Once upon a time, more than half a century ago, before Corvettes and stroked small-blocks clouded the waters, the number 427 stood for one—and only one—thing: Ford’s ultimate factory weapon on the NASCAR superspeedway battlefront. An outgrowth of the new-for-1958 FE series big-block V8 engine family, the 427, emerged in 1963 as an extension of the performance-oriented 406 and instantly swept the top five winning spots at the 1963 Daytona 500. Ford really was First On Race Day!

Winning driver Tiny Lund’s 427 Galaxie hammered along at an average of 151.556 mph, cementing the Ford 427 in NASCAR race history forever. But as stout as the 427 was, by 1965, its oiling system proved to be a weak link in all-out race situations. Shared with every other FE big-block—from the base 352 two-barrel up to the triple-carb 390 in Uncle Jimmy’s 1963 T-bird Sports Roadster—the early 427 oiling system routed pressurized oil from the pump and filter to a longitudinally positioned oil galley positioned above the cam tunnel.

From here, oil flow was divided. Half (roughly) went up to the lifters and rocker arms, and half went down to the camshaft journals and main bearing journals. In normal driving situations and most street and strip applications, the system was adequate. But with the arrival of things like Ford’s “7,000 rpm kit,” high-riser heads, and ultra-tall eight-barrel induction systems (which forced the use of “teardrop” hood clearance blisters on the 1964 Fairlane Thunderbolt), above 6,500 sustained rpm, 427 racers began kicking rods and ventilating blocks. More oil flow was needed.

To remedy the situation, in early 1965, Ford revised the 427 oiling system to replace the cam-priority “top-oiler” configuration with a main-priority setup, and the trouble ended. In particular, the 427’s main oil galley was repositioned from above the cam tunnel to the passenger side of the block so pressurized oil was made available to the mains before the top end. The revised 427 has come to be known as the side oiler and, as we’ll see, can easily be identified visually.

In this story, let’s watch as Donnie Wood and the team at R.A.D. Auto Machine revive a dormant 427 side oiler while bringing it into the “stroker age” with a Scat long-arm kit and a set of Edelbrock heads. The resulting 561 hp is probably 100 clicks higher than what Tiny Lund had under foot back in 1963. As for the 676.2 lb-ft of torque, we’d wager that’s almost 200 twisters more than the old days. Best of all, we don’t have to crank it up to 7,000 rpm to get the goods! Revs might be fun, but they generally eat lower end and valvetrain parts—sooner or later.

