Here's the dilemma: For most forms of off-roading, you can't beat a short wheelbase. That's why Jeeps, early Broncos, Scouts, and the like are so popular. In the fullsize spectrum, that's also why Blazers, Jimmys, Ramchargers, and 1/2-ton trucks are the rage. But with any of the fullsizes, you get 1/2-ton running gear with tons (literally) to stress the axleshafts, gears, pinions, and driveshafts. These components have their own way of letting you know when you've asked too much.

It's no surprise that the most popular upgrade you can make to these vehicles is to swap in 3/4- or 1-ton axle assemblies. This fixes almost all the shortcomings of the lighter-duty axles, and in most cases the parts aren't that difficult to install.

The truck used for this conversion is a '76 GMC 1500 that came with a Dana 44 frontend and a 12-bolt rearend. Dana 44s were used until the mid '77s, when the 10-bolt frontend became 1/2-ton equipment. The 10-bolts replaced 12-bolts completely in 1983. Both 3/4- and 1-ton GM trucks used 14-bolt rears, so the real difference is in the front. Through the mid '77s, the 3/4-ton frontend was the same Dana 44 used under 1/2-tons. The rotor and hub were different and had the eight-lug wheel pattern. The 1-ton trucks used a Dana 60 up front, which is the ultimate in strength, but these are extremely pricey pieces. If your tire size or type of wheeling demands the strongest you can find, you'll want the 60.

The crew at Off Road Unlimited (ORU) does plenty of 3/4- and 1-ton axle upgrades in addition to all sorts of custom and bolt-on work on four-wheel drives. After discussing a few options, a 14-bolt was selected for the rear of this truck, while the original Dana 44 frontend would be converted to eight-lug. The first step was to strip the front axle of all of its steering, brakes, and axle components.

The crew at Off Road Unlimited (ORU) does plenty of 3/4- and 1-ton axle upgrades in addition to all sorts of custom and bolt-on work on four-wheel drives. After discussing a few options, a 14-bolt was selected for the rear of this truck, while the original Dana 44 frontend would be converted to eight-lug. The first step was to strip the front axle of all of its steering, brakes, and axle components.

The 14-bolt advantage is undeniable strength while the drawbacks include cost, lost ground clearance under the pumpkin, and weight. In addition to larger pieces and a pinion that's fully supported, eight-lug 14-bolts are full-floaters. This means that the weight of the vehicle is on the hubs instead of the axleshafts.

We've heard both ends of the spectrum regarding swapping a 1/2-ton to 3/4-ton gear: It's more expensive and difficult than you think versus it's an easy bolt-in. We went to Off Road Unlimited to find the truth and realized that, while it's not a 100 percent bolt-in procedure, it's not that intimidating either.

So What?

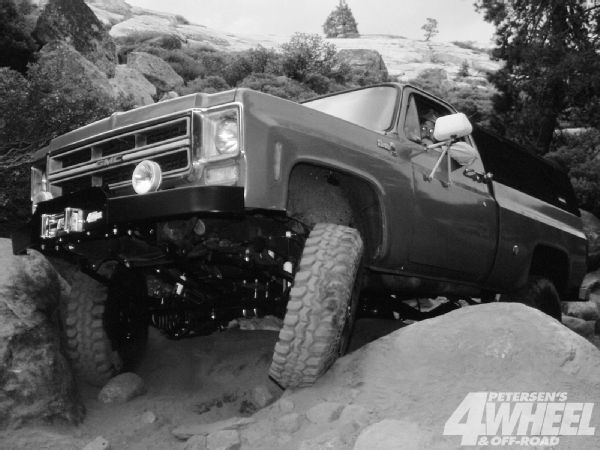

Everyone talks about swapping axles, and a few people actually do it, but how do you know for sure what it will really do for you? Inquiring minds wanted to know, so a mere 15 hours after this GMC had finished its axle surgery, it was on the Rubicon Trail. A tough trail by most four-wheeler's standards, it's even more challenging for a fullsize truck. It seemed like a great place to test a heavy-duty axle swap combined with the addition of lockers and gears.

The 4.56:1 gear ratio turned out to be perfect with the 36-inch Swampers, SM465 four-speed tranny, and half-worn-out 350 engine that kept on chugging all the way down to 400 rpm. The combination of a Detroit Locker in the rear and an ARB Air Locker in the front also proved to be a winner. Detroits are nearly indestructible, and both of these lockers survived the two days of abuse without even a whimper. In fact, we found the Detroit barely noticeable on the eight-hour drive to the trailhead and back home. The limited turning radius of this GMC made having the ability to turn off the front locker a true blessing. We engaged the Air Locker only when it was really necessary, which turned out to be less than a dozen times on the Rubicon. But when we needed it, the front locker saved us from resorting to throttle or a more precarious line.

The Swampers worked incredibly well. Even with snow and copious amounts of water and mud on the rocks, the tires slipped only a few times. The ride on the freeway was cush and not quite as deafening as nonradial Swampers, although it was still loud enough to remind you of your investment in rubber. The steel wheels were also the correct choice because they were unavoidably rubbed hard against rocks.

Finally, those fancy-looking aluminum diff covers survived the trip. The front one smacked some rocks with only a few scrape marks to show for it. The best summation of the testing is the fact that there was zero breakage.

PhotosView SlideshowThe Right Tires And Wheels

When you swap from five- or six-lug axles to eight-luggers, you must change wheels. Depending on your brake choices, you may also need to shift from 15-inch wheels to 16s or 16.5s, which also requires new tires. The truck used for this article had 15x8s with 33x12.50 tires before the axle swap. The front calipers and backing plates had been ground slightly for the 15s to fit, but the rear disc brakes required 16s for proper clearance.

Everything this truck needed to cure its wheel and tire dilemma was available through Tyres International. In addition to having an incredible selection, Tyres offers one-stop shopping and will deliver your tires mounted and balanced on your wheels. You can even order your lug nuts and locks from the company. This truck called for some serious meats on all-business wheels: 36x12.50R16 Super Swamper TSL radials on 16x10 American Racing type 767 steel wheels. The increase in tire height lifted the 14-bolt to maintain the ground clearance the truck had with the 12-bolt and 33s. The radial Swampers are a hair quieter on pavement and offer the same traction off-road as their steel-belted brethren.

PhotosView Slideshow