Ken and Nick Smith of Hot Rod Works specialize in the rebuilding and updating of early Ford rearends. They can supply axle and brake conversions as well as quick-change center sections.

Ken and Nick Smith of Hot Rod Works specialize in the rebuilding and updating of early Ford rearends. They can supply axle and brake conversions as well as quick-change center sections.

Building and driving a traditional hot rod certainly isn't for everybody-after all, there are sacrifices involved. Putting one together takes time, money, and an infinite amount of patience looking for just the right parts. Then once your work of automotive art is on the road, the fact is, most of them have a few idiosyncrasies that have to be tolerated; it may not ride like a new car, there may even be a rattle or two, and if you've gotten home at least once thanks to the judicious use of duct tape or mechanic's wire, that's about par for the course. But for the true believer, the world just looks better from behind the wheel of a real hot rod, the faint odor of a warm Flathead is like perfume, and the sound of an early transmission under a load in Second gear is music to the ears-it's a sensory fest of sorts, a Disneyland ride for hot rodders.

While traditional hot rods certainly have a place in our heart, there's an old saying that goes, "Those who don't learn from history are doomed to repeat it." In hot rod terms, that simply means there's a reason lots of Flatheads and three-speeds were replaced by small-block Chevys and automatics. But today, thanks to top-quality parts and better lubricants, Henry's venerable V-8 can be made better than ever, slipping a contemporary five-speed in place of a fragile top loader is a simple task, and thanks to Ken and Nick Smith of Hot Rod Works, early Ford banjo rearends can be made better than ever.

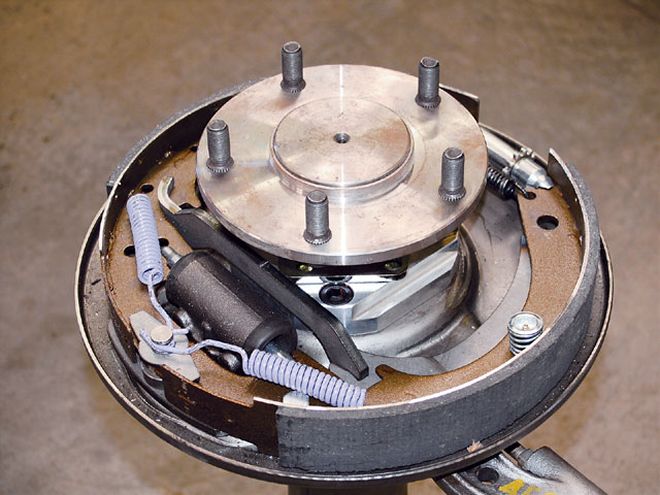

We stopped by Hot Rod Works and found an axle swap in progress. The brakes are '40 Lincoln reproductions in this case.

We stopped by Hot Rod Works and found an axle swap in progress. The brakes are '40 Lincoln reproductions in this case.

Like most things Ford did early on, the design of the rear axle was unique. Similar to the way most heavy truck rearends are still built today, the axleshafts did not support the weight of the car; instead, the wheel bearings ride on large journals that were actually part of the axlehousing. Consequently, the housing rather than the axle supported the weight of the car. But while that meant a Ford axle wouldn't usually fail from the pounding it had to endure due to the rough roads of the day, they still broke. The weak point was the tapered and keyed end where the axle attached to the hub, and if the torque of a stock engine could shear keys and twist off axle ends, imagine what a hopped-up Flattie can do.

While in most cases a broken axle isn't the end of the world, again, Ford's unique design comes into play. Early Ford axleshafts have an integral side gear that is part of the differential assembly, and it is that gear that holds the axles in the housing. In other words, if an early Ford axle breaks, there's nothing to keep it, and the wheel attached to it, in place. One of the most sobering experiences you can have is glancing in the outside rearview mirror and seeing a rear tire, and the remains of a broken axle, as they take off on their own.

Differences in the outer ends of the axles are obvious; the early Ford is tapered and has a keyway, and a nut on the threaded end of the shaft retains the hub that mounts the wheel. On the later axle, the wheel flange is integral.

Differences in the outer ends of the axles are obvious; the early Ford is tapered and has a keyway, and a nut on the threaded end of the shaft retains the hub that mounts the wheel. On the later axle, the wheel flange is integral.

As broken Ford axles were common, most racing organizations required some sort of retention system to keep the wheel in place if an axle broke. Some were as simple as clips that fit over the lips of the brake drums, then there were more elaborate safety hubs, and eventually late-style slide-in axle conversions were developed. The advantage to using the latter is that the bearing presses on the axle and is held in the housing by a retainer at its outer end. If an axle fails, it will just about always be on the inside of the bearing, so the retainer keeps the broken end, and the wheel, attached to the housing.

While the late-axle conversion is a natural for early Ford rears, the big problem has always been the differential side gears. Since the originals are integral with the axles, substitutes that accept slide-in axles must be a perfect match when other differential gears are necessary.

Over the years, a variety of differential side gears have been used to adapt late axles to early Ford rearends, but none fit perfectly, so some modification to them was always necessary-usually grinding down the outside diameter, hardly a precision operation. But thanks to Hot Rod Works, those days are over. As part of their axle conversion kits, they now offer gears designed specifically for the application. Machined from 8619H bearing-quality bar stock and heat-treated for strength and long life, they are patterned after the original 16-tooth Ford axle and accept 28-spline Ford-style slide-in axles.

The Hot Rod Works axle conversions are available in two forms: one that uses early Ford brakes, and the other uses late-Ford small bearing-style stoppers. In either case, the true weak links in the early Ford rearend are eliminated. It just goes to show you can have the best of both worlds-the strength and safety of contemporary axles with the traditional look of an early Ford rearend with no sacrifice involved.