E-mail your tech questions to us at [email protected] (include the words "What's Your Problem?" in the subject line) or fax them to 323/782-2223. All correspondence must be signed with the sender's real name (not a nickname or a screen name) and include the sender's hometown and state or province. While mail cannot be answered personally, Car Craft will publish as many letters and replies as space permits. Photos are welcome, but no materials will be returned.

Mopar Challenge

I'm 16 and have a '74 Dodge Challenger that I want to build, although I am on a budget. I bought a '73 model 400 block that has been bored 0.030-over along with a '78 440 out of a Dodge van, which is complete and even came with the 727 transmission. I want to use the 440 crank and build a stroker motor. The 400 did not come with any heads, and I was wondering if I could use the 440 heads. I know that they are low compression, but I thought about having them shaved. If I can use the 440 heads, which intake will I need to use, RB or B? I want to build the car as for street/strip use and would like to run mid-to-low-12s. Any help with cam, carb, intake, and so on would also be appreciated.

Kory Raines

Via the Internet

Building a stroked 400 Mopar using a 440 crank is a popular practice, though it does require a bit of specialized machine work and some custom parts. The 440 crank has larger mains than the 400 block, by nearly 11/44 inch, so either the crank main journals need to be cut down or the main saddles in the block have to be line-bored to the larger diameter. Most Mopar engine guys seem to favor line-boring the block, as they feel that too much material has to be removed from the cast crank, rather than the earlier 440's forged steel piece. Either way, you'll also have to use a big-block Chevy connecting rod with a custom piston, though some manufacturers are beginning to offer this application "off the shelf" due to the popularity of this combination. Check out Diamond Pistons for the slugs, and then look up Muscle Motors for complete kits. If you go this route, you'll wind up with a B-engine-based 452ci engine that will require a B-intake, since it will still be a low-deck engine. The 440 heads you have are actually the same castings that would have been used on a similar vintage 400 engine, so they'd work just fine on the 400, though you would need to calculate the compression ratio based on pistons you planned to use.

However, since you did mention that you were on a budget, frankly, you'd be better off simply building your 440-the extra 12 cubes aren't going to do that much for you. Enthusiasts often scoff at the later 440 engines like yours, though they're still perfectly acceptable for a street/strip type of car. The major drawbacks are that the blocks are based on a thin-wall casting and the crankshafts are cast iron rather than forged steel. However, if your block has not been over-bored, it should still be plenty strong, even after a 0.020-over rebuild. If you have doubts, have a machine shop sonic-check the bores to determine how much meat is still there. The cast crank is fine for your application as well. Building compression will be your biggest challenge, since your engine probably started with as low as 7.8:1. A problem facing those attempting to build 440s has been the availability of reasonably priced performance pistons, as most of the rebuilder slugs have super-low compression height in an effort to keep compression down. The classic approach for mild street engines has been to use a TRW (now marketed as Federal-Mogul) forged Six-Pak replacement piston, though these aren't cheap and they're heavy by today's standards for performance applications. However, Speed-Pro has recently introduced a hypereutectic version of a Six-Pak-type piston that is lighter and priced right. If it's anything like the hypereutectic Speed-Pros we've used in numerous small- and big-block builds in the recent past, the quality and consistency will be excellent. These pistons with your heads will easily boost the compression over 9:1, and probably closer to 10:1, depending on whether or not your block is decked and/or your heads are milled, and what type of head gasket is used. If you should find the need for an extra-thin head gasket to boost compression, Mopar Performance offers a steel-shim gasket for the B and RB engines (P4286754) that features a 0.020-inch compressed thickness.

Pingin' Imp

I have a '95 Chevy Impala SS that I've owned for a couple of years. The car runs strong, though lately it's developed a problem where it seems to detonate at part throttle. At first I thought it was because the engine was running a little too warm and perhaps my fuel wasn't up to snuff, but I've installed a cooler thermostat and have been running the best fuel I can get (91 octane around here), but even when the temp gauge shows a cool engine, the car will make the distinct pinging sound of detonation. I've heard lots of theories, some involving the EGR valve and others regarding an overly lean air/fuel mix. I really don't want to start swapping expensive parts if I don't have to, so what do you think my next move should be?

