For Part 9 of this series, we've reached a tipping point with our 6.0L Power Stroke project. In an effort to push the 2003 Ford F-250 Super Duty past the 538hp number we made last time (January '14), we upsized to a set of Elite Diesel Engineering's 205cc Tow Power Plus injectors and headed back to the SuperFlow dyno at Randall's Performance. However, with the larger injectors in the mix, we quickly found the limit of the stock 5R110 TorqShift, as it began to slip while on the rollers. Even though the slipping is minimal, we'll need a built automatic before we take it any further.

On a positive note, we've learned that the cutoff point for a stock '03 to '07 5R110 is roughly 550 hp—or at the very least, you're living on borrowed time at this power level. Another good sign was that, after some data logging, the billet-aluminum (stock output) high-pressure oil pump from DieselSite had no problem maintaining injection control pressure (ICP), despite running the 205cc injectors. Read on to see the injector install, a few miscellaneous accessories make their way onto the truck, and this month's dyno results. Also, stand by for an inevitable transmission build in the months ahead.

| 2003 Ford F 250 Super Duty 01 Elite Diesel Engineerings 205cc Tow Power Plus Injectors

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 03

Before installing the 205s, we coated the injector O-rings with petroleum jelly. This simply eases the process of getting the injectors into their respective bores in the heads.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 02

Elite Diesel Engineering's 205cc Stage 2+ injectors are a step bigger than the 185cc Stage 2 units we made 538 hp with in Part 8 (January '14). They utilize eight-hole, 80-percent-larger-than-stock nozzles, which makes them 205/80s. They retail for $3,400. Elite also offers a Stage 2+ DIY injector kit for the do-it-yourselfer. It retails for $1,649.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 04

Once each new injector was in, the injector hold-downs were torqued to the recommended 24 ft-lb spec from Ford.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 05

From there, the log-style oil rails ('03 engines) were installed on each bank, followed by the valve covers. Then the truck was fired up for the first time.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 07

Changing the look of the truck a bit, we also added a set of Bushwacker 2-inch pocket-style flares this month. 4Wheel Parts got the call on this one, while Knoles Performance Solutions took care of the paint matching.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 06

We finally got a set of traction bars on Project Outcast to help keep the rear 10.5 still during hard launches and spirited street driving. The Pro Comp ladder bars were also purchased through our friends at 4Wheel Parts and will definitely improve our 60-foot times at the track. It was nice to see the rear end settled down on the dyno, too.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 08

Even with the 205cc injectors in the mix, the 64mm Powermax-SSX (installed in Part 8) is performing flawlessly. With the bigger injectors, it's even more responsive, keeps EGT very reasonable, and provides awesome driveability. It made 42 psi of boost on the dyno and makes a little more than that on the street.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 09

Not sure how much more the stock TorqShift transmission would be able to handle, we made the trip to the dyno at Randall's Performance and hoped for the best. Unfortunately, our luck ran out this time. Shortly after the 35 percent load was applied to the truck (with the torque converter locked, and in Fourth gear), dyno operator Brian Randall sensed what felt like torque converter slippage.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 10

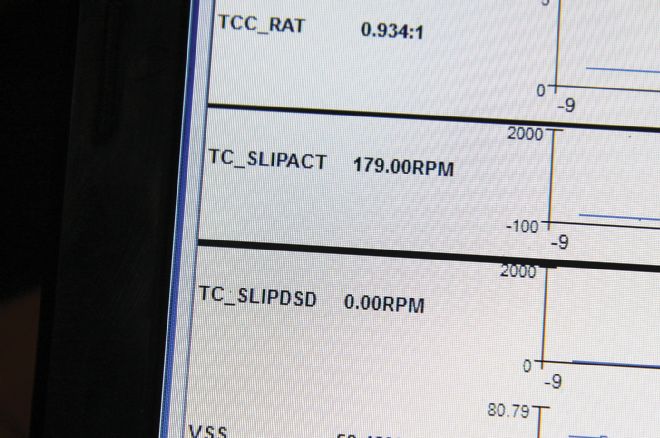

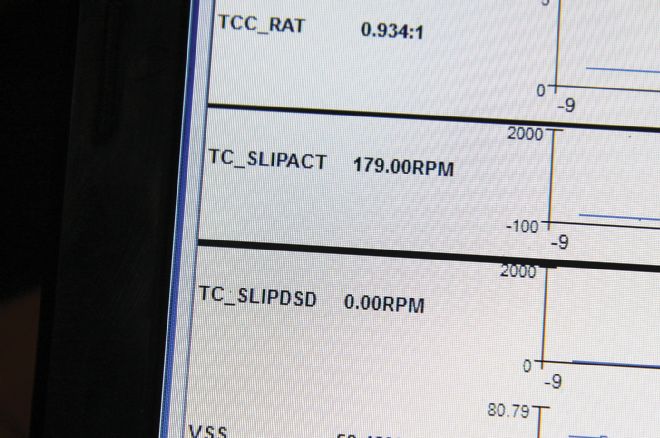

To find out how bad the converter was slipping, the guys at Randall's connected to the truck's OBD-II port and used Ford's IDS (integrated diagnostic system) to log a run. The number circled here shows the transmission's input shaft is turning 179 rpm less than the engine, indicating torque converter slip.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 11

