John Cappa

Former Editor, Four Wheeler

John Cappa

Former Editor, Four Wheeler

With nearly 50,000 on- and off-road miles on our '07 Wrangler Rubicon you could say we know it pretty well.

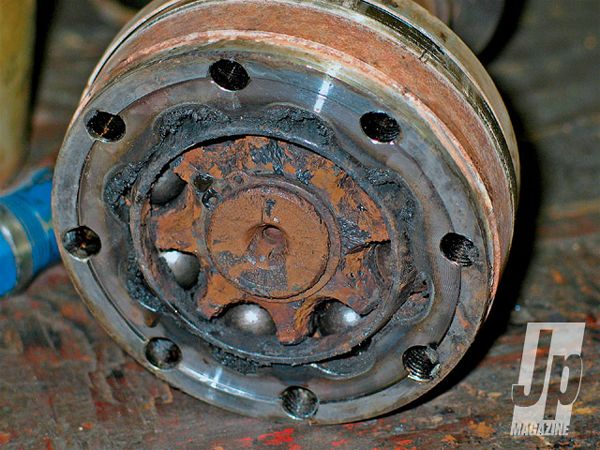

As somewhat expected, around 5,000 miles after lifting our two-door JK 4 inches we smelled burning grease and heard a whirring coming from the underside. A quick inspection revealed the protective boot on the rear driveshaft had fragged. The CV joint had ejected all of its grease and it was just about ready to go molten. In all truthfulness the stock rear driveshaft lasted a little longer than we thought it would. Anyway, we removed the rear driveshaft, put the T-case into 4-Hi, and limped the Jeep home on the front driveshaft to order and install some much-needed upgrades from J.E. Reel Drive Line Specialists and Rubicon Express.

If you plan on lifting your two-door JK, it's best to put a J.E. Reel U-jointed rear driveshaft on the lift kit shopping list. The longer four-door (Unlimited) model can get away with the stock driveshaft for a while, but we'd still consider the upgrade mandatory. The front driveshafts on two- and four-door JKs are identical. They are positioned so that they can survive with up to 4 inches of lift. However, since we were already under our Jeep we decided to replace ours with J.E. Reel components as well, just to be safe.