Serpentine belt drive systems are common on today's cars and light trucks. The advantage of increased surface area of a wide multi-grooved belt, along with the ability of the system to wrap the belt around the drive pulleys instead of over them, makes this belt system long lasting and trouble-free. Common problems with this system include normal wear of the belt and belt tensioner. Proper maintenance includes checking the tensioner for wear.

Visually inspect the belt tensioner for misalignment caused by a worn spring loading mechanism. This condition is visible at the pivot point of the tensioner, and the separation of the two halves of the tensioner can be easily seen with the naked eye.

Check spring loading of the belt by looking at the tension gauge cast into the two halves of the tensioner. The inner piece will have two arrows cast into the metal, and the outer piece will have one arrow cast into the metal. The outer arrow should point between the two inner arrows. If the arrows are not lined up properly, replace the belt.

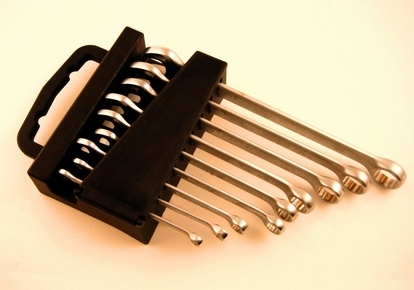

With a 15mm wrench, check the tensioner for binding. If the tensioner is released and does not return to its original position, replace the tensioner.

Remove the belt by compressing the tensioner and slipping the belt off the pulley. Spin the pulley while listening and feeling for roughness. Any rough noise or vibration will be amplified when the pulley is under tension. Replace the pulley if these symptoms occur.