Jerrod Jones

Former Editor, Off Road

Jerrod Jones

Former Editor, Off Road

If you've been a reader for some time, you might remember our old '94 red Dodge appropriately named Jinxy. It came into the magazine getting a homebrewed coilover and long-link suspension,but it blew up a tranny driving home from the shop we built the suspension in. The tranny was rebuilt by JET but we sourced the wrong torque converter, and wasn't even broken in yet when we decided to go to town on the engine with some serious Mopar heads built by Dick Landy Industries, a Comp Cam, timing chain, roller rockers, a Mopar single-plane intake manifold, and 24-pound Holley injectors. Everything was buttoned up only to have the OBD-I ECU let us put about 100 miles on it before it went blaaahhh. The catalytic converter was breaking down and getting clogged due to too much fuel (you'd tear up when standing near it), and there were lean conditions at certain rpm that were heating up the engine as well. Obviously our ECU had no idea what to do, and we weren't at all making the power we should, and certainly not in a smooth band. So we needed a modified ECU. No biggy, right? Heck, people are building stand-alone engine controllers in their garages nowadays. We could certainly find something to run our engine...

Two years later we had learned that no one in the northern hemisphere wanted to bother with an OBD-I system, and certainly not a Chrysler one. Through one recommendation after another, we finally came across the Unichip engine-management system that can be adapted to almost any computer-controlled engine. The Unichip isn't a replacement engine controller or a handheld unit that reflashes the ECU, but instead a multi-processor-driven signal manipulator that goes inline between your engine and ECU. It not only can adjust fuel mapping and timing control, but can also manage any forced induction or nitrous systems to better control them and increase power past what you'd think possible. And for around $650, we think this little wonder is well worth it. Our Unichip Q-Plus is a universal unit that is hard-wired to our ECU and had to be programmed by The Dyno Shop in Santee, California. By the time you read this, the same microprocessor unit will be available from Unichip in a Plug 'N' Play module that adds power to stock gas engines on Jeep Wranglers and Toyota trucks as well as fullsize Fords and Chevys. But anything with inner engine mods like our Dodge will need the programmable Q-Plus unit and a skilled tuner like The Dyno Shop's Mark Macneil to set up the calibration.

The Unichip Q-Plus is an engine management system that originally was used for tuning Asian and European vehicles in South Africa. It can retard or advance timing, increase or decrease fuel, control water injection and nitrous, and complement forced-induction systems. You can also use it to set speed limiters, control shift lights, or change the boost on a factory turbo car. The unit is built to exceed OEM dependability standards, and will not reset should power be lost since the settings and parameters programmed into the Unichip are burned into the memory. It does not alter, reprogram, or replace any factory parameters in the factory engine ECU. The Plug 'N' Play Unichip units come with factory harnesses to plug in between your ECU and wiring harness and have a fixed calibration. There is an optional flex unit that can be acquired and is Bluetooth enabled so it can talk to a dash-mounted PDA, making it a live data display, or even select from five possible calibrations, some of which can be downloaded from Unichip's Web site. Stock or not, the Unichip will smooth out the engine's powerband, make more power, and give better fuel economy by ultimately increasing engine efficiency.

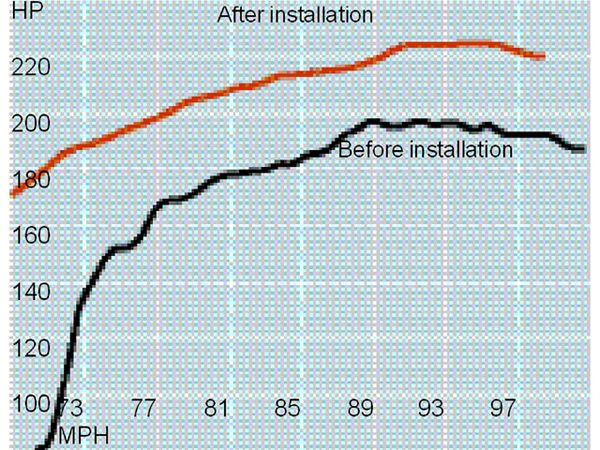

Once we had the new injectors in, Macneil set Jinxy on the dyno again and tried to squeeze a few extra horsepower from our engine. With the Unichip, Macneil can pull back fuel and lessen the intake into the engine, but he cannot increase flow capacity past what the maximum injector output is. The fuel changes made all the difference in the world to this truck, not only controlling proper fuel injection, but also smoothing out the power curve so it is steady throughout the rpm range. Thanks to the Unichip we made a little over 30 hp just by tuning the truck! Unfortunately, we found out that we could not really adjust the timing on our red Dodge thanks to the type of crank sensor it uses. Unichip has been notified and is working now on figuring out how to adjust the timing on our particular application. This was not a big concern, as the timing was not far off ideal, the engine still ran very well, and adjusting the timing would only have given us a couple of horsepower.

Horsepower Curves

Jinxy was on the dyno getting tuned when the driveshaft decided to leap from the truck. Apparently our little red Dodge started making some pretty good power, because the rear slip-yoke tailhousing broke all four ears off and separated itself from the transfer case, therefore pushing the driveshaft out as well, turning it loose on the undercarriage of the truck and the concrete around the dyno.

The truck was pulled back off the dyno, the NP231HD was pulled off the transmission, and it went straight to M.I.T. Drivetrain Specialists in El Cajon, California. Tech Andy Thomas took one look at our transfer case and just shook his head. Most of the transfer case was not hurt, only the rear tailhousing and output shaft were damaged. Thomas quickly gutted the 'case and had a JB Conversions fixed-yoke kit on the back of our transfer case in mere minutes. They even replaced our speedo gear to give us more accurate speedometer readings that we didn't have to compensate for.

We obviously needed a driveshaft now that we went from our slip-yoke design to a fixed rear transfer-case yoke. Thinking we might need a CV driveshaft and not sure what else, we called the folks at J.E. Reel in Pomona, California, to get their opinion. After discussing the amount of travel and what angles our driveshaft was sitting at, they determined that a CV 'shaft was not necessary, saving the cost of the build more than $100. Think of a CV (constant-velocity) joint on a driveshaft as a really expensive band-aid to deal with bad driveline angles, but with more parts to replace, and the tendency to wear out a bit faster than a non-CV driveshaft.