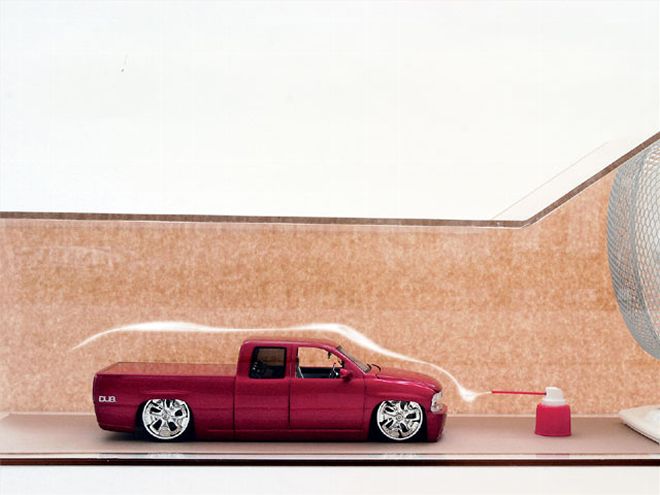

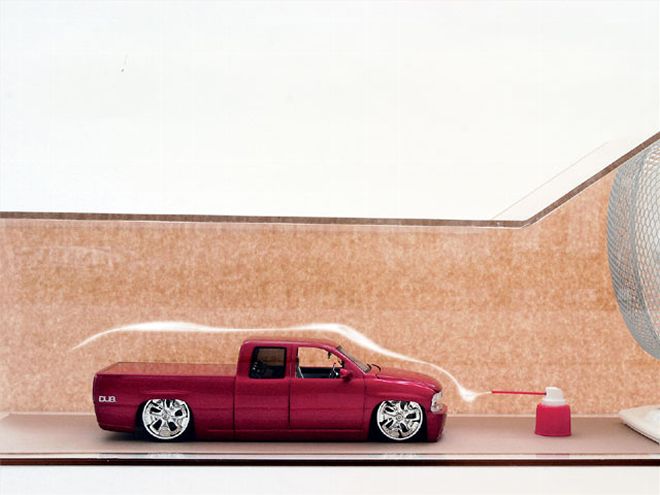

| This homebuilt plexiglass desk fan wind tunnel simulates the airflow as it travels over both the Chevrolet Silverado and GMC Yukon Denali profiles.

Ok we know the aerodynamics of a truck and SUV is like floating a brick upstream. Designing a sleeker-coefficient aero package is every truck manufactures objective with every up-coming model year. After design engineers and technicians have spent hours and hours plotting a multitude of different rendering flavors with an assortment of new tastes, it is not until the artists' sketches become clay model and are actually tested in a wind tunnel to evaluate it's sleek ability as it penetrates through the atmosphere.

When studying aerodynamics we are trying to capture the scientific amenities and characteristics of a moving object as penetrates the earths atmosphere while traveling on the ground.

The basics of aerodynamics are air pressure and how it flows around a moving object, or how the object moves through the air. There are four, major contributors to the effects of aerodynamics of a moving object: drag, down force, lift, and yaw.

Aerodynamic Terminology Drag: Is resistance caused by penetrating the atmosphere with a truck's leading edge creating turbulent airflow over, under, and around a smooth surface area (i.e., a truck's leading edge, grille, front bumper, fenders, hood, cab, bed, tailgate, and rear bumper). Another way to describe drag is, a result of skin friction. Longer truck beds can create a lower drag coefficient.

Down Force: Is the ability of a forward moving truck to create a downward pressure on the topside of its outer skin. Starting with its leading edge the front bumper lip, hood, A-pillar/windshield, cab/SUV roof, and tonneau cover. As the angle of the surface is tilted at the rear, downward pressure is increased. Increasing the down force will increase the load on the tires' contact patches with the road surface without adding weight to the truck. Developing weight to the tires increases the tires adhesion during high-speed acceleration and cornering, improving the suspension-handling performance.

Lift: Affects the trucks handling in the opposite of "down force" at higher speeds. As air travels underneath the trucks chassis and suspension components it causes turbulence. This rough airflow also contributes to creating lift. When the ground clearance is limited (lowered truck) the airflow is limited causing a positive lift. When the ground clearance is greater (lifted truck) the airflow under the truck is increased. On the other hand a lowered truck limits airflow from getting underneath the truck causing negative lift pressure.

Yaw: Yaw is defined as the aerodynamic side load, or pressure effected onto the side panels of the truck: fenders, doors, windows, cab, and bedsides. Yaw or crosswinds tend to create increased pressure causing the truck to yaw in the direction of the crosswind. As the forward speed is increased, it equalizes the yaw wind speed, which causes the forward and yaw speeds to equalize

Ride Height: When a truck is shipped from the manufacture to the dealership its ride height is set to DOT regulations. But after a customer drives his or her newly purchased truck or SUV of the lot they may do what they wish with it ride height. Some lift them to the sky and others drop them to the ground. What is the best ride height for a truck or SUV?

Wind tunnel testing has proved that the lower the vehicle the better its coefficient drag becomes, due to the fact that less air is able to flow underneath the chassis create drag. Elevated trucks and SUV's we see cruising the boulevards or prowling rugged terrain are a mess when it comes to creating a coefficient aero package. The greater the truck or SUV's ride height,the more drag and turbulence it's creating underneath the chassis. Other contributors are the massive wheels/tires that are part of the rugged off-road image. As these redundant rolling spools of aluminum RPMs increase, more turbulence is developed causing incredible drag load. Less air travels underneath causing turbulence.

Leading Edge: The leading edge is the frontal surface area that is first to penetrate the atmosphere. The perfect leading edge some say is a small area like an arrow, wedge shape. Others say its just the opposite a leading edge of a blunt nose and tapered rear, reversed wedge shape.

Pointed Arrow Shape: The small piercing front leading edge penetrates the atmosphere but as the shape passes through the initial hole in the atmosphere, drag is increased due to the increased objects shape, causing friction and drag the further the vehicle passes through the atmosphere.

Blunt Nose With Tapered Tail: As the larger, blunt-nose leading edge penetrates the atmosphere, it makes a greater initial hole in the atmosphere compared to its trailing edge. By creating a larger hole for the tapered remaining shape to pass through, causing less surface friction and drag.

Ways To Improve Coefficient Drag (Cd):*Round the edges of the front end*Tune the grille and fascia openings*Tune the wheel openings*Place spats (small spoilers) in front of the tire opening to reduce turbulence*Tune the size and shapes of the outside mirrors and their attachment arms*Reshape the water channel on the A-pillars*Adjust the front fascia and air dam to reduce drag and turbulence under the vehicle*Tune the bedside height length, increase the radius of the bed rails*Install a tonneau cover with rear spoiler*Tuck up the exhaust system*Use a diffuser to tune the airflow coming off the underside*If at all possible install a "belly pan," underbody panels to cover underneath the chassis and suspension components to smooth the undercarriage airflow*Active air dams that lower at increased speeds*Active rear spoilers that rise at increased speeds, reducing lift and creating down-force*Active ride height that lowers the truck when speed is increased eliminating under-chassis airflow and turbulence-increasing drag

By installing a (soft or hard) tonneau cover will provide less drag reduction of 2 to 7 percent, depending on the cab style, bed length, and overall truck Cd. The average fuel economy improvement ranges from 0.1 to 0.3 mpg.

As the leading edge of the trucks hood and bumper begin to split the air molecules and penetrate the atmosphere, the air flows over, under, and around the truck's/SUV's surfaces causing friction, which creates drag. The air steam will flow faster over the smooth topside of the truck causing a thin boundary layer. Due to surfaces transitional change the airflow velocity is effected, creating a Laminar bubble.

An example of this phenomenon is when the airflow passes over the roofline of the cab. Right behind the cab is a low-pressure area. As the airflow passing over the cab dissipates a bubble is formed in the bed area. A demonstration of this would be if you've ever followed a truck with some trash blowing around in the bed and occasionally rise as if it were going to blow out of the bed, but somehow it is just suspended above the bed rails and swirls around and around then drops back into the bed and floats up the surface and swirls around some more but never blows out of the bed. This is called the Laminar bubble. Due to the chassis, suspension components, and rotating wheels/tires, these restriction factors, cause turbulent flow slowing down the airflow speed.

As the airflow travels over the smooth topside skin of the truck it forms a "boundary layer" between the skin surface and atmospheric pressure.

It seems to be an endless challenge for the OEMs and aftermarket manufactures to design and develop sleek aero shapes to improve the truck's and SUV's coefficient drag contributing to their overall aerodynamic package. Make a brick accelerate straight as an arrow.

| This homebuilt plexiglass desk fan wind tunnel simulates the airflow as it travels over both the Chevrolet Silverado and GMC Yukon Denali profiles.

