Siping has been around since the first man, John Sipe, kept slipping on the slick floors of his job. Somehow, he figured out that a few shallow slices across the soles and heels of his shoes would help him have better traction on the slick floors.

It worked so well, it has been said, that he patented the process back in the '20s. Of course, tire manufacturers are no dummies either and it wasn't long until they discovered how well it actually worked on tires for highway use. Many of today's tires are siped in the tire molds to give additional traction. Tire manufacturers have almost turned this idea into an art form, with sipes running in zigzag patterns, while others make geometric shapes. Not all new tires have siping, and this leaves the aftermarket open for the siping business.

Back in 1978, a study by the U.S. National Safety Council found siping improved stopping distance by 22 percent, breakaway traction by 65 percent, and rolling traction by 28 percent on glare ice (ice with a smooth, shiny surface). The tire tread block shapes, groove configurations, and siping all effect tire noise pattern and traction characteristics. Typically wide, straight grooves have a low noise factor and good water removal. More lateral grooves usually increase traction. You'll notice on a lot of new tires the siping is done across the larger tread blocks and usually just down the center part of the tread. Siping near the outside edges of the tire is not recommended and is done only on request. Experience has shown that siping to the outside can cause chipping (breaking off the rubber) on the edges.

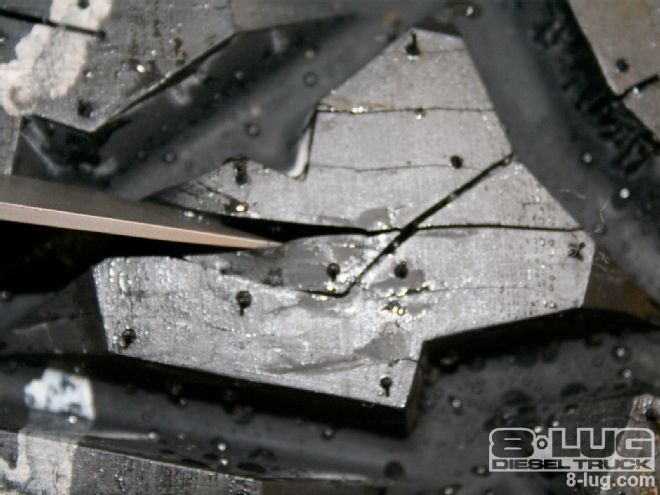

Up to a point, more sipes give more traction in snow, ice, and mud. According to Saf-Tee Siping and Grooving in Phoenix, the most effective braking power occurs immediately prior to losing traction. Siping extends that window by giving the existing tread a helping hand with the dozens of additional gripping edges. It's these microedges that reduce the distance needed for braking on wet and icy roads. A smoother ride and extended tire life is provided by this microflexibility. This built-in siping feature helps absorb road surface contact, thereby reducing wear on a tire's carcass and sidewalls. Siping also reduces the heat and its effects on your tires by allowing it to cool. The air passes between these siping slices once they have opened after driving on them. Initially after the tires have been siped by a tire store, the slices are closed. But after driving for a couple thousand miles or more, the slices start to open slightly and become more visible. This is normal-not to worry. They are still providing all the good qualities we have mentioned above (see the photos).

Most tires (new, retreaded, or used) can be siped as long as they have plenty of rubber left. The normal siping depth is about 1/4-inch or less. Saf-Tee Siping and Grooving says as long as 5/32-inch of tread remains, sipe it. Be sure to ask your tire store if siping voids the tire warranty. The Rubber Manufacturers Association neither endorses nor condemns the procedure but notes that siping must be done properly to avoid ruining a tire, and that usually means going too deep. Also, check your state's vehicle codes. A vehicle with aftermarket siping being operated in Virginia will fail the tire test during a vehicle inspection.

As you'll notice from the photos, I had to go to a tire dealer that did siping so I could see for myself just how siping was performed by a machine. Since I live in the Northwest, a lot of tires are siped here due to the weather and road conditions. I went to Larry's Tire/Coos Bay Off-Road (in Oregon) and watched a set of 4WD tires get the siping treatment. With the tire mounted in the machine so it could rotate, the siping head held a round cutting wheel that had been cut to the center so the wheel could be opened slightly. This helped rotate the tire like threads on a bolt to pull it forward as the cutting wheel spun across the face of the rubber while being lubricated with water. The process went pretty fast over the rubber surface and took about 10 minutes per tire. This siping went from side to side across the tire face. The man siping the tires, Brad Haga, has siped all his tires for years and said he gets better traction on snow, ice, mud, rock crawling, pavement, and even gravel roads. However, he said off-road and on gravel, the siping could pick up little rocks and woodchips in the slices, but traction was still great.

It's the best traction enhancement you can do for a tire except adding studs at the shoulders of the tires and siping down the center. Haga says they have many customers who want both done to their tires-and that's from their winter experience logging in mud, ice, and snow (actually, just getting to the job site). As Dennis Baldwin explains: "Why sipe your tires? In one word, traction. Nothing can beat a siped tire on ice and snow (except studded and siped tires). It is the more attractive and more graceful version of chained tires. Siped tires generally stop faster, handle better, and last longer."

Having your tires siped at your local tire store can cost around $12 to $20 per tire, depending on tire diameter. However, if you are one of those who wants to do it yourself, there are handheld siping and grooving guns available. Afco Racing, a speed shop in Boonville, Indiana, sells a 110-volt unit with a No. 4 head for $74 and a 220-volt with a No. 5 head for $81. They call them tire groovers, but these guns actually do both jobs for the real off-roaders who want to remove rubber as well to make a bigger lug pattern and siping. There are a number of different heads for different siping depths, so total cost may be more than just the gun price if you want other options. The gun with a heated head is the one to have, since it softens the rubber and makes it easier to cut.

Most of our 8-Lug readers probably tow on occasion and will reap all the good benefits of siping while towing or hauling heavy loads as well. As a last word, I would say to ask about siping and tire warranty and check your state's vehicle code manual to make sure your state agrees with siping. The only place where I found that siping is not used is for racing. Apparently, during heavy cornering when racing, the slices rub against each other and form more heat than straight highway driving.