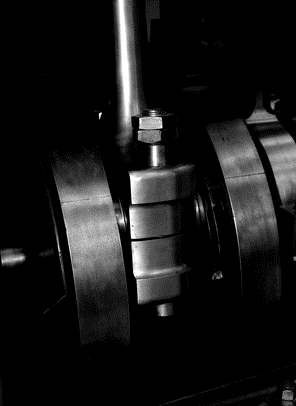

The harmonic balancer, also called the crankshaft damper or crankshaft pulley, keeps the vehicle's engine from vibrating unnecessarily while running. Some harmonic balancers have two-piece construction, consisting of a pressure ring and rubber insert sandwiched between two circular plates of steel. The pulley can drive either a single serpentine belt or multiple accessory belts. When the harmonic balancer needs to be removed, special care and some specialty tools must be used to avoid major damage to the harmonic balancer and the crankshaft. A few techniques can be used without the aid of air impact tools to keep the harmonic balancer immobilized while removing the bolt.

Purchase or put down a loan deposit for the SST (specialty service tool) that you will need to immobilize your harmonic balancer. Supply the make, model, year and engine size of your vehicle to the parts clerk at the auto store or dealership. Note in your owner's manual the rotation of your engine as you face the front of the vehicle, along with the thread direction (right- or left-hand threads) of your harmonic balancer, to include with the information.

Make sure that you have placed the vehicle on jack stands, front and rear, using a floor jack. All components should be removed to gain access to the front part of the engine where the harmonic balancer sits. Slide under the vehicle with the specialty tool. You will either have flange notches or three threaded holes on the inside of the harmonic balancer pulley. Refer to the tool directions for the proper connection features of your specialty tool.

Attach the outer flange of the tool by screwing it to the harmonic balancer pulley. Start the bolts in by hand -- there should be three of them. Place a socket end on one bolt, and using a ratchet wrench, turn the bolt in (clockwise) about five turns. Go to the next two bolts and do the same. Tighten all three bolts down, alternating evenly so you do not cock the flange off center. Make sure all the bolts tighten flush, holding the tool flange against the harmonic balancer.

Connect the long tool arm to the tool flange, positioning the arm down toward the floor on the left side of the engine (for right-hand thread removal). You can place a long pipe over the tool arm so it extends to the floor, or you can wedge the tool arm between two solid pieces of frame. This will immobilize the harmonic balancer pulley so you can place a socket and ratchet on the end of the pulley bolt.

Place the harmonic balancer removal tool up against the harmonic balancer pulley, and align the flange notches on the tool to the notched inserts on the harmonic balancer pulley (if you have this specialty tool configuration). Adjust the long tool arm to reach the floor or wedge in between to solid pieces of frame. Place it on the left side of the engine for right-handed thread removal, or on the right side for left-handed threads (consult your owner's manual). You can now remove the harmonic balancer, with the pulley immobilized.