2003 Ford Expedition Transmission Cooling - The Coolest Tranny

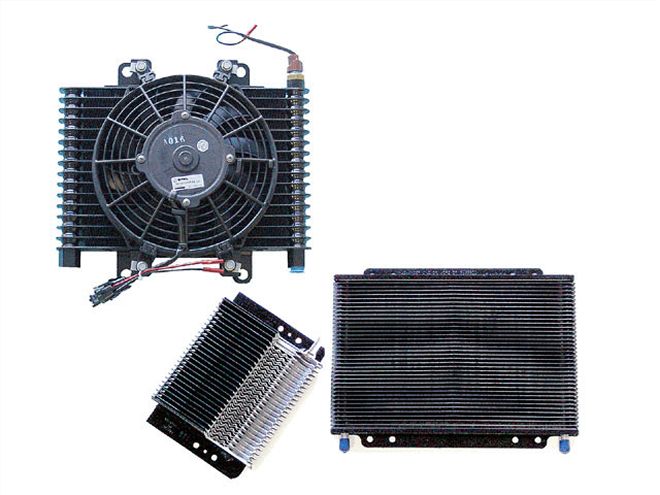

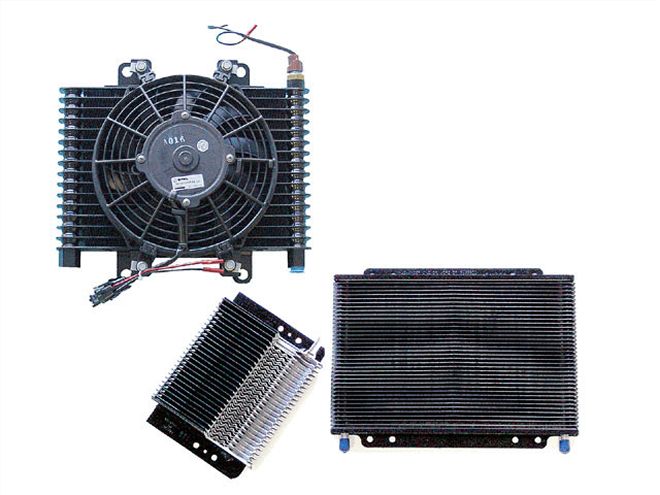

| B&M offers two distinctly different designs of coolers for engine oil and transmission fluid. The stacked-plate cooler, seen in the cutaway, is extremely durable and great for high-speed driving. The Hi-Tek cooler, outfitted with an electric fan, offers superior cooling at low speeds when ambient airflow is unavailable.

Long transmission life is dependent on one main premise: heat and how to dissipate it. Too much heat will kill any transmission, no matter how good the internal parts may be. Whether you're cruising, racing, playing in the dirt, or towing, your automatic is creating friction and heat, and is relying on the transmission fluid as a source of coolant and lubrication.

While most every modern vehicle uses a radiator-based cooling tank for automatic transmission fluid, this is rarely adequate for the rigors of heavy freeway driving or towing. In some instances, an auxiliary fluid cooler may be standard equipment, but this by no means is the end of the line for cooling.

We wanted to show you how far the technology of cooling has come, and to illustrate this, we called the transmission experts at B&M Racing & Performance Products. According to the V.P. of Engineering at B&M, "Fin and tube coolers only scratch the surface of cooling technology. Fin-and-plate and stacked-plate design coolers have shown a 25-30 percent increase in efficiency while creating 15 times less flow restriction."

So, what are the differences in cooler designs? First, let's look at the most traditional type of cooler, the fin-and-tube style. This type of cooler uses a single tube to move the flow of fluid from one end of the cooler to the other, while being cooled by the air traveling over the small fins running top to bottom, much like a radiator. While this design of cooler does help remove heat, it has the least amount of surface area in contact with the fluid.

The most compact cooler design is the stacked-plate model. This construction can be explained as a honeycomb that allows oil to travel from one end to the other while air travels over the surface. In addition to being very efficient for its size and weight, the stacked-plate cooler is extremely durable, thus great for trucks that will see high-speed debris, such as vehicles used off-road, or in inclement weather.

The third and most efficient type of cooler is the fin and plate-style cooler, which uses small hollow plates to move the fluid from one side of the cooler to the other. This style of cooler allows more fluid to be exposed to the plates, thus improving cooling efficiency. Similar to the fin-and-tube cooler, the fin-and-plate cooler also uses vertical fins to catch ambient air and remove the heat. This design allows the oil to move freely inside the cooler, keeping restriction to a minimum. This is also the only type of cooler available from B&M offering the Hi-Tek electric fan system.

Our donor vehicle was an '03 Expedition, basically stock, aside from tires and a 2-inch drop kit. Used mainly for toolin' around town and the occasional trip to the river, keeping the tranny cool was a must. Our weapon of choice is a B&M Hi-Tek fin-and-plate cooler, sporting a 12-volt suction fan and built-in thermostatic fan control for more consistent operating temperatures. Although our Expedition had a small plate-and-fin cooler, the upgrade was necessary for the long-term survival of our stock transmission when towing. Having an OE cooler made the install simple; all the lines were preexisting and ready to be connected to the new, 50-percent larger Hi-Tek cooler.

| B&M offers two distinctly different designs of coolers for engine oil and transmission fluid. The stacked-plate cooler, seen in the cutaway, is extremely durable and great for high-speed driving. The Hi-Tek cooler, outfitted with an electric fan, offers superior cooling at low speeds when ambient airflow is unavailable.

