Ali Mansour

Brand Manager, 4WD & Sport Utility

Ali Mansour

Brand Manager, 4WD & Sport Utility

When it comes to upgrading the rear axle in your Jeep Wrangler JK, there is no shortage of aftermarket options. Virtually all aftermarket rear axles come with suspension brackets, brakes, and even appropriations for tone rings, so everything can function as the factory intended. While we are grateful that these options exist, the biggest drawback to these “bolt-in” axles is that they come at a hefty price.

Last month, we took you through the process of building our junkyard-sourced high-pinion Dana 60 front axle, which we plucked from under a ’02 Ford Super Duty. This month, we are moving out back to install the Sterling 10.5 inch rear axle that we grabbed from under the same wrecked F-350. Using a ’07 Jeep Wrangler Unlimited as our builder-base, we have some leeway when it comes to what the Jeep will actually require to function normally (well, mostly normal).

Since most late-model Sterling 10.5 inch rear axles were fit with an 8-on-170 metric bolt pattern, it makes them less desirable to most eight-lug axle builders. With our front axle sharing the same metric bolt pattern, this is no concern for us. Just as with the 14-bolt rear axle, the Sterling 10.5 rear is plentiful and cheap. Given both the Sterling and 14-bolt can be had in a full-float configuration; each is perfect for supporting the often-portly Unlimited JK platform.

Speaking of the 14-bolt, it was actually our first choice when we originally laid out the idea for the swap. This wasn’t due to a major strength difference between the two full-float rear axles, but more to the fact that Torq Motorsports (torqaxle.com) actually offers a kit that allows you to fit the 14-bolt with tone rings. Ultimately, we decided that the Sterling was still a better low-buck option for guys looking to place 1-ton axles under a JK on the cheap. But, there is a catch.

Going with the Sterling 10.5 axle meant we would not have rear tone rings. Despite an individual working on a conversion to outfit the Sterling rear with tone rings that could work with the stock JK sensors, it wasn’t finished in time for the article. This means we will have a few lights on the dash and no stability control or ABS. For our ’07, this isn’t a big deal. Since we fit the front with custom unit bearings from Currie, we have a working speedometer and no check engine light.

To some, this will be a deal breaker. On the ’12-current models, running without sensors isn’t an option. We will break down how everything works and fit under the JK in next month’s issue, but for now, we’re going to focus on getting the full-float rear axle bolted in place. To see the details you missed in a previous article, be sure to check us out on the web at fourwheeler.com.

Our donor axle came under a ’02 Ford Super Duty. The WMS of our Sterling 10.5 axle is 68¾ inches, roughly three inches wider than the stock JK rear axle. By comparison, a 14-bolt rear axle can range from 63-73 inches. Finding the right width for the JK can take a bit of work. Once the stock spring and shock mounts were torched off of the axle, we cleaned the axletubes with a grinder. With both axles set on jackstands, we measure the correct placement of the axle brackets.

For axle brackets, we went with Currie Enterprises complete JK axle bracket kit. The Currie bracket kit offers a range of shock, track bar, and control arm mounting holes. The 3⁄16-inch steel set was easily adapted to the axle and burned in using a Miller MIG welder. Since our Jeep is equipped with an EVO Manufacturing EVO-Lever rear suspension, we didn’t need some of the included brackets.

The full-float hub is what makes this swap worth the trouble. While the Unlimited JK may start off a modest 4,300 pounds, it doesn’t take much for it to add on serious weight. Since the Sterling’s full-float hub is designed to take the weight and abuse of a heavy 1-ton truck, it should have no trouble supporting the JK. Since it’s equipped with the same metric 8-on-170 bolt pattern as our front axle, no machining or wheel adapters are needed.

If you’re concerned about the Sterling’s stock axleshafts, don’t be; 35-spline 1½-inch shafts were used from the factory. While the 14-bolt also has 1½-inch shafts, they only have a 30-spline count.

The aftermarket is a bit less supportive for the Sterling than the 14-bolt, but we had no trouble finding a set of 5.38 gears for our 10.5-inch rear axle. One interesting thing we found is that despite the 10.5 having a larger differential bearing set over the Sterling 10.25, the ring-and-pinions, along with the differential carriers, are interchangeable.

One upgrade that we couldn’t be without was a locker. With our JK seeing plenty of on-road time, we wanted something that would be unnoticeable on the street, but 100-percent effective in the dirt. This balance was achieved by installing an ARB Air Locker. ARB uses a patented two-piece case design with forged internal gears. While on the street, the locker works as an open diff, but when engaged, it becomes an ultra-strong full-carrier spool.

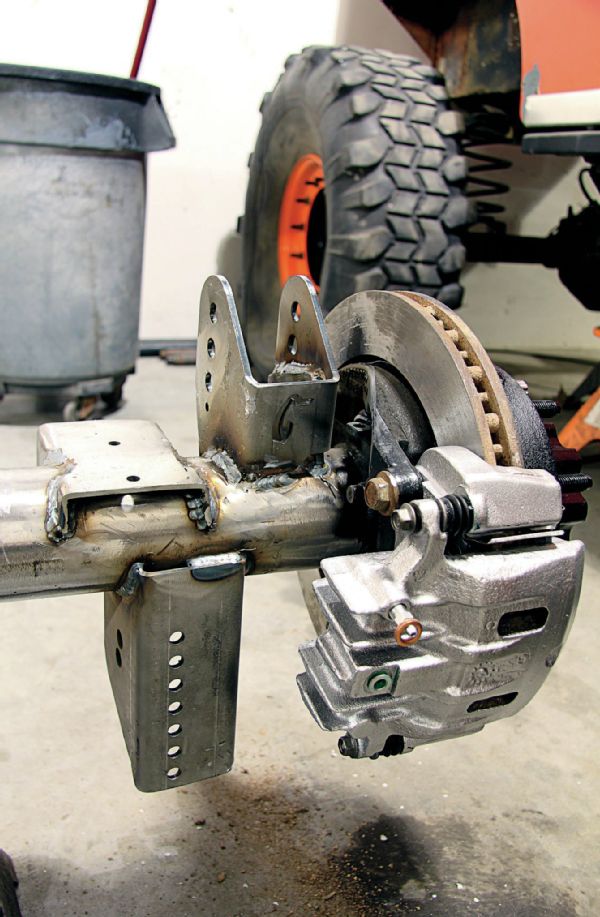

A major plus of the late-model Sterling axle is that it comes with disc brakes. We were able to reuse our aftermarket brake lines and the stock JK e-brake cables were easily adapted.

The Sterling in stock form is more than up to running our much larger than stock tires, and we’re excited to get the entire 1-ton package complete. Another bonus of the Sterling over the 14-bolt is that the Sterling offers 1¼-inch more ground clearance. That might not sound like much, but it’s enough to make a difference off-road.