Ok we know the aerodynamics of a truck and SUV is like floating a brick upstream. Designing a sleeker-coefficient aero package is every truck manufactures objective with every up-coming model year. After design engineers and technicians have spent hours and hours plotting a multitude of different rendering flavors with an assortment of new tastes, it is not until the artists' sketches become clay model and are actually tested in a wind tunnel to evaluate it's sleek ability as it penetrates through the atmosphere.

When studying aerodynamics we are trying to capture the scientific amenities and characteristics of a moving object as penetrates the earths atmosphere while traveling on the ground.

The basics of aerodynamics are air pressure and how it flows around a moving object, or how the object moves through the air. There are four, major contributors to the effects of aerodynamics of a moving object: drag, down force, lift, and yaw.

Aerodynamic Terminology Drag: Is resistance caused by penetrating the atmosphere with a truck's leading edge creating turbulent airflow over, under, and around a smooth surface area (i.e., a truck's leading edge, grille, front bumper, fenders, hood, cab, bed, tailgate, and rear bumper). Another way to describe drag is, a result of skin friction. Longer truck beds can create a lower drag coefficient.

Down Force: Is the ability of a forward moving truck to create a downward pressure on the topside of its outer skin. Starting with its leading edge the front bumper lip, hood, A-pillar/windshield, cab/SUV roof, and tonneau cover. As the angle of the surface is tilted at the rear, downward pressure is increased. Increasing the down force will increase the load on the tires' contact patches with the road surface without adding weight to the truck. Developing weight to the tires increases the tires adhesion during high-speed acceleration and cornering, improving the suspension-handling performance.

Lift: Affects the trucks handling in the opposite of "down force" at higher speeds. As air travels underneath the trucks chassis and suspension components it causes turbulence. This rough airflow also contributes to creating lift. When the ground clearance is limited (lowered truck) the airflow is limited causing a positive lift. When the ground clearance is greater (lifted truck) the airflow under the truck is increased. On the other hand a lowered truck limits airflow from getting underneath the truck causing negative lift pressure.

Yaw: Yaw is defined as the aerodynamic side load, or pressure effected onto the side panels of the truck: fenders, doors, windows, cab, and bedsides. Yaw or crosswinds tend to create increased pressure causing the truck to yaw in the direction of the crosswind. As the forward speed is increased, it equalizes the yaw wind speed, which causes the forward and yaw speeds to equalize

Ride Height: When a truck is shipped from the manufacture to the dealership its ride height is set to DOT regulations. But after a customer drives his or her newly purchased truck or SUV of the lot they may do what they wish with it ride height. Some lift them to the sky and others drop them to the ground. What is the best ride height for a truck or SUV?

Wind tunnel testing has proved that the lower the vehicle the better its coefficient drag becomes, due to the fact that less air is able to flow underneath the chassis create drag. Elevated trucks and SUV's we see cruising the boulevards or prowling rugged terrain are a mess when it comes to creating a coefficient aero package. The greater the truck or SUV's ride height,the more drag and turbulence it's creating underneath the chassis. Other contributors are the massive wheels/tires that are part of the rugged off-road image. As these redundant rolling spools of aluminum RPMs increase, more turbulence is developed causing incredible drag load. Less air travels underneath causing turbulence.

Leading Edge: The leading edge is the frontal surface area that is first to penetrate the atmosphere. The perfect leading edge some say is a small area like an arrow, wedge shape. Others say its just the opposite a leading edge of a blunt nose and tapered rear, reversed wedge shape.

Pointed Arrow Shape: The small piercing front leading edge penetrates the atmosphere but as the shape passes through the initial hole in the atmosphere, drag is increased due to the increased objects shape, causing friction and drag the further the vehicle passes through the atmosphere.

Blunt Nose With Tapered Tail: As the larger, blunt-nose leading edge penetrates the atmosphere, it makes a greater initial hole in the atmosphere compared to its trailing edge. By creating a larger hole for the tapered remaining shape to pass through, causing less surface friction and drag.