Long transmission life is dependent on one main premise: heat and how to dissipate it. Too much heat will kill any transmission, no matter how good the internal parts may be. Whether you're cruising, racing, playing in the dirt, or towing, your automatic is creating friction and heat, and is relying on the transmission fluid as a source of coolant and lubrication.

While most every modern vehicle uses a radiator-based cooling tank for automatic transmission fluid, this is rarely adequate for the rigors of heavy freeway driving or towing. In some instances, an auxiliary fluid cooler may be standard equipment, but this by no means is the end of the line for cooling.

We wanted to show you how far the technology of cooling has come, and to illustrate this, we called the transmission experts at B&M Racing & Performance Products. According to the V.P. of Engineering at B&M, "Fin and tube coolers only scratch the surface of cooling technology. Fin-and-plate and stacked-plate design coolers have shown a 25-30 percent increase in efficiency while creating 15 times less flow restriction."

So, what are the differences in cooler designs? First, let's look at the most traditional type of cooler, the fin-and-tube style. This type of cooler uses a single tube to move the flow of fluid from one end of the cooler to the other, while being cooled by the air traveling over the small fins running top to bottom, much like a radiator. While this design of cooler does help remove heat, it has the least amount of surface area in contact with the fluid.

The most compact cooler design is the stacked-plate model. This construction can be explained as a honeycomb that allows oil to travel from one end to the other while air travels over the surface. In addition to being very efficient for its size and weight, the stacked-plate cooler is extremely durable, thus great for trucks that will see high-speed debris, such as vehicles used off-road, or in inclement weather.

The third and most efficient type of cooler is the fin and plate-style cooler, which uses small hollow plates to move the fluid from one side of the cooler to the other. This style of cooler allows more fluid to be exposed to the plates, thus improving cooling efficiency. Similar to the fin-and-tube cooler, the fin-and-plate cooler also uses vertical fins to catch ambient air and remove the heat. This design allows the oil to move freely inside the cooler, keeping restriction to a minimum. This is also the only type of cooler available from B&M offering the Hi-Tek electric fan system.

Our donor vehicle was an '03 Expedition, basically stock, aside from tires and a 2-inch drop kit. Used mainly for toolin' around town and the occasional trip to the river, keeping the tranny cool was a must. Our weapon of choice is a B&M Hi-Tek fin-and-plate cooler, sporting a 12-volt suction fan and built-in thermostatic fan control for more consistent operating temperatures. Although our Expedition had a small plate-and-fin cooler, the upgrade was necessary for the long-term survival of our stock transmission when towing. Having an OE cooler made the install simple; all the lines were preexisting and ready to be connected to the new, 50-percent larger Hi-Tek cooler.

| B&M offers two distinctly different designs of coolers for engine oil and transmission fluid. The stacked-plate cooler, seen in the cutaway, is extremely durable and great for high-speed driving. The Hi-Tek cooler, outfitted with an electric fan, offers superior cooling at low speeds when ambient airflow is unavailable.

Long transmission life is dependent on one main premise: heat and how to dissipate it. Too much heat will kill any transmission, no matter how good the internal parts may be. Whether you're cruising, racing, playing in the dirt, or towing, your automatic is creating friction and heat, and is relying on the transmission fluid as a source of coolant and lubrication.

While most every modern vehicle uses a radiator-based cooling tank for automatic transmission fluid, this is rarely adequate for the rigors of heavy freeway driving or towing. In some instances, an auxiliary fluid cooler may be standard equipment, but this by no means is the end of the line for cooling.

We wanted to show you how far the technology of cooling has come, and to illustrate this, we called the transmission experts at B&M Racing & Performance Products. According to the V.P. of Engineering at B&M, "Fin and tube coolers only scratch the surface of cooling technology. Fin-and-plate and stacked-plate design coolers have shown a 25-30 percent increase in efficiency while creating 15 times less flow restriction."

So, what are the differences in cooler designs? First, let's look at the most traditional type of cooler, the fin-and-tube style. This type of cooler uses a single tube to move the flow of fluid from one end of the cooler to the other, while being cooled by the air traveling over the small fins running top to bottom, much like a radiator. While this design of cooler does help remove heat, it has the least amount of surface area in contact with the fluid.

The most compact cooler design is the stacked-plate model. This construction can be explained as a honeycomb that allows oil to travel from one end to the other while air travels over the surface. In addition to being very efficient for its size and weight, the stacked-plate cooler is extremely durable, thus great for trucks that will see high-speed debris, such as vehicles used off-road, or in inclement weather.

The third and most efficient type of cooler is the fin and plate-style cooler, which uses small hollow plates to move the fluid from one side of the cooler to the other. This style of cooler allows more fluid to be exposed to the plates, thus improving cooling efficiency. Similar to the fin-and-tube cooler, the fin-and-plate cooler also uses vertical fins to catch ambient air and remove the heat. This design allows the oil to move freely inside the cooler, keeping restriction to a minimum. This is also the only type of cooler available from B&M offering the Hi-Tek electric fan system.

Our donor vehicle was an '03 Expedition, basically stock, aside from tires and a 2-inch drop kit. Used mainly for toolin' around town and the occasional trip to the river, keeping the tranny cool was a must. Our weapon of choice is a B&M Hi-Tek fin-and-plate cooler, sporting a 12-volt suction fan and built-in thermostatic fan control for more consistent operating temperatures. Although our Expedition had a small plate-and-fin cooler, the upgrade was necessary for the long-term survival of our stock transmission when towing. Having an OE cooler made the install simple; all the lines were preexisting and ready to be connected to the new, 50-percent larger Hi-Tek cooler.