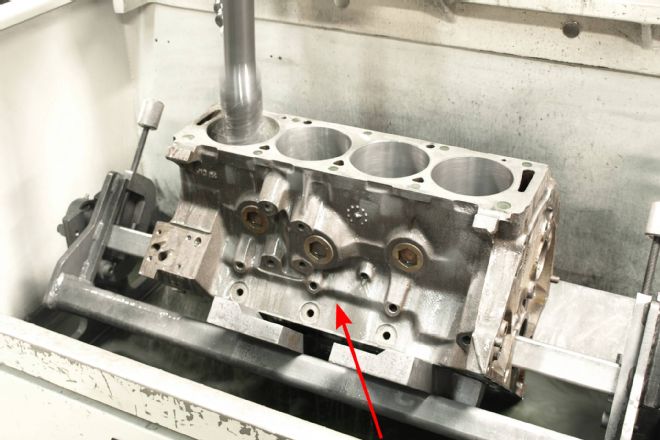

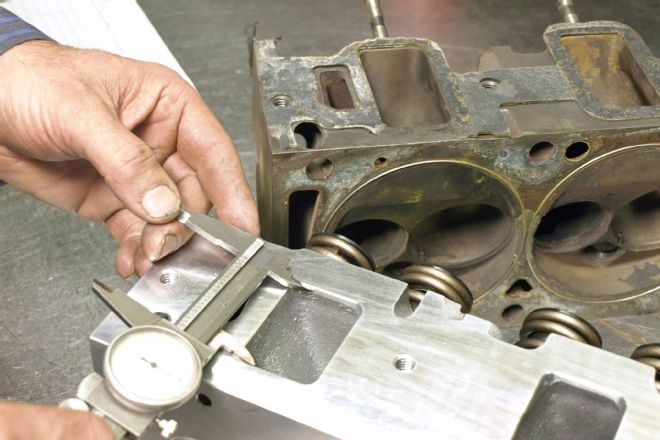

After boring with a torque plate, the Rottler power hone takes the bores from 4.230 to 4.280 inches. The raised horizontal rib above the passenger-side oil-pan rail (see arrow) gives the side-oiler block its name.

After boring with a torque plate, the Rottler power hone takes the bores from 4.230 to 4.280 inches. The raised horizontal rib above the passenger-side oil-pan rail (see arrow) gives the side-oiler block its name.

Never before decked, the R.A.D. Rottler F79A removed 0.008 and 0.014 (passenger side/driver side) to establish the correct and even deck height. Despite numerous cylinder replacement sleeves, the block passed all pressure and crack tests before machine work began. The twin oil galley access holes adjacent to the rear cam tunnel plug (see arrows) indicate this 427 was factory machined with full-length camshaft oil galleys. Only found on industrial, marine, and 1968-model-year blocks, they allow the choice of solid or hydraulic lifters. In this hydraulic-roller-cam-equipped build, they’ll be left as-is. If a solid cam was in the plan, the internal oil galleys would have to be plugged to prevent unwanted/unnecessary oil flow to the solid lifters.

Never before decked, the R.A.D. Rottler F79A removed 0.008 and 0.014 (passenger side/driver side) to establish the correct and even deck height. Despite numerous cylinder replacement sleeves, the block passed all pressure and crack tests before machine work began. The twin oil galley access holes adjacent to the rear cam tunnel plug (see arrows) indicate this 427 was factory machined with full-length camshaft oil galleys. Only found on industrial, marine, and 1968-model-year blocks, they allow the choice of solid or hydraulic lifters. In this hydraulic-roller-cam-equipped build, they’ll be left as-is. If a solid cam was in the plan, the internal oil galleys would have to be plugged to prevent unwanted/unnecessary oil flow to the solid lifters.

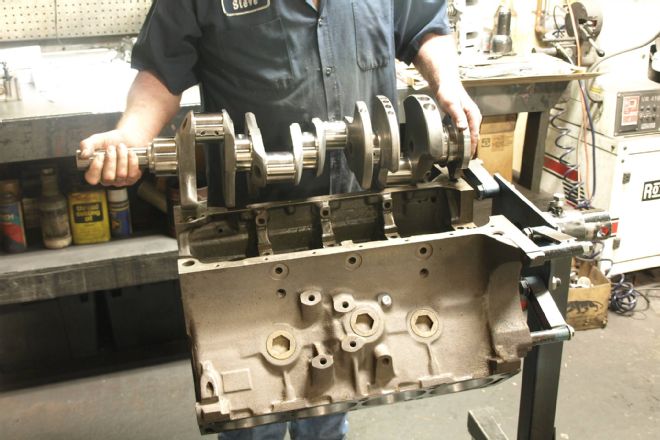

Working with the 0.050 cylinder overbore, the stock 3.78 stroke Ford crank gives way to a 4.250 inch 4340 forged steel replacement from Scat (PN 4FE200) that weighs 63.6 pounds and is internally balanced. Scat also offers a cast-iron version (PN 9FE200, 59.6 pounds) for penny-pinchers. Scat 6.700-inch rods and lightweight J&E forged pistons (521 grams each, PN 242931) complete the rotating assembly.

Working with the 0.050 cylinder overbore, the stock 3.78 stroke Ford crank gives way to a 4.250 inch 4340 forged steel replacement from Scat (PN 4FE200) that weighs 63.6 pounds and is internally balanced. Scat also offers a cast-iron version (PN 9FE200, 59.6 pounds) for penny-pinchers. Scat 6.700-inch rods and lightweight J&E forged pistons (521 grams each, PN 242931) complete the rotating assembly.

