Sean P. Holman

Contributor

Sean P. Holman

Contributor

One of the most intriguing new axle options on the market is the Currie F9, a fabricated 9-inch drop-out axle that boasts strength, quality, and style. Each Currie F9 is fabricated from scratch with precision and can be custom ordered for any application.

Why a 9-inch over a Dana axle? The F9 is stronger than a standard Dana 44 and lighter than a Dana 60, while still offering excellent ground clearance at all pinion angles. And with a drop-out center section, customers can use high- or low-pinion third members.

The F9 fabbed housing far surpasses the strength of stamped 9-inch housings and features a 3/16-inch-thick Hi-Form 50 steel body with a 3/8-inch-thick Hi-Form 50 steel third member mounting surface. It is sized to accept specially machined 3- or 31/4-inch diameter axletubes with a 1/4-inch wall thickness. These machined axletubes lock the tubes to the housing during production, where they are welded on all sides for strength. As part of the quality control process, all welds are pressure tested against leaks. Back brace kits are also available for customers requiring the ultimate in strength.

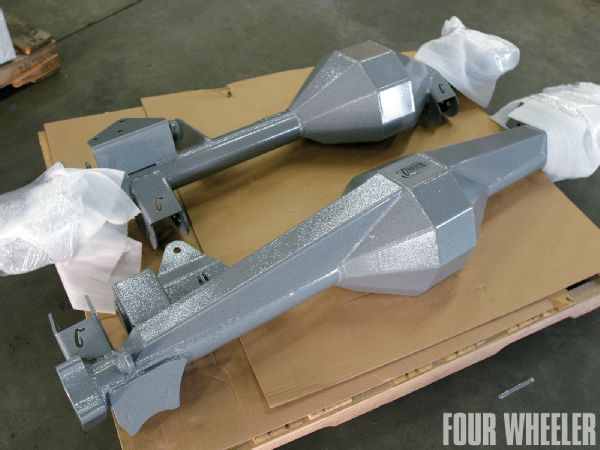

This customer chose front and rear F9s for his JK. The rear axle has the optional back brace added to it and these axles were powdercoated prior to assembly. Because of their construction, the F9 is very bracket friendly, enabling brackets (or bracing) to be welded anywhere on the housing.

This customer chose front and rear F9s for his JK. The rear axle has the optional back brace added to it and these axles were powdercoated prior to assembly. Because of their construction, the F9 is very bracket friendly, enabling brackets (or bracing) to be welded anywhere on the housing.

For those looking for a direct replacement solution, the F9 is available from Currie in ready-to-bolt-on form for the Jeep Wrangler JK and TJ. The JK axles are 66 inches wide and come complete with Currie's heavy-duty JK brackets, the 3-inch axletubes, beefier axle bearings, and accept all of the factory disc brake hardware, as well as ABS and ESP sensors. In addition, they also come with Currie's 35-spline rear axleshafts (35-spline fronts are an option), which are dual drilled to accept either the stock 5 on 5-inch bolt-pattern or the more common 5 on 51/2-inch pattern. Axles feature wheel studs, ABS tone rings, and axle bearings pressed on, as well as the bearing retainer plates. When ordering an F9 JK axle, the only part needed to complete the assembly is your choice of a high- or low-pinion third member.

We were recently invited to document the assembly of Currie's F9 axles at Off Road Evolution in Fullerton, California, where a customer's Jeep was undergoing a radical axlectomy. With the stock axles headed out to the salvage pile, the owner of this JK chose front and rear Currie F9s. These F9 housings utilize Off Road Evolution brackets and were powdercoated prior to our install. Check out what goes in to assembling the Currie F9 axles.

The JK F9 comes with Currie's heavy-duty JK suspension brackets, making direct bolt-in installation a breeze with most suspension systems.

The JK F9 comes with Currie's heavy-duty JK suspension brackets, making direct bolt-in installation a breeze with most suspension systems.

What's It Cost?

As of this writing, Currie has the standard front JK F9 that reuses the factory knuckles listed for $3,499.95 and the standard rear JK F9 listed for $1,899.95. Buyers can opt to beef the axle housing even further with the additional of the back brace, or choose other options, such as the 35 spline Extreme Duty axle upgrade or 1-ton F9 front housings at additional cost. Remember that all F9 housings will require high- or low-pinion third members to be complete.

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow