situations, the truck can always create full boost, since the stall speed is matched to the factory turbocharger. But when the truck is modified, everything changes. High-stall converters are used exclusively in drag racing, sled pulling, and hot street applications requiring large turbochargers. It's not uncommon to see converters with stall speeds of 3,500 rpm or higher (the redline of a normal engine), as these modified powerplants can spin 5,000 rpm or more, so they still have a usable powerband.

For many street trucks that are used for towing, daily driving, and performance, owners choose a lower-than-stock stall converter. While high-stall converters are the ticket for racing, they generate lots of heat due to high slip percentages and can create a huge rpm drop when lockup is engaged. With a responsive turbo (especially the newer VGT models), a low-stall converter will deliver more power to the rear wheels and create less heat without lockup. A truck towing a trailer through a hilly area where it's impossible to stay in one gear is a perfect example of where a low-stall converter would be ideally suited.

| Most factory converters have small lugs for the converter bolts. Many aftermarket converters, however, use this space for extra clutch discs and a more robust front cover, so the lugs are eliminated and the front of the converter is a smooth, solid piece.

What's "Lockup?"

As rpm increases, the slip rate of a torque converter goes down. In gasoline applications, which may turn 6,000 rpm or more, this means converter slip can be 7 percent or less at high rpm, which means very little power is lost through the drivetrain. In most diesel applications that are limited to 3,000 to 4,000 rpm, the converter slippage can be 20 percent or more, which means quite a bit of power is lost. So, almost all modern diesels equipped with automatics have a clutch that locks against the front of the converter, turning it into one solid piece and transferring all the power to the rear wheels. Unfortunately, as power is increased, this clutch becomes a weak point and can slip. That's why virtually all aftermarket converters have multiple discs to increase clamping area, the most popular being a "triple-disc" converter.

| Most factory converters have small lugs for the converter bolts. Many aftermarket converters, however, use this space for extra clutch discs and a more robust front cover, so the lugs are eliminated and the front of the converter is a smooth, solid piece.

What's "Lockup?"

As rpm increases, the slip rate of a torque converter goes down. In gasoline applications, which may turn 6,000 rpm or more, this means converter slip can be 7 percent or less at high rpm, which means very little power is lost through the drivetrain. In most diesel applications that are limited to 3,000 to 4,000 rpm, the converter slippage can be 20 percent or more, which means quite a bit of power is lost. So, almost all modern diesels equipped with automatics have a clutch that locks against the front of the converter, turning it into one solid piece and transferring all the power to the rear wheels. Unfortunately, as power is increased, this clutch becomes a weak point and can slip. That's why virtually all aftermarket converters have multiple discs to increase clamping area, the most popular being a "triple-disc" converter.

| Sun Coast Converters is a company that has been building diesel transmissions for many years. Shown here are some of the exotic parts and pieces that go into building one of its torque converters.

So Which Converter Should You Buy?

The converter you buy should always match the turbo combination, so trucks with variable-vane turbos, slight turbo upgrades, or small compound turbos should almost always go with a slightly lower than stock stall. For large single turbos, sled pulling or drag racing applications, high-rpm engines, or high-elevation applications, a higher-stall converter is recommended. Before making a final decision, make sure to consult a reputable transmission builder such as ATS or Sun Coast, or a local shop that specializes in diesel transmissions.

| Sun Coast Converters is a company that has been building diesel transmissions for many years. Shown here are some of the exotic parts and pieces that go into building one of its torque converters.

So Which Converter Should You Buy?

The converter you buy should always match the turbo combination, so trucks with variable-vane turbos, slight turbo upgrades, or small compound turbos should almost always go with a slightly lower than stock stall. For large single turbos, sled pulling or drag racing applications, high-rpm engines, or high-elevation applications, a higher-stall converter is recommended. Before making a final decision, make sure to consult a reputable transmission builder such as ATS or Sun Coast, or a local shop that specializes in diesel transmissions.

| Especially on Dodge transmissions, upgrading things like shafts, flexplates (shown), and other hard parts is essential for reliable performance.

| Especially on Dodge transmissions, upgrading things like shafts, flexplates (shown), and other hard parts is essential for reliable performance.