Verne Simons

Senior Editor, Jp

Verne Simons

Senior Editor, Jp

For years, old-school Jeepers have been collecting, coveting, and adapting granny-geared transmissions into their Jeeps. In this modern day of computer-aided design and 65-75 mph speed limits, why would anyone want an old clunky tow-truck granny-geared four-speed transmission in their Jeep? Well, in technical off-road driving, uber-low gearing never gets old. Sure, you could toss in a 4:1 gearset in the transfer case to the same end, but then you create a rather large gap between 4-Hi and 4-Lo, making high-range too tall for use in the fast stuff and low range so low that you can’t create any wheel speed. One solution is to go backwards in time and grab a granny-geared four-speed. We’ve gone out of our way to keep our ’97 four-banger TJ, sometimes known as the Shrink Ray TJ, relatively small and lightweight. However, with the stock AX-5 trans, low gearing was lacking with its unremarkable 3.92:1 First gear. At the same time, with 35-inch tires and 4.88 gears, Overdrive was basically useless unless running at speed downhill or on a perfectly level road. When synchros in our relatively lightweight AX-5 transmission started to allow a little grinding on quick shifts, we started looking for another gearbox to row the gears. Over the years, we’ve heard rumor of a combination of parts that would allow us to bolt our 2.5L AMC four-cylinder to old-school granny boxes like the SM420 and SM465. With a little research, we decided this might be the best course of action for us. Follow along as we cover the details of swapping a good ol’ granny box behind one of Jeep’s most common four-bangers.

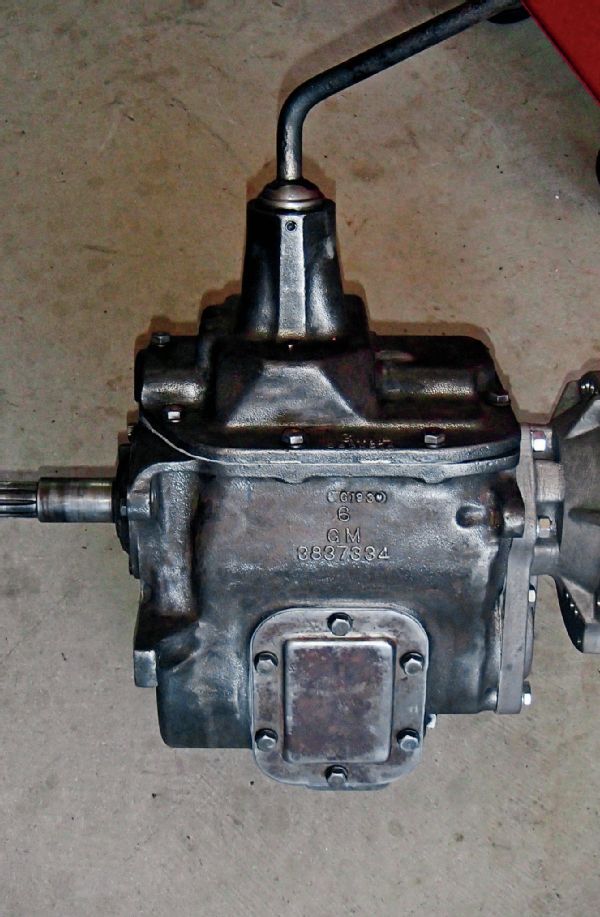

The SM420 is an old rockcrawling secret. The 7.05:1 First gear is one of the lowest granny gears out there. These transmissions are fairly old, with production in GM trucks ranging from 1947 to 1967, although some military vehicles still used them into the ’80s. You can still find a good SM420, although you will have to spend some time looking. The easiest way to identify them is with their cast iron case, top cover, and also the unique reverse idler bulge on the passenger side. Our SM420 came out of a ’64 Chevy long-bed truck (shown here with the Novak NP231 adapter installed). These transmissions shift like they came out of a bread truck or a tow truck, because that’s where they are from. If you need to shift quickly or make passes at the local track, this transmission is probably not what you want. That said, the low gearing is amazing for technical rockcrawling.

Another key part to this conversion is finding the right bellhousing. AMC’s 2.5L four-cylinders share the engine bolt pattern with GM 60-degree V-6s. That’s the same as the 2.8L V-6 most frequently found in S-series trucks from ’84 to ’90. We found our bellhousing at the junkyard (Novak recommends GM PN 15679692; ours was GM PN 15596765). This bell will bolt directly to the AMC engine and can be modified slightly to fit the GM Muncie/Saginaw four-bolt transmission pattern. We had to drill and cut on the bell in a few spots as well as use parts from Novak Conversions for the AMC four’s crank-position sensor. We also grabbed the clutch fork, slave cylinder, and slave cylinder hose from the S-10.

One modification necessary is to drill out the threads of the lower two holes of the bellhousing. You can then use graded cap-head bolts to secure the bellhousing to the transmission.

We also had to cut down this boss so the Novak Conversions crank-position sensor bracket would fit. You can have this boss machined at a machine shop if you want. We used a cut-off wheel in a grinder. If you do that, just be sure that the surface is nice and true to the face of the bellhousing.

