Harry Wagner

Contributor

Harry Wagner

Contributor

Shackles? All those do is connect the springs to the frame. What sort of innovation can there be related to shackles? This is a valid question. Shackles are the least glamorous component of a leaf-spring suspension, but they can still have a large effect on suspension travel and ride quality.

As a leaf spring travels through its range of motion, the effective length of the spring changes. A highly arched spring will gain length as it compresses, whereas a completely flat spring will effectively get shorter as the spring both compresses and extends. If the shackles are not properly engineered to accommodate this range of motion, they will bottom out, resulting in a harsh ride and poor handling.

In recent years, options beyond the factory stamped steel have emerged that have the potential to provide everything from increased travel to improved ride to more precise handling. What follows are some of the common (and not-so-common) aftermarket shackle options.

All-Pro offers replacement shackle hangers that incorporate a Johnny Joint for additional flex and less spring fatigue. These work in conjunction with All-Pro's zinc-plated steel shackles that feature greasable bushings. The mounts must be welded to the frame, making them the perfect addition when you need to change your shackle mounts to accommodate longer leaf springs.

Con-Ferr is one of the oldest names in lift shackles, offering applications for nearly every truck on the market for 40 years. All shackles are manufactured from 3/8-inch steel and gold zinc-plated for instant recognition. The shackles feature a jig-welded center brace for increased strength and stability, and are available in a variety of lengths and widths.

Currie offers a wide variety of shackles for Jeep CJs, YJs, and XJs. The towbar shackles incorporate an extra mounting pin to allow Currie's towbar to be attached to the shackle. This is perfect for vehicles with tubular front bumpers that do not contain a flat mounting surface for traditional towbar mounts. The quick-release pins allow you to easily remove the towbar when you get to your destination. All Currie shackles are constructed from 1/4-inch steel and feature greasable polyurethane bushings and a bolt-in center brace to offer improved stability.

Nth Degree Mobility's Zig-Zag hangers get rid of the rear shackles on your CJ or YJ altogether. After a rear spring becomes totally unloaded, it can fall away at the shackle end because there is no direct connection where the shackle had been. The amount of separation is limited only by your shocks and springs. At the same time, the product actually increases the side-to-side stiffness of your suspension for better handling: Since the spring ends are connected to each other and the frame by the Zig-Zag assembly, they cannot twist due to cornering loads on pavement.

Mountain Off Road Enterprises offers dog-leg shackles for CJs and YJs that allow for the use of a longer spring and help clear frame-mounted obstructions such as body mounts and bumpers. All M.O.R.E. shackles are constructed from 3/8-inch steel and feature plasma-cut holes and greasable polyurethane bushings. Other features unique to M.O.R.E. are the option of 1/2- or 9/16-inch shackle bolts and its Zerk protector, which fits over the bolt head and keeps the grease nipple from being torn off the shackle bolt.

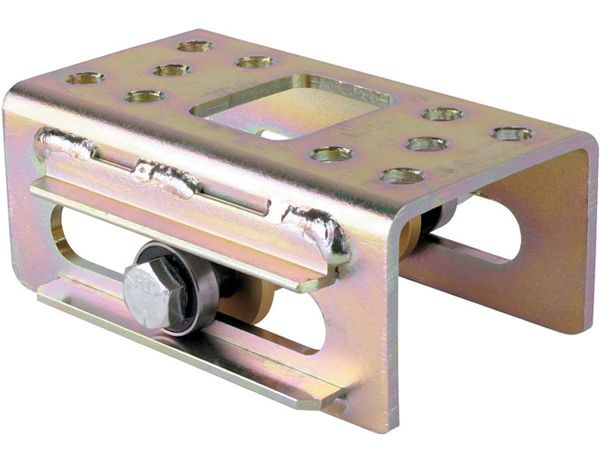

Longer shackles are sometimes necessary to allow for a full range of motion, but they also hang down further from the frame and rob ground clearance. Thankfully, Speedway Motors offers a product that allows more spring length changes and actually sits flush against the frame. Designed for race cars, the Sliding Shackles work just as their name implies. Instead of moving in an arch, the spring slides back and forth along heavy-duty roller bearings.

