Play in the dirt long enough and you're going to break something. It's just a fact of off-road life. Whether it's major or minor breakage depends largely on the driver, but things do happen when playing off-road. Compounding the matter is the fact that factory parts are generally known not to be the strongest. They are chosen to fit a certain price point within the vehicle's design parameters. What this means for the Jeeper is that we end up with parts that, while they can do the job, could be a whole lot better.

One of the weakest points on a JK is the front axle. The Dana 30 front axle that comes standard in the JK (Rubicons get the Dana NG 44 front axle) is not known for being the strongest axle around. The axletubes are thin-wall to save weight, the axleshafts are 27-spline, and the end forgings are just not thick enough to stand up to heavy abuse. All that said, they still stand up to way more abuse than they really should, provided the tire size and vehicle weight doesn't get too large or heavy. While the JK Rubicon's Dana NG 44 is a bit of an upgrade, it shares the same tubes, end forgings, and knuckles with the Dana 30. The only real difference is the size of the differential, a thicker-cut gearset, and the 32-spline axleshafts in the rear.

As the tires get bigger and we add more armor to our Jeeps, bending or breaking the front axle becomes more likely. In fact, it's almost a given. A couple of the more common problems that show up are the end forgings bending and the axletubes bending where they enter the differential housing. The end forgings, or inner-C, is where the knuckles connect to the axle via the ball joints. Hitting enough big bumps with a heavy vehicle and big tires can cause the forging to bend in at the top, resulting in high negative camber. While not catastrophic, it does lead to your tires wearing out quickly along the inside edge and alignment issues which can make the steering a little twitchy. Bending the tubes at the differential, however, can lead to catastrophic failure. In other words, the axle falls apart and you're getting towed home.

When the axles in our '11 JK started to smile a little (the rear axle was even smiling some) we got to talking about how to fix it. There are numerous ways we could have gone. Several companies make inner-C gussets, trusses, and sleeves for the axletubes. We could have chosen any of these and had our axle straightened and strengthened. We also talked about finding an old 44 and beefing it up to Dana 60 standards, using off-the-shelf parts only—nothing custom. During the conversations, we kept coming back around to what the inherent strengths of our Rubicon's factory front axle were, though. It has that thick-cut ring gear and the oversized pinion shaft. Then the RockJock 44 housing from Currie Enterprises caught our eye.

Built to JK specifications, the Currie RockJock 44 housing would allow us to keep the strength of that heavier gearset, while getting a heavy-wall axletube, heavier center section, and much heavier end forgings. We decided on a 4.88:1 gear ratio to help turn our 37-inch tires, with ARB air lockers for traction duties. The beauty of selectable lockers, like the ARBs, is that you get all the advantages of a full spool off-road, while keeping the on-road manners of an open differential.

Revolution Gear and Axle provided us with everything else we needed to complete the axles. We got gearsets made from 8620 steel forgings, 35-spline axleshafts made from 4340 cromoly steel, and the setup kits, all of which are American made. As compared to the factory axleshafts, which are just under 1 3/8-inch diameter with 30-spline ends (rear 'shafts are 32-spline), the Revolution shafts are a full 1 1/2-inch diameter with 35-splines. They still use the larger 1350 U-joints, which then drop back down to 32-splines at the outer stub. The reason for this is that the unit-bearing can't take anything bigger. To open up the unit-bearing splines large enough to accept a 35-spline outer stub would weaken it to an unacceptable degree. Oh well, you can't have everything. All in all, we think we did fairly well in getting a Dana 44 that's nearly up to one-ton strength. It's certainly strong enough for just about anything we're going to throw at it with our JK.

01 There's a lot that goes into the housings of these differentials. Having worked as a heavy equipment and truck mechanic, I've done most jobs on a vehicle—engine rebuilds, several transmission rebuilds, lots of hydraulic system repairs, etc. For some reason, differentials just baffle me. It was a good thing to have the experts at Currie Enterprises put this together.

02 These ball-joints from Synergy Manufacturing are light years better than the factory ones. The factory ball-joints use a nylon liner inside and are not able to be greased. Synergy made these with a bronze and graphite cup, a hardened steel ball, and then added grease zerks. This makes for a much tighter joint and vastly improved handling and wear, especially when running bigger tires.

