Thanks to the huge selection of aftermarket parts that are just a phone call away, building a trick truck that is safe and fun to drive is easier than ever. A great example of aftermarket components that just about every truck can benefit from are better brakes. With the wide variety of stoppers available, making your hauler come to a halt on the proverbial dime should be easy. The hard part can be picking the right parts from the array of individual pieces and complete kits that are out there. It can be confusing and somewhat intimidating so it's important to be well informed before you lay your cash on the counter.

Classic Performance Products offers a variety of brake components. This frame-mount kit for Chevys adapts a vacuum booster and aluminum dual master cylinder to the stock pedal. Manual master cylinder adapters are also available, as are remote reservoirs.

Classic Performance Products offers a variety of brake components. This frame-mount kit for Chevys adapts a vacuum booster and aluminum dual master cylinder to the stock pedal. Manual master cylinder adapters are also available, as are remote reservoirs.

Brake Basics

Brakes work on a simple principle we all learned as kids. When you fell on your butt and slid over an asphalt playground you came to a stop quickly; if you did it on ice the stop wasn't as immediate. How quickly you came to a stop had to do with the coefficient of friction between the stationary surface (the ground) and one that is moving (your butt). The friction is between the stationary brake pads or shoes and the rotating discs or drums and with your truck the more friction there is the better the brakes will perform.

Drum Brakes

For all practical purposes drum brakes can be broken up into two general categories: self-energizing and non self-energizing. An example of the latter can be found on '48-and-earlier Fords. With this design each brake shoe had a pivot point at the bottom and they operate independently of each other.

A more modern design, and one that is still in use today, is the self-energizing drum brake developed by Bendix. With this style of brake the shoes are hooked together at the bottom by a spring and adjuster and are held to the backing plate by a pin, spring, and retainer. Mounted this way they are free to move slightly on the backing plate. When self-energizing brakes are applied the front brake shoe makes contact with the revolving drum and tries to rotate with it, that movement is transferred through the adjuster to the rear shoe, pushing it into the drum with increased force. Self-energizing drum brakes are still commonly used, most often on the rear of trucks with discs on the front.

Firewall pedal assemblies are also available. This kit includes the firewall mount bracket with pedal assembly, 8-inch dual power booster, master cylinder, proportioning valve, and all mounting hardware.

Firewall pedal assemblies are also available. This kit includes the firewall mount bracket with pedal assembly, 8-inch dual power booster, master cylinder, proportioning valve, and all mounting hardware.

Disc Brakes

Heat is also the enemy of brakes. As the friction surfaces become hotter the coefficient of friction between the two is reduced and the brakes lose their effectiveness. The term that is often used to describe this is brake fade. If you've ever driven a truck down a steep grade and found it took more and more brake pedal pressure to slow it you've experienced brake fade.

When it comes to dissipating heat, disc brakes have a huge advantage over drums. As the caliper only covers a small part of a disc brake's friction surface, a large portion of the rotor is exposed to air, which keeps it relatively cool. With a drum brake most of the friction surface is in contact with the brake shoes, which leaves little surface area for cooling. Consequently, compared to discs, drum brakes get hotter faster and stay hotter longer. During hard or continuous use, this reduces their efficiency noticeably.

Another factor that allows disc brakes to function more effectively than drums is the wiping action inherent in their design. In wet conditions the brake pads tend to wipe water off the rotor, with drums, moisture can become trapped between the shoes and drum, which lowers the coefficient of friction considerably until the water is dispersed.

Calipers

There are three common types of calipers: fixed, sliding, and floating. Fixed calipers are mounted solidly to a mounting bracket with one, two, or more pistons per side to apply the pads. When multiple pistons are used on each side they are more or less in a row; consequently, the caliper can utilize a longer pad more effectively than a single-piston caliper. The combination of multiple pistons and large friction surfaces mean that fixed calipers can supply a tremendous amount of stopping power.

