We’ve all seen it at sled pulls, drag races, or even just out on a muddy road: A truck will be going along fine, until one tire loses traction and starts spinning. This is because many diesel trucks (especially older ones) came with an open differential, which allows both wheels to turn independently of each other. While this is great for tight turns, for virtually all other types of performance, having two-tire traction instead of one is preferable.

| two Tire Fryer Differential Upgrade detroit Locker Install

Our own Project Rust Bucket, an ’89 Dodge D250, had a Dana 70 with an open differential, and it was constantly giving us trouble. Although the 5.9L VE-pumped Cummins engine made “only” 487 rwhp, in a 5,000-pound truck, that’s quite a bit. Combine that with street tires, and traction through First, Second, and Third gear all the way up to freeway speeds was non-existent. Recently, we almost got stuck on a steep hillside while trying to back up, and the decision was made—it was time for a locker.

"Finally, now we can do some good burnouts!"

After the installation of our Eaton Detroit Locker, we can honestly say this is one of the few products we should have purchased a long time ago. Maintain a constant speed around a corner or lift off the throttle, and one side will unlock, providing an open differential experience. However, unlike an open differential, both tires are always there for traction with even the slightest throttle input. Also, unlike a limited-slip, there are no clutches to wear out, no additives needed during gear oil changes, and no chance of getting left in open-diff mode when you need traction the most. Best of all, Detroit makes a locker for Dana 44s, 50s, 60s, 70s, and 80s; Ford 10¼- and 10½-inch axles; as well as the AAM axles found in newer trucks, so there’s a Detroit Locker available for virtually every diesel application.

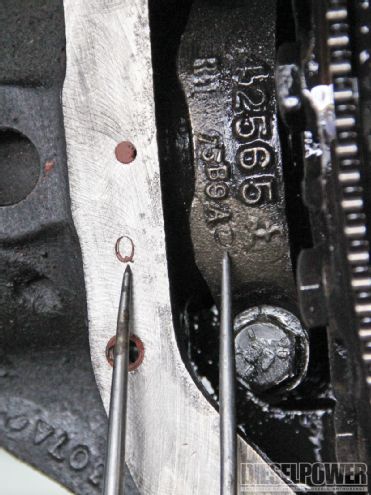

| The very first step of our Detroit Locker install involved removing the axles. Our Dana 70 featured a full-floating design, so with the removal of the retaining nuts, our axle was ready to come out.