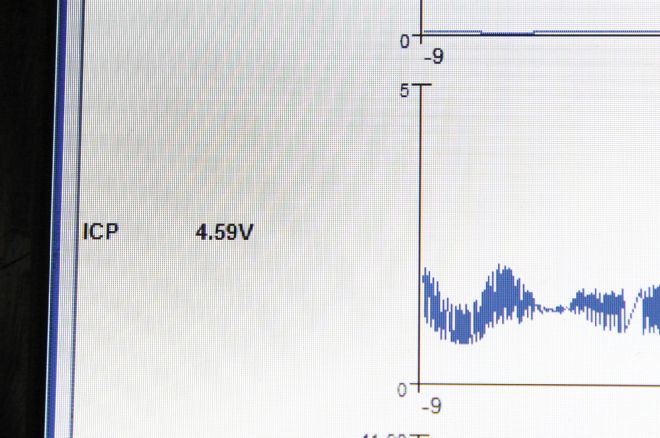

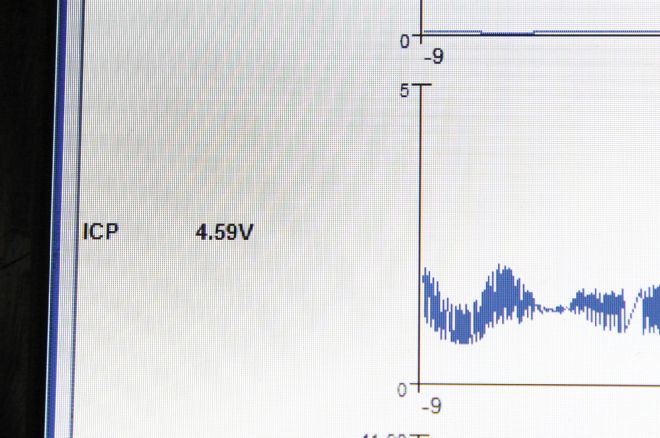

To get an idea how well DieselSite's stock output high-pressure oil pump was performing, we also data-logged ICP voltage. With roughly 4.6 volts holding strong throughout the run—meaning it maintained more than 3,400 psi of injection control pressure (ICP)—we now know the pump is both healthy and capable of supporting the 205cc injectors.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors Dyno

While we weren't able to pull off our typical sweep from 2,200 rpm to 3,700 rpm, backing down the load applied by the dyno (30 percent vs. 35 percent) and starting the run at 2,500 rpm kept the converter from slipping and got us a decent horsepower number. Because the transmission's slip rate predictably decreased as engine rpm increased, it's unclear how big of a horsepower penalty we paid with the slipping converter. It might've cost us 5, 10, maybe even 20 hp, but there is no definitive way to prove it. Either way, we picked up some power over last time and got past the 550hp mark.

*Dyno pull was made in Fourth gear (converter locked)

*Dyno run began at 60 mph and ended at 95 mph

*30 percent load applied

*DynoJet correction factor

| 2003 Ford F 250 Super Duty 01 Elite Diesel Engineerings 205cc Tow Power Plus Injectors

| 2003 Ford F 250 Super Duty 01 Elite Diesel Engineerings 205cc Tow Power Plus Injectors

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 03

Before installing the 205s, we coated the injector O-rings with petroleum jelly. This simply eases the process of getting the injectors into their respective bores in the heads.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 03

Before installing the 205s, we coated the injector O-rings with petroleum jelly. This simply eases the process of getting the injectors into their respective bores in the heads.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 02

Elite Diesel Engineering's 205cc Stage 2+ injectors are a step bigger than the 185cc Stage 2 units we made 538 hp with in Part 8 (January '14). They utilize eight-hole, 80-percent-larger-than-stock nozzles, which makes them 205/80s. They retail for $3,400. Elite also offers a Stage 2+ DIY injector kit for the do-it-yourselfer. It retails for $1,649.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 02

Elite Diesel Engineering's 205cc Stage 2+ injectors are a step bigger than the 185cc Stage 2 units we made 538 hp with in Part 8 (January '14). They utilize eight-hole, 80-percent-larger-than-stock nozzles, which makes them 205/80s. They retail for $3,400. Elite also offers a Stage 2+ DIY injector kit for the do-it-yourselfer. It retails for $1,649.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 04

Once each new injector was in, the injector hold-downs were torqued to the recommended 24 ft-lb spec from Ford.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 04

Once each new injector was in, the injector hold-downs were torqued to the recommended 24 ft-lb spec from Ford.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 05