To minimize the swing arc of rotating parts inside the crankcase, the Scat H-beam rods (bottom) feature downsized big-end diameters (from 2.43 to 2.20) and compact ARP-sourced rod bolts. The stock rod shown is a C3AE-C 1963–1965 Ford 427 item that uses a two-piece bolt and nut fastener. Only the 427 LeMans rods had cap screws, taking their name from the famed 24-hour French road race where Ford defeated Ferrari for four consecutive years (1966–1969) with a fleet of 427-powered GT40s.

To minimize the swing arc of rotating parts inside the crankcase, the Scat H-beam rods (bottom) feature downsized big-end diameters (from 2.43 to 2.20) and compact ARP-sourced rod bolts. The stock rod shown is a C3AE-C 1963–1965 Ford 427 item that uses a two-piece bolt and nut fastener. Only the 427 LeMans rods had cap screws, taking their name from the famed 24-hour French road race where Ford defeated Ferrari for four consecutive years (1966–1969) with a fleet of 427-powered GT40s.

The compact stroker assembly is so well engineered that zero clearance grinding work is required inside the block. Scat’s forged stroker crank features hollow main journals (the cast version is solid in this location). Both types feature fully radiused, cross-drilled, and chamfered journals. Note the 427-only screw-in core plugs, lesser FE blocks use conventional press-fit cupped plugs.

The compact stroker assembly is so well engineered that zero clearance grinding work is required inside the block. Scat’s forged stroker crank features hollow main journals (the cast version is solid in this location). Both types feature fully radiused, cross-drilled, and chamfered journals. Note the 427-only screw-in core plugs, lesser FE blocks use conventional press-fit cupped plugs.

Designed to prevent the cumulative effect of cap walk from degrading the oil wedge in endurance race applications like the Daytona 500 and 24 Hours of LeMans, the 427’s cross-bolted main caps are not strictly necessary on a street and strip machine. The factory two-bolt caps used on 332-428 FE blocks are sufficient. That said, there’s nothing cooler than spotting the 427’s trio of extra bolts over the oil-pan rail on cruise night!

Designed to prevent the cumulative effect of cap walk from degrading the oil wedge in endurance race applications like the Daytona 500 and 24 Hours of LeMans, the 427’s cross-bolted main caps are not strictly necessary on a street and strip machine. The factory two-bolt caps used on 332-428 FE blocks are sufficient. That said, there’s nothing cooler than spotting the 427’s trio of extra bolts over the oil-pan rail on cruise night!

Unlike the one-piece main caps used on the Chrysler 426 Hemi, Ford’s deep-skirt cross-bolt arrangement employs hardened steel spacers between the caps and block. Specifically machined, then Blanchard ground for a precise fit, you don’t want to mix them up! Fully grooved main bearings from Clevite (PN MS-863P) are used. This view inside the crankcase offers a look at the inner face of the side oiler’s unique oil-galley routing (see arrows).

Unlike the one-piece main caps used on the Chrysler 426 Hemi, Ford’s deep-skirt cross-bolt arrangement employs hardened steel spacers between the caps and block. Specifically machined, then Blanchard ground for a precise fit, you don’t want to mix them up! Fully grooved main bearings from Clevite (PN MS-863P) are used. This view inside the crankcase offers a look at the inner face of the side oiler’s unique oil-galley routing (see arrows).

Fortunately, Ford stamped each spacer (R-1, R-2, R-3 and L-1, L-2, and L-3) to indicate its correct position. The oil-pan rails are also stamped with corresponding numbers (see the 2-L marking in the picture above). It’s foolproof if you’re working with an unmolested engine. The torque-down process is, main caps to 35 lb-ft, side bolts to 45 lb-ft, then main caps to 100 lb-ft. RTV thread sealant must be applied liberally under external washer heads to prevent oil leaks down the side of the block.