Tom MacIntire

Sonoma, CA

Some of the advice you're getting may be close to the mark, Tom. The LT1-powered Chevys use a knock sensor, so in theory, these engines shouldn't detonate since the computer should be pulling back the timing to eliminate the condition, then feeding the timing back in gradually. However, there are still a number of factors that can contribute to detonation on LT1 engines. The most likely culprit on a Caprice/Impala LT1 is the exhaust gas recirculation (EGR) valve. Although most American cars have been equipped with an EGR since the mid-'70s, for some reason, EGR failure seems fairly common on the Impala and Caprice. As the term implies, the EGR valve feeds exhaust gas back into the engine. The exhaust gas is basically inert, containing little or no fuel and oxygen, so it can't contribute to combustion. By injecting exhaust gas into the inlet air stream, combustion chamber temperatures are reduced. The purpose is to reduce NOX emission by creating a less potent burn. This obviously sounds like a major power-robber, but the EGR is only supposed to function under light part-throttle loads, when the engine doesn't need to make a lot of power. Most EGR valves, whether on carbureted or fuel-injected engines, are controlled with engine vacuum. The confusing part of diagnosing the EGR is that although it is activated with vacuum, which is highest at idle, the EGR should not be open at idle. On older carbureted engines, the vacuum line was usually connected to a ported vacuum source, so that at idle, the valve received no vacuum and remained closed. However, as soon as the throttle was opened, vacuum would be fed to the valve. When heavy engine loads are present, vacuum drops and the valve closes. On fuel-injected cars, an EGR control solenoid is usually employed to cut vacuum at idle via electronic controls.

The problem that can occur when an EGR valve malfunctions is that it will open too soon, or not close, usually because the internal spring is weak. This causes an overly lean fuel mixture, resulting in rough idle and stumbling under acceleration. However, if the EGR solenoid malfunctions, the valve will either receive vacuum at idle, again resulting in a rough idle, or it will never receive vacuum, often resulting in part-throttle engine detonation, since the engine's PCM is calibrated to account for the presence of exhaust gas in the combustion chamber under these conditions. When the exhaust gas isn't present, there is more air, and since the computer may not "see" this right away, the resulting lean air/fuel mix can lead to detonation. The LT1 is particularly susceptible to this since it has a relatively high compression ratio (10.1:1).

We mentioned the knock sensors that the LT1 uses (two: one in each bank, usually threaded into the holes originally intended for the block's water jacket drains), and these can cause detonation if a failure occurs. In this case, the PCM doesn't have any input regarding the spark knock, so the ignition timing remains aggressive, eventually causing detonation. This can occur even when only one sensor is bad, since the LT1 adjusts the ignition timing for every cylinder on every firing stroke. However, since you indicate that your Impala is not experiencing detonation under hard throttle conditions, the knock sensors are probably not the problem.

A Primer On Primer

I recently bought an '81 Malibu that had most of the bodywork already done by the previous owner, but it still needs a little body filler to make it straight. I am 15 and on a very tight budget ... like $180. I've already got the bondo and I'm going to do all the work along with my father and my uncle, but I need to know a few things. I have a spray gun and compressor, but what kind of primer would you recommend if I want to leave it in primer all winter, outside, with a car cover on it? I know I could use PPG DP90, but that's a little too expensive. Do you know anything cheaper, or a primer and paint combo that would be cheaper? What do you recommend that I do? Any suggestions would really help a car guy out.

Joey Litak

Detroit, MI

If you plan to leave the car outside over the winter, even if it's under a car cover, don't cheap out on the primer. Most primers are simply intended to provide a layer that will adhere to the metal, which the paint can then adhere to. As such, primers usually don't provide sealing, unless they specifically state this feature. This means that if you spray your bare-steel body with a typical inexpensive primer and then subject it to moisture, you can expect rust to begin forming before long. This will require you to sand the car back to steel and re-prime when it comes time to continue the project. A potentially worse situation can occur when the rust is just starting to form in the pores of the primer. It may not be obvious to the naked eye at this point, so you might continue with your paint job. Six months or so down the road, bubbles begin to form randomly throughout your paint job because you sprayed over the early stages of oxidation. Also, if you are using plastic body filler, you should make every effort to keep exposed areas of filler free of moisture, as most fillers will actually absorb moisture, which can later manifest itself in bubbling paint or rust spots beneath the finish.

The PPG DP90 primer you mentioned is actually an epoxy primer, and does offer sealing properties. It is an excellent product as it bonds strongly to steel and seals off the surface from external evils. It may be a little pricey, but it's probably worth it in your situation. There are other similar products on the market that offer sealing features, and some of these are less expensive. Check with a local paint and body supply warehouse-the bigger places usually offer cheaper alternatives to the name-brand stuff for economy-oriented shops.