While fixed calipers are very effective, they do have a couple of minor shortcomings. First off, since there are pistons on both sides of the caliper, fluid must be delivered to both sides of the caliper. That means small external lines or well-sealed interior passages must be provided to connect the two halves. In either case that means that construction is more complicated and consequently, more expensive.

Want to keep your '63-72 Chevy's six-lug wheels while adding four-wheel disc brakes? CPP has several kits to do just that.

Want to keep your '63-72 Chevy's six-lug wheels while adding four-wheel disc brakes? CPP has several kits to do just that.

And while they perform very well, they are unforgiving of any runout in the rotor. If the rotor wobbles it will tend to make the brake pedal pulsate on application, and in the case of a badly warped rotor the pistons can get knocked back into the caliper body. When that happens more fluid will be required to apply the brakes, which means the brake pedal will have to travel farther.

Another caliper design is the sliding style. These have a single piston on just one side; working like a C-clamp, as the piston pushes the inside brake pad against the rotor. Once it makes contact, the caliper slides in its bracket and pulls the outside pad against the rotor. Ford and Chrysler used this style caliper.

Similar to the sliding caliper is the floating design (typically single-piston GM calipers). Like the sliding caliper, floating calipers apply hydraulic pressure to one pad, then the caliper, which "floats" on a pair of mounting pins, pulls the other pad against the rotor. While the sliding and floating calipers work in a similar fashion, there is one major difference. With the sliding style the braking force is transferred to the caliper, which means it must be a stout piece. With a floating caliper, the mounting bracket captures the pads. As a result, the caliper doesn't have to be as beefy.

Available for '60-62 Chevys (as well as most other GM trucks with IFS) is Wilwood's Superlite 6 Big kit, which includes Billet Superlite six-piston calipers, PolyMatrix brake pads, forged aluminum hubs, machined aluminum hats, and 13- or 14-inch SRP or GT directional-vane rotors. Dropped spindles are also available.

Available for '60-62 Chevys (as well as most other GM trucks with IFS) is Wilwood's Superlite 6 Big kit, which includes Billet Superlite six-piston calipers, PolyMatrix brake pads, forged aluminum hubs, machined aluminum hats, and 13- or 14-inch SRP or GT directional-vane rotors. Dropped spindles are also available.

Types Of Discs

Although disc brake rotors come in a wide variety of sizes, they can be broken down into just two categories: solid and vented. Solid rotors are just that, a simple flat rotor. Simple and inexpensive. The disadvantage to solid rotors is that they do not dissipate heat well. While solid rotors are adequate for lightweight cars, particularly on the rear, a better disc brake rotor option for trucks is the vented style. This design separates the two friction surfaces with air passages to aid in cooling.

Hydraulics

Another important factor in the way brakes function is the amount of pressure available to apply to the friction surfaces against the rotating surfaces. If you've ever stomped on a brake pedal in a panic, you grasp the basic concept; more pressure means a shorter stop. Modern hydraulic brake systems are based on the principles first put forth by a 17th century mathematician, Blaise Pascal. He found that a liquid does not compress and that pressure applied to a liquid in a closed system is transmitted equally to every other part of the system. For our purposes that means if 100 pounds of pressure is applied to a 1-square-inch-piston in the master cylinder that results in 100 psi in the hydraulic system. The fluid passes through the brake lines to a wheel cylinder with a 1-square-inch-piston and it will push with 100 pounds of force.

Now take the same scenario and add three more wheel cylinders and pressure at all the wheel cylinders is the same. Now this is where things get interesting. In this scenario, 100 pounds of pressure is applied to the same master cylinder with a 1-square-inch-piston. The system pressure is still 100 psi; however, now the piston in the wheel cylinder is increased to 3 square-inches. Because the pressure in the system is 100 psi, and the wheel cylinder has 3-square-inches of surface area, the result is the piston pushes with 300 pounds of force. That simply means that increasing the surface area of the pistons at the wheels (disc brake calipers or drum brake wheel cylinders) increases the force applied to the friction surfaces, and all things considered, the more pressure applied to the friction surfaces the more stopping power.