Do as we say, not as we do. Here is the boss trimmed down for the sensor, Novak sensor bracket, and spacers (included in the sensor bracket kit). Please note that we are holding the sensor upside down in this image, while the bracket and spacers are in the correct place. The part has to be flipped so that the sensor is mounted towards the face of the bell rather than the position shown. We figured this out once the Jeep was all bolted back together and would crank, but not run. Oops. Well, to err is human. We hogged out the hole with a burr and a grinder, flipped the sensor, and the Jeep fired right up.

You also have to notch this ear for the lower bolt on the cast-iron case of the SM420 for clearance for the S-10 slave cylinder. There is also a small area of the bell at the front of the transmission near some vents that needs to be notched to mate flush with the transmission.

A gear reduction starter is also required because the nose cone and nose bearing on the factory Jeep starter will interfere with the S-10 bellhousing. Even with the Powermaster starter, we had to grind the bellhousing a touch for clearance of the bendix gear when extended to engage the flywheel. The Powermaster starter (PN 9633) has 4.4:1 gear ratio and produces 180 lb-ft of torque. That should help with those times when we have to start the Jeep in gear the trail.

Because of the much lower gear ratio of the SM420, Novak Conversions recommended that we upgrade our TJ’s NP231 to 23-spline from the weaker original 21-spline. Novak also supplied us with the adapter kit (PN 421) to mate the SM420 and our now 23-spline NP231. Many of the things we’ve done here also apply to the SM465 transmission, but that transmission requires more work to install with more grinding for clearance, has a less desirable Granny gear at, 6.55:1, and weighs a whopping 175 pounds (as opposed to the SM420’s 135 pounds and the AX-5’s 75-80 pounds).

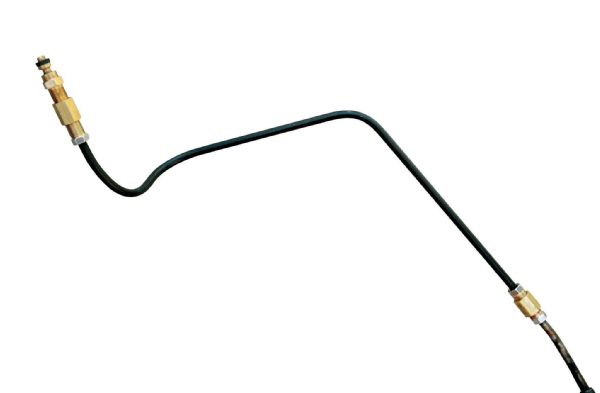

Novak also supplied us with a special brass hydraulic clutch release line adapter for a TJ master cylinder (PN HCA-1; there is also one for YJs). We used it along with the S-10 hydraulic line and a 1⁄4-inch hard line with double-flared ends. We cut and flared the S-10’s line and added in a brass junction to connect the two. You will also need a few more pieces and Novak has a kit (PN B150GM) that includes a specially machined pivot ball, crank-position sensor bracket and hardware, and pilot bushing. We also grabbed a brand-new version of the S-10 clutch fork from our local auto parts house.

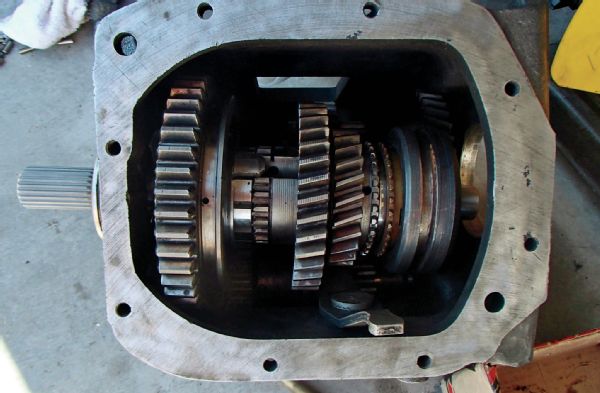

The Novak Conversions adapter is only part of the formula to getting our SM420 together with our now 23-spline NP231. It’s also necessary to install a new main shaft in the transmission with a 23-spline output. If there is any question about the state of the internals of your SM420, now is the time to rebuild it. Many new parts are available from Novak, as are rebuild kits. Our SM420’s synchros looked great and the bearings felt as smooth as new, but we did replace the seals in the transmission since the originals were dry and brittle.

Centerforce sent us a pressure plate for the 2.5L ’97 TJ to match the factory flywheel. For the clutch, we used a 91⁄8-inch diameter clutch with a 10-spline, 11⁄8-inch shaft (Centerforce PN 383824) to work with the input shaft of the SM420. We also used a throwout bearing from Centerforce (PN N1086) with the aforementioned stock replacement S-10 clutch fork.

Swapping to the SM420 means that you’ll need a slightly shorter front driveshaft and a slightly longer rear driveshaft as the transmission and adapter are a few inches shorter than an AX-5. Our TJ already had a slip-yoke eliminator on the NP231 and a rear Tom Wood’s Custom Drive Shaft. Tom Wood’s built us a new shorter front driveshaft, and the company was able to re-tube and lengthen the rear shaft they built for us about a year ago. Now we know that all that gear-multiplied torque will make it from the SM420 through the T-case and down to the axles.