Ways To Improve Coefficient Drag (Cd):*Round the edges of the front end*Tune the grille and fascia openings*Tune the wheel openings*Place spats (small spoilers) in front of the tire opening to reduce turbulence*Tune the size and shapes of the outside mirrors and their attachment arms*Reshape the water channel on the A-pillars*Adjust the front fascia and air dam to reduce drag and turbulence under the vehicle*Tune the bedside height length, increase the radius of the bed rails*Install a tonneau cover with rear spoiler*Tuck up the exhaust system*Use a diffuser to tune the airflow coming off the underside*If at all possible install a "belly pan," underbody panels to cover underneath the chassis and suspension components to smooth the undercarriage airflow*Active air dams that lower at increased speeds*Active rear spoilers that rise at increased speeds, reducing lift and creating down-force*Active ride height that lowers the truck when speed is increased eliminating under-chassis airflow and turbulence-increasing drag

By installing a (soft or hard) tonneau cover will provide less drag reduction of 2 to 7 percent, depending on the cab style, bed length, and overall truck Cd. The average fuel economy improvement ranges from 0.1 to 0.3 mpg.

As the leading edge of the trucks hood and bumper begin to split the air molecules and penetrate the atmosphere, the air flows over, under, and around the truck's/SUV's surfaces causing friction, which creates drag. The air steam will flow faster over the smooth topside of the truck causing a thin boundary layer. Due to surfaces transitional change the airflow velocity is effected, creating a Laminar bubble.

An example of this phenomenon is when the airflow passes over the roofline of the cab. Right behind the cab is a low-pressure area. As the airflow passing over the cab dissipates a bubble is formed in the bed area. A demonstration of this would be if you've ever followed a truck with some trash blowing around in the bed and occasionally rise as if it were going to blow out of the bed, but somehow it is just suspended above the bed rails and swirls around and around then drops back into the bed and floats up the surface and swirls around some more but never blows out of the bed. This is called the Laminar bubble. Due to the chassis, suspension components, and rotating wheels/tires, these restriction factors, cause turbulent flow slowing down the airflow speed.

As the airflow travels over the smooth topside skin of the truck it forms a "boundary layer" between the skin surface and atmospheric pressure.

It seems to be an endless challenge for the OEMs and aftermarket manufactures to design and develop sleek aero shapes to improve the truck's and SUV's coefficient drag contributing to their overall aerodynamic package. Make a brick accelerate straight as an arrow.

| This homebuilt plexiglass desk fan wind tunnel simulates the airflow as it travels over both the Chevrolet Silverado and GMC Yukon Denali profiles.

Ok we know the aerodynamics of a truck and SUV is like floating a brick upstream. Designing a sleeker-coefficient aero package is every truck manufactures objective with every up-coming model year. After design engineers and technicians have spent hours and hours plotting a multitude of different rendering flavors with an assortment of new tastes, it is not until the artists' sketches become clay model and are actually tested in a wind tunnel to evaluate it's sleek ability as it penetrates through the atmosphere.

When studying aerodynamics we are trying to capture the scientific amenities and characteristics of a moving object as penetrates the earths atmosphere while traveling on the ground.

The basics of aerodynamics are air pressure and how it flows around a moving object, or how the object moves through the air. There are four, major contributors to the effects of aerodynamics of a moving object: drag, down force, lift, and yaw.

Aerodynamic Terminology Drag: Is resistance caused by penetrating the atmosphere with a truck's leading edge creating turbulent airflow over, under, and around a smooth surface area (i.e., a truck's leading edge, grille, front bumper, fenders, hood, cab, bed, tailgate, and rear bumper). Another way to describe drag is, a result of skin friction. Longer truck beds can create a lower drag coefficient.

Down Force: Is the ability of a forward moving truck to create a downward pressure on the topside of its outer skin. Starting with its leading edge the front bumper lip, hood, A-pillar/windshield, cab/SUV roof, and tonneau cover. As the angle of the surface is tilted at the rear, downward pressure is increased. Increasing the down force will increase the load on the tires' contact patches with the road surface without adding weight to the truck. Developing weight to the tires increases the tires adhesion during high-speed acceleration and cornering, improving the suspension-handling performance.

Lift: Affects the trucks handling in the opposite of "down force" at higher speeds. As air travels underneath the trucks chassis and suspension components it causes turbulence. This rough airflow also contributes to creating lift. When the ground clearance is limited (lowered truck) the airflow is limited causing a positive lift. When the ground clearance is greater (lifted truck) the airflow under the truck is increased. On the other hand a lowered truck limits airflow from getting underneath the truck causing negative lift pressure.