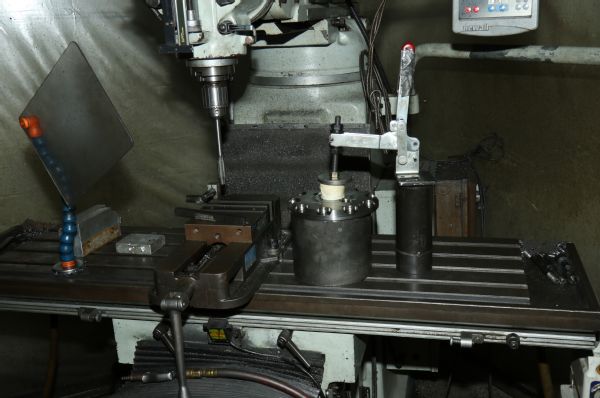

03 One of the nice things about having this job professionally installed is having the tools and equipment to do things properly. The bolt holes in the ARB carrier are too small for the JK-spec ring-gear bolts. Sure, reaming these out could be done by hand, but this Bridgeport knee-mill just makes things so nice. Hmm, I think I see an open space in the corner of the garage.

04 A small die grinder and a carbide burr are all that's needed to get this done. Well, that and a little experience. The bearing cap needs to have a notch ground into it so the air line can pass through without trouble. Where the experience comes in is knowing how much to grind without severely weakening the cap. When in doubt, it's always easier to go back and grind a little more.

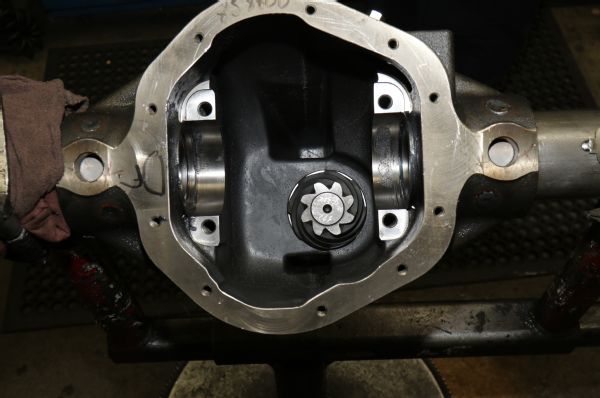

05 The center section Currie uses on its RockJock housings is immense compared to the factory JK Dana NG 44. With walls nearly an inch thick, the RockJock can withstand some heavy abuse. The only thing we miss is a drain plug. While it's not a bad idea to pull the cover and take a look at the insides while changing the oil, we personally don't want to have to reseal it at every oil change.

06 One of those great mysteries of life—well, of the Jeep world at least—is who thought it was a good idea to build a differential cover out of “tin-foil.” It's not really, but it sure looks like it. The Currie cast-iron cover is a huge improvement over the factory cover. It's about a 1/2-inch thick, with recessed holes to protect the bolt heads. The dipstick is a nice touch, making it easier and cleaner to check the gear-oil level.

07 Two of the three ports here are self-explanatory. The brass nipple is for the vent line; the other nipple is for the locker air line. Less self-evident is the large plug with the hole next to it. That plug covers the hole where the wiring goes through if we were reusing the factory electric locker. We'll have to pull the bolt out of the factory housing and use it to plug that hole.

08 The rear brake rotors and parking brake hardware were some of the parts we decided not to reuse. Ours were pretty well worn out already, so we replaced them. Considering how much better the parking brake works now, it was well worth it. We don't have to hope and pray every time we park on a hill anymore.

09 After 90,000 miles, the factory bushings were toast. The Johnny Joints we replaced them with helped to tighten up the suspension. They use a precision-machined steel ball inside a urethane bushing. Along with being impervious to weather, they are greaseable and allow for up to 30 degrees of unrestricted movement. Standard heim joints only allow for about 22 degrees.

10 Swapping an axle out really isn't that difficult. With some basic tools, a driveway, and some help, you may be able to swap them out over a weekend. Air tools do make things go faster, though. We took the opportunity to check everything out under the vehicle for wear and loose bolts. When you're this deep into it, it only makes sense to go over everything.

