At first blush, a throttle seems so simple: the right pedal pulls on a cable that's connected to a shaft. This shaft rotates and opens a butterfly valve to let air into the engine. However, even the simplest symptoms can have binds and breakages, and the relentless march of technology has only created further opportunity for malfunction in this once-analog system.

Simple throttle cables can sometimes bind on the surfaces they come in contact with, but this problem is unlikely unless you're driving a bona fide antique. Breakage of crucial components is more common. Some of these components include the E-clip that secures the cable to the external valve arm, the retainer that secures the throttle cable to the bracket and the throttle-return spring.

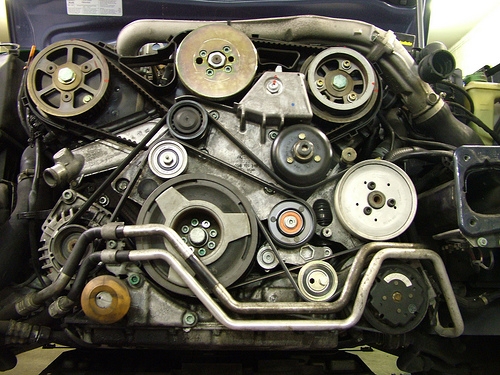

The throttle position sensor (TPS) is usually attached to the throttle body (main air valve), and tells the computer how far open it is. This is crucial information when calculating the proper amount of fuel required for operation because the computer's main job is to maintain the proper ratio of air to fuel.

TPS failure can lead to engine stalling, inconsistent idle and inconsistent shifting in cars equipped with computer-controlled automatic transmissions. When a TPS begins to malfunction, stalling will usually only occur under extreme deceleration. Without up-to-the-milisecond information on throttle position, the computer simply assumes that you're doing the same thing you were two seconds ago, and will continue to inject cruise amounts of fuel until it notices a change in air-fuel ratio.

Under extreme deceleration, the throttle butterfly suddenly snaps shut, drastically reducing airflow to the engine. If the computer continues to inject cruise-amounts of fuel without enough air, it will flood the engine with gasoline and stall the car.

Many new cars use a drive-by-wire system, in which there is no mechanical connection from throttle body to gas pedal. This system uses a potentiometer on the gas pedal to measure throttle input, which is interpreted by the computer and sent to a servomotor on the throttle body. Drive-by-wire systems allow the computer to modulate the throttle for better fuel economy, and to increase stability and traction by controlling wheel-spin on high-powered cars.

Drive-by-wire systems are hardly in their infancy in the automotive world, have been pretty well sorted out over the years, but will break and fail eventually. These problems are generally easy to diagnose, because the car will either stall or operate only under idle. Most drive-by-wire malfunctions are due to gas-pedal sensor failure, as opposed to being computer or servomotor-related.