Rick Péwé

Editor-in-Chief, 4Wheel & Off-Road

Photographers:

Rick Péwé

Rick Péwé

Editor-in-Chief, 4Wheel & Off-Road

Photographers:

Rick Péwé

Axle articulation is much sought-after for maximum off-road performance, especially for crawling over rocks. But the safety gurus have added sway bars and track bars on late-model solid front axle vehicles in the interest of better handling and improved street performance, which has resulted in a corresponding diminishment of dirt driving fun. Many companies offer sway bar disconnects that are quick and easy to use. On the other hand, many owners simply remove the sway bar when they install stiffer springs and they experience no handling differences.

But disconnecting the track bar to get even better articulation is a different story. A track bar is used to control suspension side-to-side shifting, and on most coil-spring suspensions, the track bar is the only suspension component that keeps the axle in its proper place laterally. For instance, when older Broncos and Jeep Cherokees with coil suspensions are lifted, a longer track bar or extension brackets are installed to keep the axle in line and moving properly, while removing it would make the rig unsafe at any speed.

On '87-'95 Jeep Wranglers, a track bar is used with the leaf-spring suspension to provide good road-handling characteristics by limiting side-to-side shifting of the soft suspension. And that same track bar limits the Wrangler's off-road articulation, while taking the bar off and putting it back on for road use is more of a pain than it's worth. The good news is that JKS Manufacturing has come up with a telescoping track bar for leaf-spring Wranglers to retain the good-handling characteristics on the highway and provide up to a 31 percent increase in axle articulation with the simple twist of a wrench. We went to Off Road General Store to check out the installation of the new slip-and-slide mechanism on a Wrangler, so follow along and see how easy articulation increases can be.

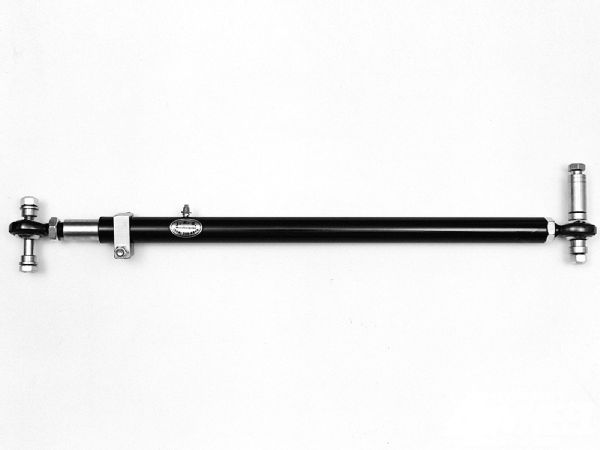

Looking much like a high-tech spear gun, the JKS telescoping track bar is fitted with Teflon-lined Heim joints at each end for the utmost in on-road flexibility and stability. Should the ends ever wear out, they're replaceable. It's unlikely you'll ever need to replace them if you hose them off after grungy use.

PhotosView Slideshow

Looking much like a high-tech spear gun, the JKS telescoping track bar is fitted with Teflon-lined Heim joints at each end for the utmost in on-road flexibility and stability. Should the ends ever wear out, they're replaceable. It's unlikely you'll ever need to replace them if you hose them off after grungy use.

PhotosView Slideshow