Yaw: Yaw is defined as the aerodynamic side load, or pressure effected onto the side panels of the truck: fenders, doors, windows, cab, and bedsides. Yaw or crosswinds tend to create increased pressure causing the truck to yaw in the direction of the crosswind. As the forward speed is increased, it equalizes the yaw wind speed, which causes the forward and yaw speeds to equalize

Ride Height: When a truck is shipped from the manufacture to the dealership its ride height is set to DOT regulations. But after a customer drives his or her newly purchased truck or SUV of the lot they may do what they wish with it ride height. Some lift them to the sky and others drop them to the ground. What is the best ride height for a truck or SUV?

Wind tunnel testing has proved that the lower the vehicle the better its coefficient drag becomes, due to the fact that less air is able to flow underneath the chassis create drag. Elevated trucks and SUV's we see cruising the boulevards or prowling rugged terrain are a mess when it comes to creating a coefficient aero package. The greater the truck or SUV's ride height,the more drag and turbulence it's creating underneath the chassis. Other contributors are the massive wheels/tires that are part of the rugged off-road image. As these redundant rolling spools of aluminum RPMs increase, more turbulence is developed causing incredible drag load. Less air travels underneath causing turbulence.

Leading Edge: The leading edge is the frontal surface area that is first to penetrate the atmosphere. The perfect leading edge some say is a small area like an arrow, wedge shape. Others say its just the opposite a leading edge of a blunt nose and tapered rear, reversed wedge shape.

Pointed Arrow Shape: The small piercing front leading edge penetrates the atmosphere but as the shape passes through the initial hole in the atmosphere, drag is increased due to the increased objects shape, causing friction and drag the further the vehicle passes through the atmosphere.

Blunt Nose With Tapered Tail: As the larger, blunt-nose leading edge penetrates the atmosphere, it makes a greater initial hole in the atmosphere compared to its trailing edge. By creating a larger hole for the tapered remaining shape to pass through, causing less surface friction and drag.

Ways To Improve Coefficient Drag (Cd):*Round the edges of the front end*Tune the grille and fascia openings*Tune the wheel openings*Place spats (small spoilers) in front of the tire opening to reduce turbulence*Tune the size and shapes of the outside mirrors and their attachment arms*Reshape the water channel on the A-pillars*Adjust the front fascia and air dam to reduce drag and turbulence under the vehicle*Tune the bedside height length, increase the radius of the bed rails*Install a tonneau cover with rear spoiler*Tuck up the exhaust system*Use a diffuser to tune the airflow coming off the underside*If at all possible install a "belly pan," underbody panels to cover underneath the chassis and suspension components to smooth the undercarriage airflow*Active air dams that lower at increased speeds*Active rear spoilers that rise at increased speeds, reducing lift and creating down-force*Active ride height that lowers the truck when speed is increased eliminating under-chassis airflow and turbulence-increasing drag

By installing a (soft or hard) tonneau cover will provide less drag reduction of 2 to 7 percent, depending on the cab style, bed length, and overall truck Cd. The average fuel economy improvement ranges from 0.1 to 0.3 mpg.

As the leading edge of the trucks hood and bumper begin to split the air molecules and penetrate the atmosphere, the air flows over, under, and around the truck's/SUV's surfaces causing friction, which creates drag. The air steam will flow faster over the smooth topside of the truck causing a thin boundary layer. Due to surfaces transitional change the airflow velocity is effected, creating a Laminar bubble.

An example of this phenomenon is when the airflow passes over the roofline of the cab. Right behind the cab is a low-pressure area. As the airflow passing over the cab dissipates a bubble is formed in the bed area. A demonstration of this would be if you've ever followed a truck with some trash blowing around in the bed and occasionally rise as if it were going to blow out of the bed, but somehow it is just suspended above the bed rails and swirls around and around then drops back into the bed and floats up the surface and swirls around some more but never blows out of the bed. This is called the Laminar bubble. Due to the chassis, suspension components, and rotating wheels/tires, these restriction factors, cause turbulent flow slowing down the airflow speed.

As the airflow travels over the smooth topside skin of the truck it forms a "boundary layer" between the skin surface and atmospheric pressure.

It seems to be an endless challenge for the OEMs and aftermarket manufactures to design and develop sleek aero shapes to improve the truck's and SUV's coefficient drag contributing to their overall aerodynamic package. Make a brick accelerate straight as an arrow.