Pneumatic cylinders are in widespread use in industry wherever quick, powerful linear actuation of moving gates, valves, levers and presses is required. Pneumatic cylinders come with bores and strokes in sizes ranging from fractions of an inch all the way up to several feet. They are powered by compressed air at pressures ranging from a few pounds to hundreds of pounds per square inch and can provide thousands of pounds of push or pull force.

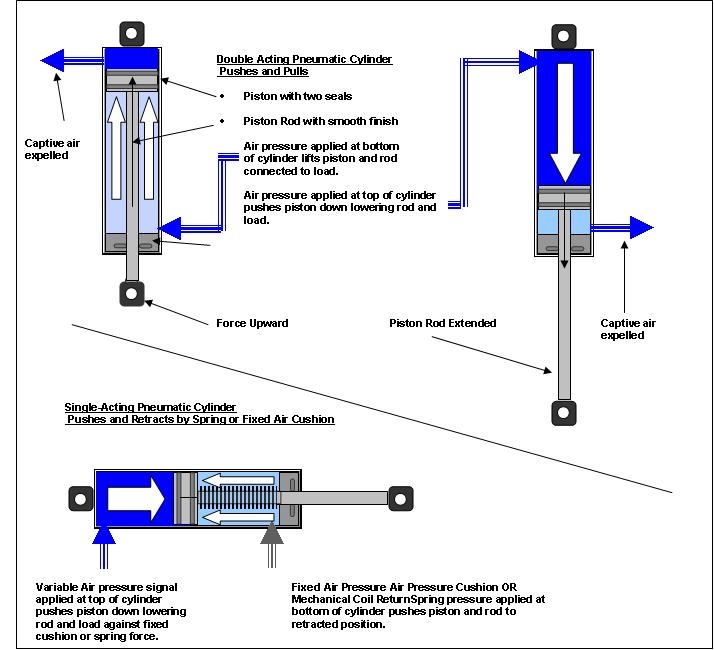

Pneumatic cylinders are available in a number of types, including single-acting, double-acting, and double-acting with piston rod attachments on both ends of the cylinder.

Single-acting cylinders apply pneumatic air pressure to one end of the piston to extend or retract it. Thus, they perform work in only one direction of movement. To return the piston to its non-pressurized or rest position, single-acting cylinders can use either opposing springs or the opposing force or load of the application itself. For example, cylinders used in car jacks use the weight of the jacked vehicle to return the cylinder to its rest position. Cylinders that are used to open ventilation dampers may have an integral spring to return the cylinder, and the damper, to its rest position.

Double-acting cylinders apply pneumatic pressure to both sides of the piston alternately for back-and-forth actuation in such devices as reciprocating pumps, reciprocating saws or presses, or part insert/remove mechanisms. They perform work in both directions of movement. These cylinders do not require a return spring unless a specific rest position is required whenever the device is not powered.

Pneumatic cylinders employ a smooth-bore cylinder with a piston affixed to a piston rod, with several seals between the piston and cylinder. They most often consist of metal components, although many composites are used for special applications. They are available with a variety of end fittings and pneumatic piping and tubing connections.

Compressed-air cylinders are used in a number of automotive and building applications, including jacks and hoists, doors, gates and hatch motors. By far, the greatest use is in the industrial realm, where pneumatic cylinders are used as actuators for valves, lift gates, hoists and machines.

Some pneumatic cylinder applications do not require external power. They simply act as dynamic dampers or shock absorbers. The most common example is the door-closer cylinder on a storm door that keeps the door from opening or closing too sharply, while providing a spring that gently closes the door.