Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Tractors have them, dune buggies have them, and now more and more rockcrawlers and trail rigs have them. They are known as cutting brakes. Cutting brakes are a system of levers, switches, or pedals that allow you to lock up individual brakes in order to stop one wheel and then use the other wheels to drive the vehicle, thus pivoting around that locked wheel. The result is a tremendously tight turning radius, and they can be implemented in a variety of ways.

The best recipe for using cutting brakes requires selectable lockers and a transfer case that can engage the front or rear axle individually, but there are many other less expensive, yet just as rewarding setups. One thing to be extremely careful with is using cutting brakes at high speeds and on the street, as it can have deadly consequences. Read on about how some old-fashioned farm tech can make your crawler corner.

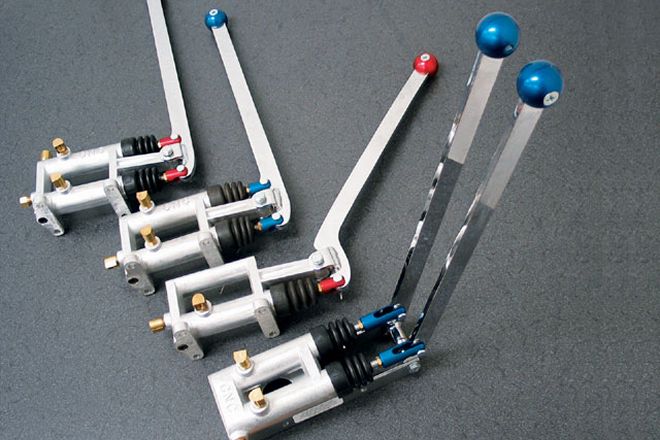

On many tractors the brake is divided into two pedals, one for the left rear wheel and one for the right rear wheel. If you need to stop, you step on both pedals at once. But if you want to turn really sharp, you step on one pedal and turn the steering wheel, and the tractor will spin around the wheel that is locked up. We found many different models of CNC cutting brakes at Poly Performance. This is the style found on most competition rock buggies and many dune buggies. They work by plumbing your brake lines into each lever's mini-master cylinder before it runs to each wheel brake or axle. Then when you want to lock it up, simply pull the lever and that wheel/slave cylinder locks the binders up. Then hold the lever, make your maneuver, let the lever go, and keep driving.