Fortunately, Ford stamped each spacer (R-1, R-2, R-3 and L-1, L-2, and L-3) to indicate its correct position. The oil-pan rails are also stamped with corresponding numbers (see the 2-L marking in the picture above). It’s foolproof if you’re working with an unmolested engine. The torque-down process is, main caps to 35 lb-ft, side bolts to 45 lb-ft, then main caps to 100 lb-ft. RTV thread sealant must be applied liberally under external washer heads to prevent oil leaks down the side of the block.

Piston installation must suit the E-I-E-I-I-E-I-E valve-head sequence or contact will result. The J&E forged slugs have inverted domes and 0.250-inch-deep valve-relief pockets to deliver 9.9:1 compression. The 0.990-inch floating pins are retained with double Spiro-Locks, and there is no pin-offset designed into the piston body.

Piston installation must suit the E-I-E-I-I-E-I-E valve-head sequence or contact will result. The J&E forged slugs have inverted domes and 0.250-inch-deep valve-relief pockets to deliver 9.9:1 compression. The 0.990-inch floating pins are retained with double Spiro-Locks, and there is no pin-offset designed into the piston body.

This marine block’s drilled camshaft oil galleys open the door to a hydraulic cam. A Comp Cams Thumper hydraulic roller (PN 33-601-9) was selected to eliminate valve-lash adjustment. Specs are 0.577/0.561 lift, 292/311 advance duration, 235/249 duration at 0.050, 107-degree lobe-separation angle. R.A.D. installed it “straight up” after confirming machining accuracy with a degree wheel. If your 427 block lacks upper oil galleys, sorry, pal—your only choice is a solid cam. But is that really so bad?

This marine block’s drilled camshaft oil galleys open the door to a hydraulic cam. A Comp Cams Thumper hydraulic roller (PN 33-601-9) was selected to eliminate valve-lash adjustment. Specs are 0.577/0.561 lift, 292/311 advance duration, 235/249 duration at 0.050, 107-degree lobe-separation angle. R.A.D. installed it “straight up” after confirming machining accuracy with a degree wheel. If your 427 block lacks upper oil galleys, sorry, pal—your only choice is a solid cam. But is that really so bad?

The Comp Cams Thumper is a single-bolt design, which goes to 75 lb-ft. The timing set is a double row roller from Liberty Performance (PN LT98508T-9) with the all-important one-piece rollers. Never use a timing chain with thin, formed sheet rollers. If you see a seam in each roller, junk it immediately. One-piece, machined rollers are the only way to go.

The Comp Cams Thumper is a single-bolt design, which goes to 75 lb-ft. The timing set is a double row roller from Liberty Performance (PN LT98508T-9) with the all-important one-piece rollers. Never use a timing chain with thin, formed sheet rollers. If you see a seam in each roller, junk it immediately. One-piece, machined rollers are the only way to go.

Oil-pump selection can save power. R.A.D. testing has shown that a high-pressure pump can consume as much as 6 hp while delivering unhealthy 130-psi pressure levels. A standard-grade Melling pump is adequate for this sub-6,000-rpm torquer. Again, despite nearly an extra half inch of stroke, no crankcase grinding was required to clear the Scat stroker kit.

Oil-pump selection can save power. R.A.D. testing has shown that a high-pressure pump can consume as much as 6 hp while delivering unhealthy 130-psi pressure levels. A standard-grade Melling pump is adequate for this sub-6,000-rpm torquer. Again, despite nearly an extra half inch of stroke, no crankcase grinding was required to clear the Scat stroker kit.

The stock 427 oil pan holds 6 quarts and includes an anti-surge baffle to keep the pickup submerged on hard acceleration. Large, full-length windage trays are ideally suited to deep-skirt block configurations like the Ford FE and Chrysler big-block. But they’re controversial in street and strip applications like this. Critics say they’re just as effective at keeping oil from returning to the sump as they are at keeping oil from contacting the spinning crank. To eliminate the hassle of clearancing a tray to suit this stroker, R.A.D. simply left it out in this mild street and strip application.

