This month’s basic training lesson addresses the diesel engine’s arch nemesis: contaminated fuel. Whether it’s fuel degradation, water, dirt, sand, dust, or even rust, unclean fuel can wreak havoc on the modern diesel’s fuel supply and injection system. Our goal is to show you the different types of contaminants, how they get in your tank, and the maintenance regimen you can implement to prevent them from causing any damage.

| August 2013 Basic Training Contaminated Fuel Dirty Fuel

Causes of Contamination

Ninety-nine percent of all problems originate in your truck’s tank, and organic debris from fuel breakdown and deterioration makes up more than 90 percent of all fuel contaminants. According to a life expectancy of stored Number 2 diesel study conducted by the University of Idaho, 26 percent degradation occurred after just 28 days of storage. Essentially, this means diesel starts to break down as soon as it is produced. In most cases, the fuel filter easily collects inorganic debris, such as dirt, sand, dust, and rust, although finding rust anywhere in the fuel system is cause for concern.

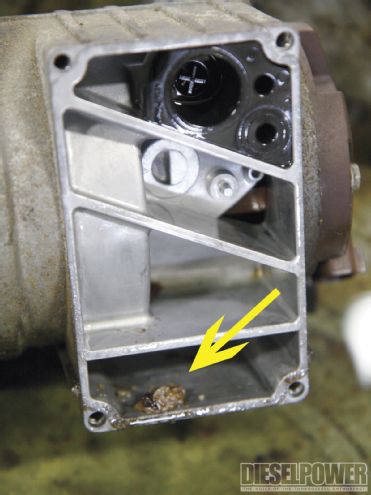

| This ’97 F-350 is a perfect example of what happens when diesels spend a lot of time sitting. It racks up just 1,500 miles annually and is really only used for plowing snow (which is roughly two months out of the year). A combination of neglect, fuel degradation, and steel tank corrosion led to the photo on the first page of this article: rust in the fuel system.

Why Water Forms

Water is arguably the most damaging thing that can infiltrate a diesel’s fuel system, and all it takes is one bad tank to begin the formation of rust, microbes, and other debris that can damage your injection system. Unfortunately, diesel is attracted to water (at the molecular level)—and even absorbs it. In addition, most fueling stations today dispense fuel that contains a biodiesel blend, and biodiesel has an even higher affinity for water. Because of this, water will always be an inherent issue, which is why all diesel engines come with water separators as standard equipment.

Water makes it into your tank either by being pumped in, or due to condensation forming within the tank. Condensation is more prevalent in humid climates. The two forms of water that can exist in diesel are dissolved and free. Dissolved water is most common, and is easily dealt with at the water separator. However, free water (what drops out of a suspended state) is problematic. Its presence allows microbiological growth to rapidly occur, where slimy and sludge-like substances (often referred to as algae) can form, clogging fuel filters and causing corrosion of metal surfaces (steel tanks, pickup tubes, and fuel lines, most notably).

Tips To Live By

While we can’t control the stability and cleanliness of the fuel we buy from the pump, we can adhere to a strict preventative maintenance regimen to keep us out of harm’s way. First, fill up at high-volume, high-traffic stations like truck stops, where fuel doesn’t have a chance to sit and degrade. Second, treat the fuel you buy with an alcohol-free, water-dispersing additive. Third, always replace your fuel filter(s) at or before the recommended change interval. Fourth, drain your water separator (where applicable) monthly. Finally, if you plan to store your truck or bulk fuel for an extended period of time, always top off the tank.

| If you do plan to store diesel or let your truck sit for an extended amount of time, we highly recommend some sort of fuel stabilizer. Gold Eagle’s STA-BIL diesel formula performs all the jobs you need it to. It resists degradation and sediment formation, reduces oxidation, provides thermal stability, removes water, adds lubricity, and features detergents that help clean the entire fuel system. STA-BIL is said to be effective for up to 12 months, and many RV and boat owners, who park their respective machines for the better part of the year, swear by it.