IFS-equipped vehicles offer excellent handling and ride quality for high-speed desert romping and everyday street driving. However, independent front suspension systems lack the crucial range of motion necessary to ensure ample traction on the trail. For this reason, most rockcrawlers prefer the older-style, solid-axle setup. Without low-hanging bracketry and limited articulation, a solid front axle simply works better when the road gives way to boulders. This is why several companies offer kits to convert the factory IFS to the stronger solid-axle arrangement.

One such kit we discovered recently was this new one from the experts over at Marlin Crawler. Designed for '86-'95 Toyota pickups and 4Runners, Marlin's kit provides most of the parts and pieces required for those looking for more articulation, and a stronger front drivetrain. The kit provides 5 full inches of lift and weighs in heavily on the mechanical difficulty scale. We recommend a high-tech know-how and a decent assortment of tools to complete this installation. That's why we enlisted the expertise of Toby Lavender, owner and operator of Triple-X Traction in Seaside, California. You may remember Toby from Top Truck Challenge 2002, where he successfully piloted his flexible flatfender to a Fourth-Place finish. Toby and his crew have completed dozens of clean solid-axle swaps since he started the business five years ago. It's important to understand several technical aspects of a solid-axle conversion before breaking out the torch. So follow along as we highlight the conversion process and showcase some very unique components that will make any IFS truck ready to rock.

9. With the new front axle assembled, Toby positioned it under the truck, checking every detail along the way. Once he felt comfortable with the front driveline angle, he tack-welded the new spring pads in place. He then took a measurement of the front driveline, and then ordered up a pair of CV-equipped driveshafts from South Bay Driveline in San Jose, California. The experts at South Bay Driveline suggested we option in an extra-long slip on the front shaft to prevent problems. The new shafts arrived two days later and looked beautiful. Once the front shaft was installed, Toby completed the final welding on the front axle perches and spring hangers.

10. With 5 inches of lift up front out of the way, it was time to tackle the rear lift. First the rear axle was removed from the truck. Next the gas tank came out. Then Toby installed a pair of Marlin's frenched rear spring hangers into the frame. Though not included in the solid-axle swap kit, we thought these super-clean hangers fit this article well. What they do is prevent the rear spring hangers from hanging up on rocks. To install them, Toby notched the frame with a plasma torch. Then he inserted a hanger and welded it into place. These units are built strong from 1/4-inch-thick plate steel. Once the hangers were in place, the new 5-inch rear leaf springs were installed.

After the installation was complete, we testdrove the 4Runner and found it handled quite nicely on the road. Off-pavement, however, is where the solid axle swap shines brightest.

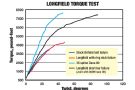

Total Chaos Fabrication of Corona, California, has been building desert-racing-inspired IFS systems for more than a decade. The company's Gen II Caddy Kit for '86-'95 4WD Toyota trucks increases wheel travel and tire clearance with minimal suspension lift to improve high-speed off-road performance. The chromoly upper and lower A-arms are extended 3.25 inches per side and use 2.5x8-inch-stroke coilover shocks to dampen 12 inches of wheel travel without eliminating four-wheel drive. The setup clears 33-inch tires (with fiberglass fenders), and ride height is adjustable between 2 to 4 inches of lift. As a secondary benefit, these suspension modifications actually improve the ride quality and the truck should handle better than stock.

We ordered a Gen II Caddy Kit from ORW to install on a '89 4Runner to compare the performance of an IFS overhaul to a straight-axle conversion. To complete the installation, we ordered a pair of Racerunner 2.5x8-inch remote-reservoir coilover shocks, two 500x18-inch Eibach coil springs and a pair of fiberglass fenders from Glassworks Unlimited. The truck will ride on 15x8 forged alloy wheels from Alcoa and 33x10.50 BFG tires. Visit www.fourwheeler.com for more information about all the parts and a complete installation.

PhotosView Slideshow

PhotosView Slideshow