The stock 427 oil pan holds 6 quarts and includes an anti-surge baffle to keep the pickup submerged on hard acceleration. Large, full-length windage trays are ideally suited to deep-skirt block configurations like the Ford FE and Chrysler big-block. But they’re controversial in street and strip applications like this. Critics say they’re just as effective at keeping oil from returning to the sump as they are at keeping oil from contacting the spinning crank. To eliminate the hassle of clearancing a tray to suit this stroker, R.A.D. simply left it out in this mild street and strip application.

The Comp hydraulic roller lifters are thoroughly immersed in an 80/20 mix of Joe Gibbs assembly lube and 20W50 break-in oil. Besides certain non-automotive units, the only hydraulic cam factory 427 appeared in early 1968 with 390 hp and a single four-barrel. The 428 Cobra Jet replaced it in April 1968.

The Comp hydraulic roller lifters are thoroughly immersed in an 80/20 mix of Joe Gibbs assembly lube and 20W50 break-in oil. Besides certain non-automotive units, the only hydraulic cam factory 427 appeared in early 1968 with 390 hp and a single four-barrel. The 428 Cobra Jet replaced it in April 1968.

ARP ½-inch head studs (PN 155-4201) feature nifty Allen wrench receptacles to aid installation. Head nuts will go to 110 lb-ft. The FelPro head gaskets (PN 8554PT) compress to 0.041 inch and deliver nearly double the 0.028-inch safe minimum clearance between the zero-deck piston crowns and cylinder heads.

ARP ½-inch head studs (PN 155-4201) feature nifty Allen wrench receptacles to aid installation. Head nuts will go to 110 lb-ft. The FelPro head gaskets (PN 8554PT) compress to 0.041 inch and deliver nearly double the 0.028-inch safe minimum clearance between the zero-deck piston crowns and cylinder heads.

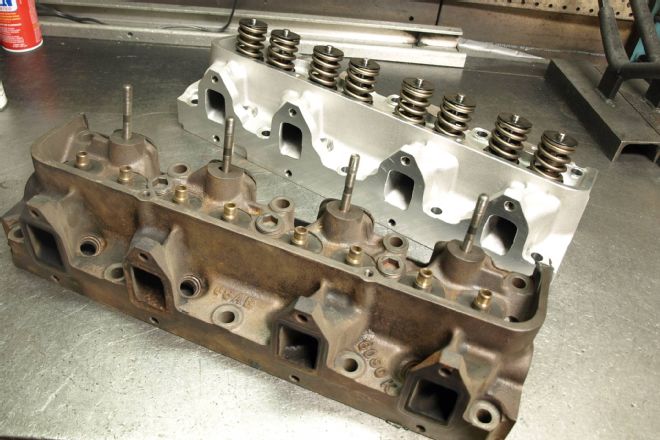

Though the customer wanted to reuse his father’s 1963 C3AE-K cast-iron 427 high-riser heads for sentimental reasons (foreground), the numerous cracks, damaged seats, worn guides, and O-rings posed too many hurdles. They’ll be replaced with a set of Edelbrock Performer 427 low/medium-riser heads (PN 60079) to save 18 pounds (each).

Though the customer wanted to reuse his father’s 1963 C3AE-K cast-iron 427 high-riser heads for sentimental reasons (foreground), the numerous cracks, damaged seats, worn guides, and O-rings posed too many hurdles. They’ll be replaced with a set of Edelbrock Performer 427 low/medium-riser heads (PN 60079) to save 18 pounds (each).

The Edelbrock heads feature 76cc chambers and deliver 9.9:1 compression with the reverse dome pistons. Their 170cc intake port openings measure 2.100x1.375 inches and flow 270 cfm at 0.600 lift and accept all non-high-riser intake manifolds. By contrast, the tall high-riser (background) intake ports are larger at 2.850x1.450 inches, but can only be mated to scarce high-riser intake manifolds.

