| diesel Fuel Injectors diesel Injector

Diesel injectors have gotten increasingly complex over the last twenty years of diesel development, but their basic design is fairly simple. Diesel fuel from the injection pump enters the mechanical injector body and starts to build pressure. Once the pressure is high enough (about 4,000 psi), a check valve in the injector is lifted off its seat, and fuel sprays through. Any excess fuel that remains after the valve is opened is then returned back out through the injector body, then back to the injection pump.

Ford Takes A Different RouteIn 1994, Ford changed the engines in its F-series from indirect-injection, to a direct-injection HEUI system. HEUI stands for hydraulic electronic unit injection and uses engine oil as an actuator for the injector. The engine oil is used to boost fuel pressure inside the injector, so if you have a 7.3L or 6.0L Power Stroke, make sure your engine is full of oil-and change it often-it's what's helping fuel your truck.

Common-Rail SystemsIn 2001, General Motors introduced a new line of diesel pickups, which featured a Bosch common-rail injection system. While common-rail injection isn't a new idea, it has helped modern diesels become quieter, more efficient, and more emissions-friendly. In 2002, Dodge jumped on the common-rail bandwagon, as did Ford in 2007. Common-rail injectors are much more complex than their earlier counterparts because they use a solenoid and two pressure chambers to create an injection event. The solenoid is triggered by the vehicle's computer, which is used to vary injection timing and fire multiple injection events. Many of the newest diesels on the market use super-fast injectors controlled by piezoelectricity, called piezo injectors for short. They use crystals and electricity as an actuator and can fire up to five injection events per power stroke, which helps reduce emissions and quiet the engine.

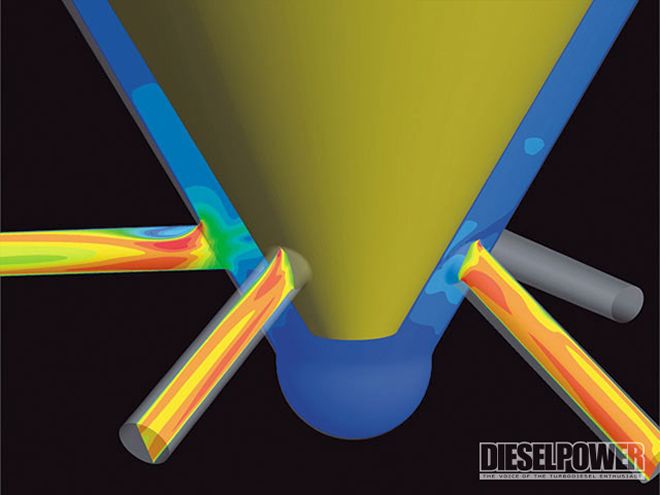

Modifying InjectorsAt the very tip of the injector is the injector nozzle, which is the part that is most commonly modified when you purchase aftermarket injectors. New nozzles are fitted to the old injector bodies, usually resulting in horsepower gains from larger or additional injector holes. As long as the injection pump and turbocharger can keep up, having larger injectors will flow more fuel into the engine, and produce more power. When a custom set of injectors is ordered, each injector is referred to by the number of holes multiplied by the hole size. Therefore, 5x13 injectors would have five holes at thirteen-thousands of an inch. In the case of very large injectors, internal modifications can be present as well, which is why price usually goes up for the higher-horsepower models.

If A Picture Is Worth A Thousand Words...Then a video has to be worth even more! While we were surfing the net, we came across this cool video of how a common-rail injector works. We can't take any credit for making it, but whoever made the video did an excellent job. It covers how an injector functions and even shows a slow-motion animation of pilot, main, and post injections inside the cylinder bore. Check it out at http://www.youtube.com/watch?v=aGwV9ueHcz4.

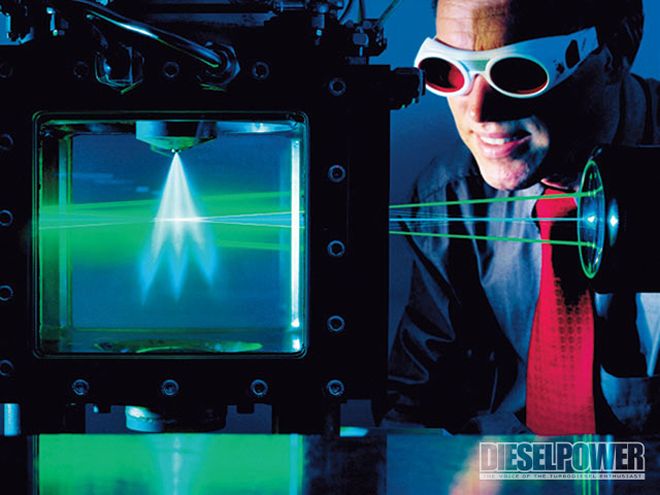

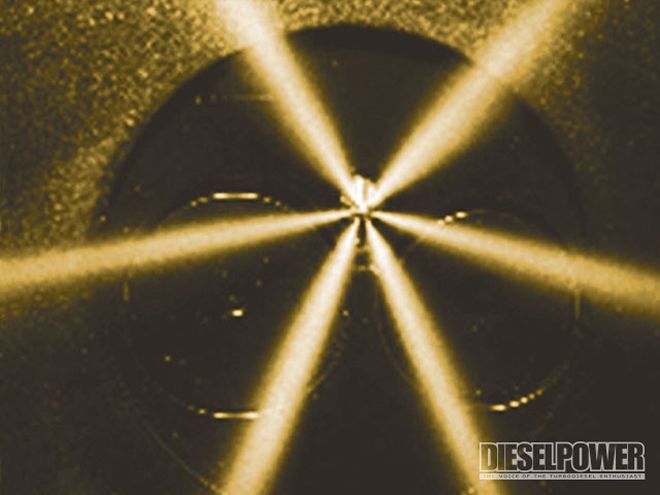

What Is Injector Chatter?It's a common belief that diesel injectors simply spray fuel onto the piston like a garden hose. Actually, this is not the case, and the truth is far more interesting. When operating properly, diesel injectors will chatter (an oscillation of the pressure spring) and fuel will be pulsed onto the piston at a rate of 2,000 to 3,000 times per second, which greatly improves atomization. While injection events only last a fraction of a second, this means that the average injector will chatter at least a few hundred times during every injection event. Think about that the next time you're driving down the road.

DP

| diesel Fuel Injectors diesel Injector

Diesel injectors have gotten increasingly complex over the last twenty years of diesel development, but their basic design is fairly simple. Diesel fuel from the injection pump enters the mechanical injector body and starts to build pressure. Once the pressure is high enough (about 4,000 psi), a check valve in the injector is lifted off its seat, and fuel sprays through. Any excess fuel that remains after the valve is opened is then returned back out through the injector body, then back to the injection pump.

Ford Takes A Different Route

| diesel Fuel Injectors diesel Injector

Diesel injectors have gotten increasingly complex over the last twenty years of diesel development, but their basic design is fairly simple. Diesel fuel from the injection pump enters the mechanical injector body and starts to build pressure. Once the pressure is high enough (about 4,000 psi), a check valve in the injector is lifted off its seat, and fuel sprays through. Any excess fuel that remains after the valve is opened is then returned back out through the injector body, then back to the injection pump.

Ford Takes A Different Route