Pedal Ratio

A simple way to mechanically increase the hydraulic pressure in a brake system is to alter the pedal ratio. Pedal ratios are determined by measuring from the pivot point to the master cylinder pushrod and from the pivot point to the pedal pad. Applying 25 pounds of pressure to a 5:1 brake pedal results in 125 pounds of pressure being applied to the master cylinder; with a longer 6:1 pedal ratio, 150 pounds of pressure is applied.

In some cases a larger booster won't fit, so dual-diaphragm boosters are used to supply increased assist. Their stepped housing identifies dual diaphragms.

In some cases a larger booster won't fit, so dual-diaphragm boosters are used to supply increased assist. Their stepped housing identifies dual diaphragms.

Boosters Power brakes are something that most of us expect to find on new trucks and the reason is simple enough. Disc brakes don't self-energize so they require more system pressure than drum brakes to push the pads against the discs to stop effectively. In most cases the simplest method of doing this is to add a brake booster of some sort.

Vacuum Boosters

The most common type of brake booster is the vacuum style. A fairly simple device, they are basically a canister divided into two chambers by a diaphragm. On one side of the diaphragm are the brake pedal and a vent; on the other side is a pushrod to the master cylinder and a hose leading to the intake manifold. When the brake pedal is depressed atmospheric pressure is present on the brake pedal side while manifold vacuum draws the air out of the master cylinder side. The higher pressure on the brake pedal side simply helps apply more mechanical pressure to the master cylinder.

Hydraulic Boosters

This type of booster taps into the power steering line and uses hydraulic pressure to supplement the pedal pressure applied to the master cylinder.

Hydraulic boosters are often found on diesel engines as the vacuum type won't work (diesels don't have manifold vacuum) but they work on gas engines just as well. While hydraulic boosters are ideal for diesels, they also work well on gas engines that have low manifold vacuum as the result of an aggressive camshaft.

In operation, fluid flows from the power steering pump, through the brake booster then on to the steering box. The steering box and the brake booster both have return lines, and to accommodate them the pumps used in these applications normally have two return fittings.

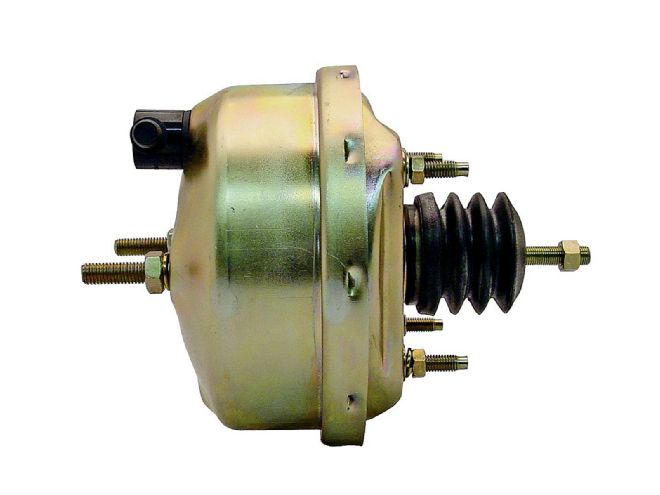

Vacuum brake boosters are another common component of an updated brake system. This is a 7-inch single diaphragm type. Generally, the larger diameter the booster the more assist it will provide.

Vacuum brake boosters are another common component of an updated brake system. This is a 7-inch single diaphragm type. Generally, the larger diameter the booster the more assist it will provide.

When the brakes aren't in use, fluid flows through the booster to the steering box. But when the brake pedal is depressed, pressurized fluid flows through a spool valve into a chamber in the booster. There the fluid applies pressure to a piston, which pushes on the master cylinder providing the power assist.

Also part of the system is a device called an accumulator (some are on the unit, others are remote) that stores enough pressurized fluid for at least one assisted application of the brakes if the engine quits. After that the brakes behave with no assist.