The Edelbrock heads feature 76cc chambers and deliver 9.9:1 compression with the reverse dome pistons. Their 170cc intake port openings measure 2.100x1.375 inches and flow 270 cfm at 0.600 lift and accept all non-high-riser intake manifolds. By contrast, the tall high-riser (background) intake ports are larger at 2.850x1.450 inches, but can only be mated to scarce high-riser intake manifolds.

R.A.D. retained the Edelbrock 2.09/1.66-inch valves, but performed a little bowl blending beneath the unleaded-fuel-compatible valve-seat inserts. Like all Edelbrock Performer series aluminum Ford cylinder heads, the decks are 5/8-inch thick for rigidity.

R.A.D. retained the Edelbrock 2.09/1.66-inch valves, but performed a little bowl blending beneath the unleaded-fuel-compatible valve-seat inserts. Like all Edelbrock Performer series aluminum Ford cylinder heads, the decks are 5/8-inch thick for rigidity.

Though blasphemous to the if-you-got-it-flaunt-it set, the engine owner asked R.A.D. to remove the engraved Edelbrock logos for stealth points. He also had ’em painted black. Remember, before 1966 when Ford adopted its universal blue-engine policy, most sixes, small-block V8s, and big-block V8s were painted gloss black. The valve covers and air cleaners were then painted various colors (or chromed) to denote power level.

Though blasphemous to the if-you-got-it-flaunt-it set, the engine owner asked R.A.D. to remove the engraved Edelbrock logos for stealth points. He also had ’em painted black. Remember, before 1966 when Ford adopted its universal blue-engine policy, most sixes, small-block V8s, and big-block V8s were painted gloss black. The valve covers and air cleaners were then painted various colors (or chromed) to denote power level.

To suit the hefty hydraulic roller lifters, a set of Comp Cams double valvesprings (with dampers) replace the single-coil Edelbrock items. At 1.840-inch installed height, they deliver 165 pounds on the seat and 430 pounds at 0.557-inch lift. The Edelbrock valves and chrome-moly retainers are reused. The 1.76:1 aluminum roller rockers are from Pro Comp (PN 261-1134) with lifter preload set at 0.040-inch (3/4 turn on each adjuster past zero lash).

To suit the hefty hydraulic roller lifters, a set of Comp Cams double valvesprings (with dampers) replace the single-coil Edelbrock items. At 1.840-inch installed height, they deliver 165 pounds on the seat and 430 pounds at 0.557-inch lift. The Edelbrock valves and chrome-moly retainers are reused. The 1.76:1 aluminum roller rockers are from Pro Comp (PN 261-1134) with lifter preload set at 0.040-inch (3/4 turn on each adjuster past zero lash).

Though dual-quads are slated for installation at a later date, for now a vintage Ford C7AE9425-F 427 single four-barrel intake manifold is used. A Quick Fuel Technology BDQ-850 carburetor with mechanical secondaries meters the fuel. Jetting is 76/84 (primary/secondary). Seasoned FE builders may notice the lack of the lifter valley tray. See the next picture for the reason why.

Though dual-quads are slated for installation at a later date, for now a vintage Ford C7AE9425-F 427 single four-barrel intake manifold is used. A Quick Fuel Technology BDQ-850 carburetor with mechanical secondaries meters the fuel. Jetting is 76/84 (primary/secondary). Seasoned FE builders may notice the lack of the lifter valley tray. See the next picture for the reason why.

R.A.D. received this 427 as a wounded warrior in need of rebuilding. The pen points out scars on the lifter valley tray inflicted by previous efforts to use roller lifters. The tie bars contact the tray, so it must be omitted when solid or hydraulic roller lifters are used.

R.A.D. received this 427 as a wounded warrior in need of rebuilding. The pen points out scars on the lifter valley tray inflicted by previous efforts to use roller lifters. The tie bars contact the tray, so it must be omitted when solid or hydraulic roller lifters are used.