A Well-Oiled Machine

I have a '70 Chevelle SS with an LS5 big-block. My car has been in the paint shop for two years, and I'm finally getting ready to start the engine soon and would like to know the best way to prime the lubrication system.

Ed Prince

Albany, NY

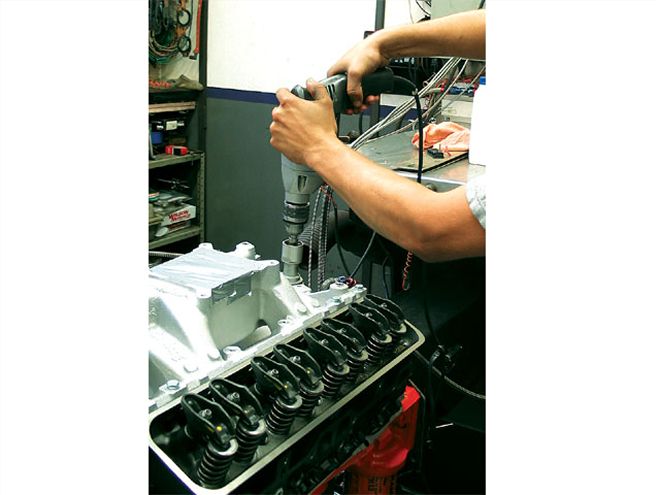

You simply need to pick up a priming tool and pump some fresh oil through the engine prior to firing it. The priming tool fits in place of the distributor but does not engage the camshaft drive gear. This allows you to spin the tool with a power drill, which in turn spins the oil pump, circulating lube throughout the engine without having to actually start it. When you hook up the drill and start to spin the priming tool, you should initially feel little or no load on the drill, but within the first few seconds, a pronounced drag should kick in, indicating that the oil pump has just developed pressure. The length of priming time seems to vary from one engine-builder to another; some spin it just long enough to generate pressure and fill the oil filter while others will spin the drill for another 30 seconds or so, then rotate the engine with a breaker bar and continue. Basically, if you prime the engine long enough to have fresh oil coming up through all 16 pushrods, you're ready to fire it up. The tool for Chevrolet is probably the easiest to find, and is available from many local auto parts stores and speed shops in addition to mail-order houses like Summit and Jegs, or you can make your own out of a discarded distributor.

Our Mistake?

Regarding your response in November's "What's Your Problem?" to the question about Ford distributor swapping, you are correct in your dissertation except for one minor point: The reader stated he has a 351M, as in Midland, commonly called 351 Modified. The 351M/400 series engines use a common distributor with the 429 and 460 big-blocks, and in fact, they have longer shafts than the small block 302s. What he needs to do is get a '75-'84, 302 Duraspark distributor. It will plug right into his old harness. This also answers the oil pump driveshaft problem. The 351 Windsor distributor is unique because of its 1.3-inch-taller deck height.

Ray Vaira

Ash Flat, AK

In case you haven't already been flooded with mail, the November issue of Car Craft has a mistake in the answer to "Distributor Discrepancy." He can't get the distributor to work with the oil pump shaft because the 302 uses a small-block distributor while the 351M uses a big-block distributor. He needs to find a 302 distributor from the late '70s/early '80s to keep the ignition from the '79 truck. Also, a 351W distributor won't work with a 302 because the block is taller, hence a longer distributor. Nobody walks on water; we all make mistakes.

Sean Perry

Via the Internet

In your November "What's Your Problem?" article, there was a question concerning the 302 distributor fitting into the 351M engine. There is no way that distributor will go in there! The 351M uses a larger hex and has a larger-diameter body (where it fits into the block). He needs a 302 distributor to fit the 302 block. He could just swap the innards from the 351 distributor to the 302 distributor.

Steve Wilks

Carrollton, TX

Thanks for all your input, but if we all go back and read that question and the response, you'll hopefully find that no one asked if a 351M distributor would fit into a 302, nor was any advice offered to attempt this. The question was whether an early 302 distributor will fit in an older 302. By the way, those of you who pointed out that the 351W distributor is taller than the 302 distributor need to take another look at both of those engines. Despite the fact that the 351W has a taller deck height, the distance between the cam gear and the distributor mounting pad is basically the same (check the photos). However, you are right that the distributor for the 351W is unique, though it's the cam gear that makes all the difference.