When it comes to home shop fabricating having the correct tool or tools is an extremely important factor for success. Sure, one may be able to create a component with a mallet and a block of wood, but the time spent would be excessive and the outcome more than likely less than stellar-especially in comparison to one fashioned using the right body hammer and a correctly shaped dolly.

Creating components from scratch versus purchasing parts from the aftermarket these days is a call one may make for a variety of reasons. Perhaps there's no source for a particular part, or maybe one just wants to personalize a component for a particular use or look. No matter the reason, having the right tool for the job is often an important factor in both energy/aggravation expended and successful completion of the task at hand.

Here we'll take a look at a small selection of affordable pipe and tubing benders that'll make our home shop fabrication chores a bit more time-, effort-, and results-friendly. Benders of the sort we'll take a look at allow us the ability to easily fabricate a myriad of custom items from small-diameter brake and fuel lines to crossmembers, reinforcements, mounting brackets, and even exhaust systems-all on our own. And just like the varied uses and applications for these creations, there are various types and sizes of bending apparatus, as well. But it doesn't end there, because not only are there different tubing and pipe benders to mull over, there is also a distinct difference between pipe and tubing, as well, which is something that until recently I wasn't quite sure of myself.

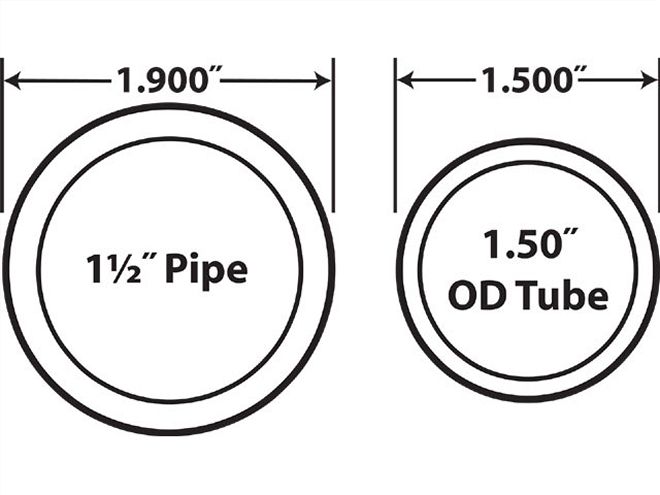

Here I wanted to start with a good example showing the difference between pipe and tube. On the left is a cross section of 1 1/2-inch pipe and on the right a cross section of 1 1/2-inch tubing. You can see that even though the pipe (L) is considered 1 1/2 inches, in reality its outside diameter or O.D. is 1.9 inches. Conversely, the 1 1/2-inch tubing (R) really does have an outside diameter of 1 1/2 inches. So there really is a physical difference between pipe and tubing, and as I said earlier, there is a real difference between pipe and tubing benders, as well.

Here I wanted to start with a good example showing the difference between pipe and tube. On the left is a cross section of 1 1/2-inch pipe and on the right a cross section of 1 1/2-inch tubing. You can see that even though the pipe (L) is considered 1 1/2 inches, in reality its outside diameter or O.D. is 1.9 inches. Conversely, the 1 1/2-inch tubing (R) really does have an outside diameter of 1 1/2 inches. So there really is a physical difference between pipe and tubing, and as I said earlier, there is a real difference between pipe and tubing benders, as well.

What is the difference between tubing and pipe you ask? Well, as one of my sources so eloquently put it, "pipe is for poop and tubing is for tufstuff," meaning pipe is used mainly as a conduit for material, like gasses, water, or, well, sewage, and tubing is for structural purposes. Not to say that there aren't situations where we may find a use for pipe in the hot rod realm (aside from structural uses like chassis, mind you).

What I learned is that pipe is sized by its inside diameter (or I.D.), versus tubing which is measured by its outside diameter (or O.D.). To confuse matters even more, the wall thickness of the pipe is described by the schedule of the pipe. Two common schedules are 40 and 80 (schedule 40 being heavy and 80 being extra heavy), with schedule 40 being by far the most common. The schedule 40 wall thickness is not a set dimension for all sizes of pipes though. 1-inch schedule 40 has a wall thickness of .133 inch and 2-inch schedule 40 a wall thickness of .154 inch, go figure. As I said earlier, pipe is sized by the inside diameter, so with this in mind, let's take a look at 2-inch pipe as an example and see what some of the differences are in scheduling. 2-inch schedule 10 pipe has an I.D. of 2.157 inches, 2-inch schedule 40 has an I.D. of 2.067 inches, and 2-inch schedule 80 has an I.D. of 1.939 inches-but the outside diameter or O.D. of 2-inch pipe is 2.375 inches for all three schedules-again, go figure. As a side note, pipe is commonly available in carbon steel in two types: continuous butt-weld and electric resistance welded or (ERW).

Tubing is available in many different types of materials and wall thicknesses, and best of all, tubing sizes actually make sense! Unlike pipe, tubing is sized by its outside diameter or O.D.; 1-inch tubing really does measure 1 inch on the outside (within a few thousandths of an inch, anyway). Tubing wall thicknesses are measured in gauges up to a point, and then convert to fractions of an inch. In fact, some wall thicknesses are even measured in millimeters. Outside diameters range from 1/8 inch and upward beyond 12 inches, and wall thicknesses range between 20 gauge (.035) and 2 inches thick. Tubing is also available in many types of materials, some including mild steel, steel alloys (4130), aluminum (6061, 6063, 2011, 3003, with various degrees of heat treating), brass, copper, stainless steel, as well as others. Tubing is also available in many types of drawing and forming processes, some including cold drawn seamless, butt-weld, ERW or electrical resistance welded, DOM or drawn over mandrel, hot finished seamless, and others.

Here is an example of a couple of the pipe benders I have on hand back in my home shop. Both have come in pretty handy during the course of countless projects and each one's capabilities have worked successfully in different situations. Though both came from the same source (Summit Racing) and see more than their fair share of use, the manual small-diameter bender seems to see a bit more when it comes to fabrication chores because of its ability to make sharper bends than the hydraulic bender.

Here is an example of a couple of the pipe benders I have on hand back in my home shop. Both have come in pretty handy during the course of countless projects and each one's capabilities have worked successfully in different situations. Though both came from the same source (Summit Racing) and see more than their fair share of use, the manual small-diameter bender seems to see a bit more when it comes to fabrication chores because of its ability to make sharper bends than the hydraulic bender.

These facts bring us to an important point. Seeing as there really is a physical difference between pipe and tubing, there is a real difference between pipe and tubing benders, as well. You see, the dies used for pipe benders will have radius channels which are larger in size than those used with tubing benders for the aforementioned reasons -2-inch tubing is actually 2 inches in diameter, and 2-inch pipe is actually 2.375 inches. This means that if you were to try and bend 2-inch tubing in a 2-inch die-equipped pipe bender the tubing would surely kink because the oversized pipe die would not provide full support around the O.D. of the tubing. And vice versa, a section of 2-inch pipe wouldn't even fit in a 2-inch tubing die because the pipe would be too large in diameter to fit the die.

See where we're going here? If you buy a pipe bender to bend up your next tubing project, you're gonna be disappointed when you find that your material keeps being kinked beyond use every time you try to form it-not good for your state of mind or the state of your fabrication aim, and not the fault of the bender itself, either.

All this said, let's take a look at a few of the more common types of home shop (read: affordable) pipe and tubing benders one might want to have on hand, and a bit more usable pipe and tubing information, as well.