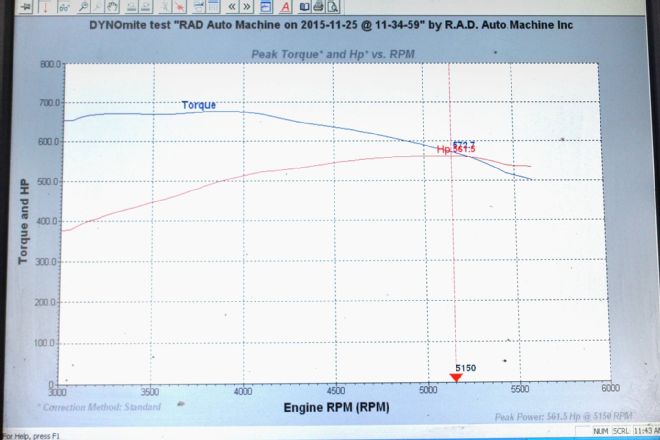

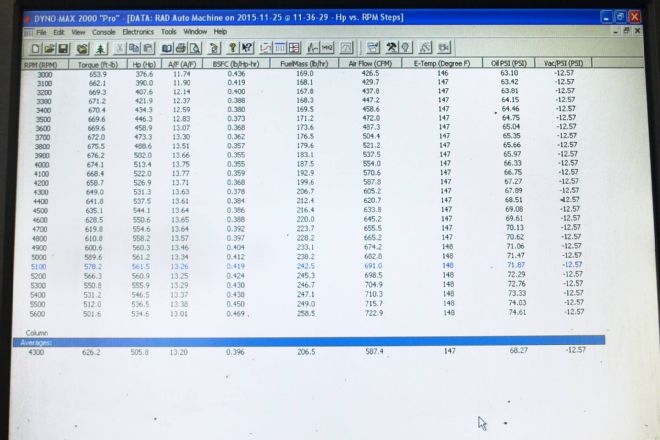

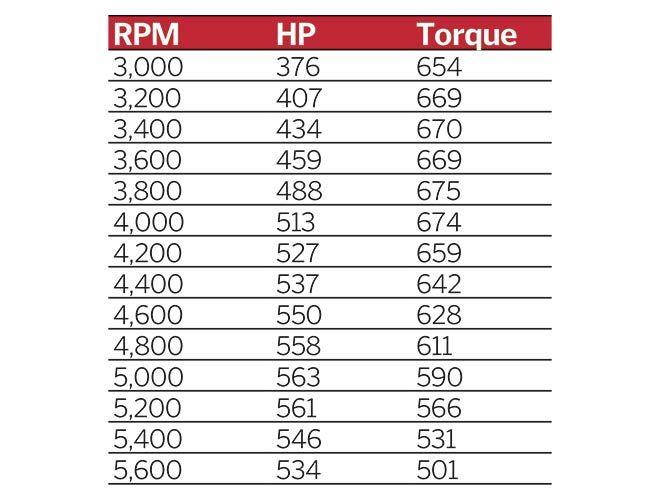

Ready for testing on the Land & Sea Dyno-Max 2000, a pair of FE pickup truck headers (installed upside-down) handle exhaust duty. A Mallory Unilite electronic distributor and Taylor silicone wires handle ignition with advance set at 34 degrees BTDC. With 561.5 peak horsepower coming in at a mere 5,100 rpm and 676.2 lb-ft at 3,900 rpm, the benefits of the 7,000-rpm NASCAR-intended side-oiler block may not be fully utilized, but nobody’s complaining about the 427-only cross-bolted mains.

Ready for testing on the Land & Sea Dyno-Max 2000, a pair of FE pickup truck headers (installed upside-down) handle exhaust duty. A Mallory Unilite electronic distributor and Taylor silicone wires handle ignition with advance set at 34 degrees BTDC. With 561.5 peak horsepower coming in at a mere 5,100 rpm and 676.2 lb-ft at 3,900 rpm, the benefits of the 7,000-rpm NASCAR-intended side-oiler block may not be fully utilized, but nobody’s complaining about the 427-only cross-bolted mains.