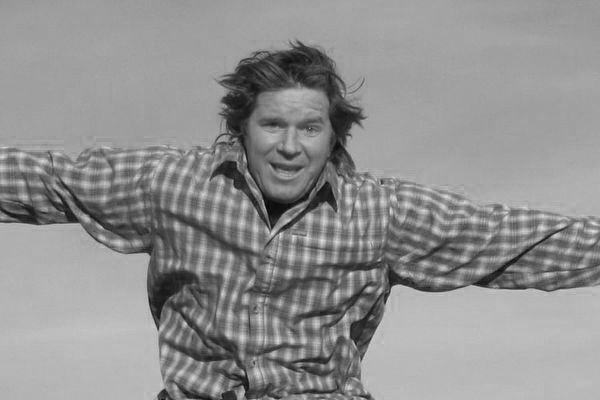

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Photographers:

The 4-Wheel & Off-Road Staff

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Photographers:

The 4-Wheel & Off-Road Staff

In the 4x4 business there are many opinions on wheels. Some want the nicest-looking wheel they can find with as much chrome as possible. Others couldn't care less about looks, as performance is their single goal. And then there are the guys that just want something between their axle and tires with whatever's cheapest filling the tire. On our tire test last month we examined a few sets of wheels and had both positive and negative results with each. Of course every manufacturer has certain goals with their wheels and we can respect that, but we've yet to come across the perfect wheel.

We are big fans of the Hutchinson Rock Monster bead locks, having run them on a few previous project vehicles. These double bead-lock wheels sandwich both the inner and outer bead and a rubber bead-lock insert between the two halves of the rim. Hutchinson also makes wheels for many military vehicles, so we decided to go with a set in Military Green for our Army Truck Project.

We are big fans of the Hutchinson Rock Monster bead locks, having run them on a few previous project vehicles. These double bead-lock wheels sandwich both the inner and outer bead and a rubber bead-lock insert between the two halves of the rim. Hutchinson also makes wheels for many military vehicles, so we decided to go with a set in Military Green for our Army Truck Project.

So what would be the perfect wheel? For us it would be a double bead lock to assure both the inner and outer tire bead stays seated even at single-digit pressures. It would be simple to mount tires on, preferably not requiring an hour-long wrestling match with each assembly. It would be strong but also lightweight; something around 30-35 pounds would be great since busting a kidney each time you swap your spare gets old. It would be pliable like steel so it can be beaten back into shape should it get bent, but light like aluminum. These mythical super wheels would have a well protected valve stem, but not so well protected that you can't get to them for airing up or down easily. And finally they would be available in a wide range of colors and finishes so whether you like the rugged matte black finish or fancy chrome, or just want your wheels to match your truck, anything is possible.

Oh and one last thing that is very, very important to us: You should never, ever need some special thin wall socket or extralong lug nut to mount your wheels on your truck; that is just plain wrong.