Electric Boosters

Something new on the brake booster scene is the electric type. Used in conjunction with a special master cylinder, hydraulic pressure in the area of 2,500 psi is created by an electric pump. That pressure is then delivered to the master cylinder.

Brake System Valves

Metering

Metering valves, also called hold-off valves are used in the brakesystem to better balance the front to rear brakes. The valve does not allow the pressure to rise at the front disc brakes until the pressure at the rear drums has risen sufficiently to overcome the brake shoe springs. At this point the valve opens to allow full pressure to build at the front brakes.

Proportioning

Proportioning valves modulate the pressure to the rear brakes. They minimize rear wheel lockup found in heavy braking and compensate for differences in braking conditions in front disc/rear drum systems. As pressure is applied to the system full pressure is allowed to the rear drums up to a certain point. Beyond that point the pressure to the rear is reduced preventing rear brake lockup.

Residual

Residual valves maintain a small amount of pressure in drum brake systems to keep the wheel cylinder cups expanded. This prevents air from being drawn into the system and allows the brakes to react quicker. A 10-pound valve is common in drum brake systems.

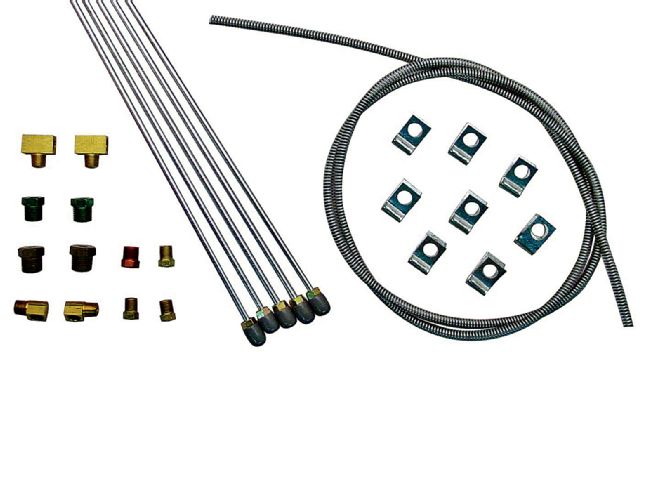

When plumbing hard brake lines there are only two acceptable types of tubing: steel and stainless steel. Flex lines should be DOT-approved rubber hoses or braided lines.

When plumbing hard brake lines there are only two acceptable types of tubing: steel and stainless steel. Flex lines should be DOT-approved rubber hoses or braided lines.

Normally, disc brake systems don't have residual pressure valves, however when the master cylinder is mounted below the floor, and is lower than the calipers, a 2-pound valve is used to prevent the calipers from draining fluid back to the master cylinder.

Combination Valves

A combination valve incorporates metering and proportioning functions into one valve. These are available for disc/drum or drum/drum systems and often have warning light provisions to indicate if one half of a dual brake system has lost pressure.

Adjustable Proportioning Valves

Adjustable proportioning valves are often found on race cars to adjust brake bias as fuel load or track conditions change. On trucks they are often used to "tune" front-to-rear brake balance.

Brake Lines

The first thing that needs to be understood is that the size of the brake lines has no effect on system pressure. With that said, only steel or stainless steel lines should be used and braided line should only be used between the chassis and wheels. Plumbing an entire chassis with braided line can cause a spongy pedal because it will swell slightly in use

When routing brake lines keep them away from heat sources, points of abrasion, and avoid large vertical loops, like over the rear axle, which can cause the system to trap air and make it difficult to bleed.

Brake Buying Tips

First and foremost realize that the major players in the brake business have taken a systems approach to their kits. That means that mixing and matching components from a variety of suppliers may not provide the desired results and you could wind up with a system that is less than the sum of its parts by trying to outguess the manufacturers.

Finally, talk to suppliers about your specific needs and your budget, chances are they've dealt with the same requirements many times before and will have some recommendations.