11 Sometimes when all the right tools are just not enough, you need a little creativity. We tried pickle forks, ball-joint pullers, C-clamps, and hammers—the upper ball joint just did not want to release from the knuckle. We finally resorted to our trusty reciprocating saw and cut the stud off. It was a lot easier to get the rest of the stud out with the knuckle clamped in a vise.

12 The Currie Currectlync steering is made from heavy-duty 1 5/8-inch heat-treated tube used for the links, with 1 1/4-inch forged-steel rod ends. Because they feature a threaded-in tie-rod-end cartridge (identical at all four points), the rod ends can be rebuilt. You just unscrew the bad joint, thread in a new one, and you're done.

13 The size of the Currie links is amazing when compared to the factory parts. The factory 1 3/8-inch tube just isn't up to the task of any serious off-road work with large tires. Our tie rod and draglink both had pretty good bows in them. We noticed that steering feel was much improved in our JK after the swap.

14 The Currectlync steering system is a direct bolt-in replacement for the factory parts. No special tools or machine work is necessary. The only issue we had was that the size of the knuckles pushed the dust shield into the brake rotors. A little trimming with a die grinder on the dust shield took care of that problem.

15 Why the factory rod-ends are not greaseable is a mystery. Whatever the case may be, Currie rectified that with its steering kit. All four rod-ends have grease zerks in them. A few pumps is all it takes, but those few pumps help prolong the life of the rod-end by a large margin.

16 The Currectlync steering includes the brackets to reuse the factory-style steering stabilizer. Since our 2011 JK already had a Fox ATS stabilizer on it, we didn't need the brackets. We did have to buy a new clamp for it, however, as the standard clamp is for a 1 3/8-inch tube.

17 Along with needing air for our lockers, we wanted to be able to air up our tires and possibly run air tools. We decided on ARB's CKMTA-12 twin compressor with the air-up kit. It inflates our 37-inch tires from 10 to 25 psi in just less than two minutes. We haven't decided on a tank yet, but we shouldn't have any problem running a few air tools.

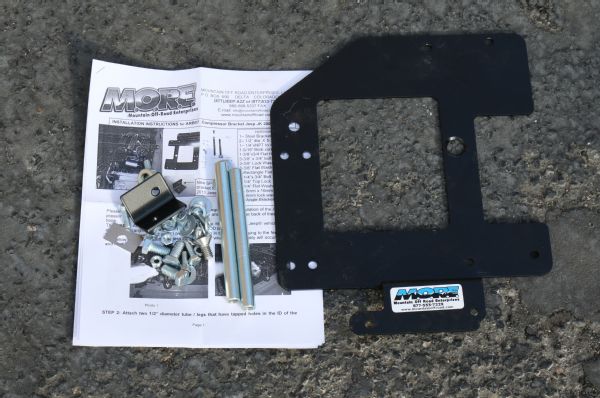

18 To mount the compressor, we used a part from Mountain Off-Road Enterprises (M.O.R.E.). It was a simple install and went in nicely. The only thing we aren't fond of is how it mounted to the plastic against the fender. We haven't had any problems with it yet and don't really foresee any, but we do think that it could use a more solid point on that side than what is basically a wiring harness cover.

19 It was a tight fit, but the M.O.R.E. compressor mount worked perfectly. It does make it a little difficult getting to the brake reservoir, but the mount is solid. When you hook up the air lines, remember to always use Teflon tape on threaded fittings. We decided to use gas-line-rated tape (yellow) as it's slightly thicker and should help with vibration, as well as making a tighter seal.

20 Our sPOD was full, we had already removed the factory electric-disconnect anti-sway bar, and now the factory lockers were going away as well. Because we no longer needed the factory switch panel, we thought this would be a neat place to install the air pump switches. A bit of trimming with a razor knife made room for them. Right next to the brake master cylinder is a hole in the firewall where we pulled the ARB-provided wiring harness through before assembling the plugs on the end.

21 Our JK's maiden voyage, with its new steering and axles, was to go recover a broken-down Jeep. The 4.88 gears made a huge difference both on- and off-road compared to the factory 4.10 gears with the 37-inch tires. We did find a need to reroute the air lines, though. We put them a little too close to the exhaust, and while it didn't melt the tubing, the heat did melt the loom the tubing was in. It wasn't a huge deal, but for long-term reliability, they need to be moved.

PhotosView Slideshow

PhotosView Slideshow