From there, the log-style oil rails ('03 engines) were installed on each bank, followed by the valve covers. Then the truck was fired up for the first time.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 05

From there, the log-style oil rails ('03 engines) were installed on each bank, followed by the valve covers. Then the truck was fired up for the first time.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 07

Changing the look of the truck a bit, we also added a set of Bushwacker 2-inch pocket-style flares this month. 4Wheel Parts got the call on this one, while Knoles Performance Solutions took care of the paint matching.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 07

Changing the look of the truck a bit, we also added a set of Bushwacker 2-inch pocket-style flares this month. 4Wheel Parts got the call on this one, while Knoles Performance Solutions took care of the paint matching.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 06

We finally got a set of traction bars on Project Outcast to help keep the rear 10.5 still during hard launches and spirited street driving. The Pro Comp ladder bars were also purchased through our friends at 4Wheel Parts and will definitely improve our 60-foot times at the track. It was nice to see the rear end settled down on the dyno, too.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 06

We finally got a set of traction bars on Project Outcast to help keep the rear 10.5 still during hard launches and spirited street driving. The Pro Comp ladder bars were also purchased through our friends at 4Wheel Parts and will definitely improve our 60-foot times at the track. It was nice to see the rear end settled down on the dyno, too.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 08

Even with the 205cc injectors in the mix, the 64mm Powermax-SSX (installed in Part 8) is performing flawlessly. With the bigger injectors, it's even more responsive, keeps EGT very reasonable, and provides awesome driveability. It made 42 psi of boost on the dyno and makes a little more than that on the street.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 08

Even with the 205cc injectors in the mix, the 64mm Powermax-SSX (installed in Part 8) is performing flawlessly. With the bigger injectors, it's even more responsive, keeps EGT very reasonable, and provides awesome driveability. It made 42 psi of boost on the dyno and makes a little more than that on the street.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 09

Not sure how much more the stock TorqShift transmission would be able to handle, we made the trip to the dyno at Randall's Performance and hoped for the best. Unfortunately, our luck ran out this time. Shortly after the 35 percent load was applied to the truck (with the torque converter locked, and in Fourth gear), dyno operator Brian Randall sensed what felt like torque converter slippage.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 09

Not sure how much more the stock TorqShift transmission would be able to handle, we made the trip to the dyno at Randall's Performance and hoped for the best. Unfortunately, our luck ran out this time. Shortly after the 35 percent load was applied to the truck (with the torque converter locked, and in Fourth gear), dyno operator Brian Randall sensed what felt like torque converter slippage.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 10

To find out how bad the converter was slipping, the guys at Randall's connected to the truck's OBD-II port and used Ford's IDS (integrated diagnostic system) to log a run. The number circled here shows the transmission's input shaft is turning 179 rpm less than the engine, indicating torque converter slip.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 10

To find out how bad the converter was slipping, the guys at Randall's connected to the truck's OBD-II port and used Ford's IDS (integrated diagnostic system) to log a run. The number circled here shows the transmission's input shaft is turning 179 rpm less than the engine, indicating torque converter slip.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 11

To get an idea how well DieselSite's stock output high-pressure oil pump was performing, we also data-logged ICP voltage. With roughly 4.6 volts holding strong throughout the run—meaning it maintained more than 3,400 psi of injection control pressure (ICP)—we now know the pump is both healthy and capable of supporting the 205cc injectors.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors 11

To get an idea how well DieselSite's stock output high-pressure oil pump was performing, we also data-logged ICP voltage. With roughly 4.6 volts holding strong throughout the run—meaning it maintained more than 3,400 psi of injection control pressure (ICP)—we now know the pump is both healthy and capable of supporting the 205cc injectors.

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors Dyno

While we weren't able to pull off our typical sweep from 2,200 rpm to 3,700 rpm, backing down the load applied by the dyno (30 percent vs. 35 percent) and starting the run at 2,500 rpm kept the converter from slipping and got us a decent horsepower number. Because the transmission's slip rate predictably decreased as engine rpm increased, it's unclear how big of a horsepower penalty we paid with the slipping converter. It might've cost us 5, 10, maybe even 20 hp, but there is no definitive way to prove it. Either way, we picked up some power over last time and got past the 550hp mark.

*Dyno pull was made in Fourth gear (converter locked)

| 2003 Ford F 250 Super Duty Elite Diesel Engineerings Injectors Dyno

While we weren't able to pull off our typical sweep from 2,200 rpm to 3,700 rpm, backing down the load applied by the dyno (30 percent vs. 35 percent) and starting the run at 2,500 rpm kept the converter from slipping and got us a decent horsepower number. Because the transmission's slip rate predictably decreased as engine rpm increased, it's unclear how big of a horsepower penalty we paid with the slipping converter. It might've cost us 5, 10, maybe even 20 hp, but there is no definitive way to prove it. Either way, we picked up some power over last time and got past the 550hp mark.

*Dyno pull was made in Fourth gear (converter locked)