Does your 3/4- or 1-ton truck ride down the road like a go-cart when the bed is empty? Changing to softer rear springs can provide a cushy ride around town, but as soon as you hook up the trailer or put a load in the bed, the nose of the truck shoots skyward. Velvet-Ride Shackles, manufactured by Lord Corporation, bolt in place of your stock shackles and cure the poor ride present when the bed is empty without sacrificing load-carrying ability. The product is based on the Torsilastic rubber torsion-spring technology, which consists of an inner steel shaft surrounded by a rubber cylinder encased in an outer shell of high-strength metal. When the shaft is rotated in relation to the outer shell, the rubber resists the twisting effect and provides support along with vibration isolation. As the force is released, it returns to its original position while maintaining its vibration-isolating capabilities.

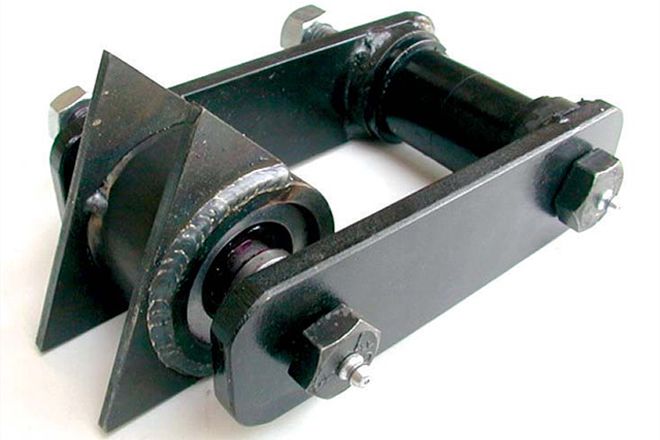

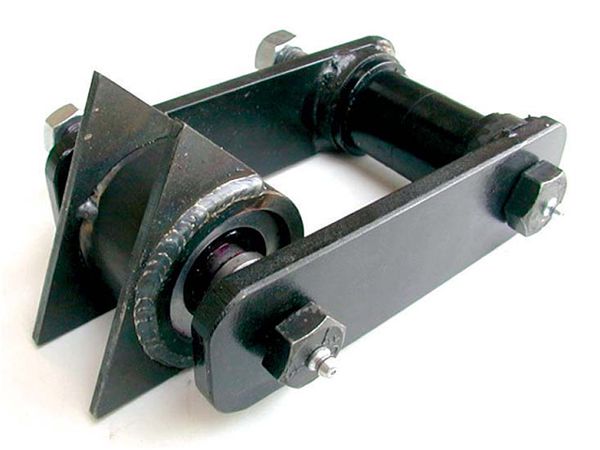

Revolver shackles feature a unique shackle design and rotate to allow leaf springs to flex and compress without additional spring stress. Teraflex Revolver shackles never rest against the frame because they are self-supporting and will stay folded against themselves on level ground. It is best to install longer shocks and brake lines (or limiting straps) in conjunction with Revolver shackles, as additional travel gains of more than 6 inches are not uncommon.

Two shackles that are exactly the same can perform differently, and the same shackle can perform differently over time. How is this possible? There are other factors beyond the shackle that affect how it operates. Shackles are just one component in your suspension system.

Rubber bushings are commonly found in stock shackles, and sometimes available in aftermarket shackles and spring eyes as well. Rubber is generally more flexible than polyurethane, which can offer increased spring and shackle movement on the trail at the expense of handling on the road. Rubber also tends to break down more quickly than polyurethane, meaning more maintenance.

Some polyurethane bushings feature flutes (or grooves) that are used in conjunction with hollow bolts fitted with grease nipples. Grease can be added to the nipples and flow through the flutes, adding lubrication and thus reducing friction and resistance. The grease tends to increase the life of bushings. However, it can attract dust and dirt and needs to be flushed if you travel in these conditions often. Mountain Off Road Enterprises even offers steel guards that you can install over the bolt head to protect the grease nipple. These are available for any shackle using 1/2- or 9/16-inch bolts.

One of the most common mistakes we see related to shackles is when owners or installers overtighten the mounting bolts. Doing so restricts shackle movement when the spring compresses and extends, and can even bend the ends of the shackle. Most shackles come with Nylock fasteners that just need to be tightened enough so that they do not loosen over time.

-Harry Wagner