For as long as there have been mass production engine rebuilders there has been skepticism about quality and a trail of tears to go with puddles of oil. We’ve all been there one time or another. Need a quick fix to get back on the road Monday? Ready-to-install crate engines enable you to get there. However, when you buy a ready-made remanufactured mill you can drop into your Mustang in a weekend, you expect reliability, which hasn’t always gone hand in hand with remanufactured engines. Horror stories are plenty: missing parts, sloppy tolerances, mismatched pieces, bearing noise, and short service life that doesn’t extend much beyond the warranty. If you experience engine failure under warranty you can be stuck with shipping expense and huge inconvenience.

But what if you could order a new and fiercely reliable high-performance Ford 5.0L Coyote crate engine for about the same money you’d spend on an engine build or ready-to-install reman? During a recent conversation with Mike Delahanty, a marketing manager at Ford Performance, we got into a discussion about crate engines. Delahanty explained why Ford Performance 5.0L Coyote engines from Performance Assembly Solutions are the best bang for the buck performance decision whether you have a 2011-2016 Mustang GT, an F-Series truck, or are considering a classic Fox or SN-95 engine swap.

Time for us to end the crate debate here and now. All Ford Performance Racing Parts crate engines are new and carefully assembled with performance-proven parts manufactured to Ford’s toughest engineering standards. We’ve seen it firsthand and are here to help settle your concerns about crate engines. Delahanty took us out to Performance Assembly Solutions in Livonia, Michigan, for a closer look at how reliable, ready-to-install Ford Performance 5.0L crate Coyotes are built and tested.

Four Steps

Ford 5.0L Ti-VCT Coyote engines arrive at Performance Assembly Solutions hot off the truck from Ford’s Essex, Ontario, Canada, engine plant across the Detroit River outside of Windsor. They arrive crated as box stock factory original engines ready for installation in full dress. These engines are not factory seconds or last year’s leftovers, but in fact a first-rate Essex Engine Plant builds you would find in new 2015-2016 Mustang GTs and F-Series trucks.

What makes these Ford Performance Aluminator engines world class is a strict four-step build and documentation system, according to engineer Mike Robinson of Performance Assembly Solutions (PAS). This is a state-of-the-art quality control process. The first step is a methodical teardown including serialization of key components. Engines arrive, are scanned in, and are disassembled as a package. Parts don’t wind up in gang bins like you see in a lot of reman operations with piles of rods, pistons, cranks, and other parts. All parts are loaded onto a cart and remain together under one common serialized barcode tied to each engine. Each block is hot-washed, rinsed, and dried with compressed air. Cylinder bores are wiped down with light oil to prevent corrosion.

The second step is the blocks, cranks, rods, and pistons are measured and thoroughly inspected the same way they would be by a custom engine builder, one at a time. Think of PAS as a custom engine job shop where engines are processed in small batches to ensure quality. Each position in the measuring and assembly process has a specific responsibility to where every engine is documented to the letter and is a matter of permanent record in a master database. Block, heads, and all components are tied to the same barcode, which means the block, crank, heads, cams, and other components stay together throughout the entire process.

When the measuring and calibration process is complete, the block is mounted on a commercial grade engine stand and enters the third step, the assembly line. The identification barcode is scanned into the system, and every step is monitored and recorded into a database. Instructions and specifications appear on a touchscreen and must be acknowledged as complete by the operator prior to the system allowing him or her to continue the build. In addition to this electronic signoff, the system also records all fastener torque data, the rolling torque data, and even the leak and cold test values.

Bare blocks are fitted with new high-performance main and rod bearings sized to strict specifications. Stock powdered metal connecting rods and pistons are replaced with dynamic-balanced and properly fitted Mahle forged pistons and Manley H-beam rods fitted with ARP 2000 rod bolts. Each crank is dynamic-balanced to the Manley/Mahle reciprocating mass.

What Do I Get for My Money?

5.0L 4V Coyote Ti-VCT 420HP Crate (PN M-6007-M50A)

• High-performance 5.0L four-valve Ti-VCT engine

• 420 hp @ 6,500 rpm

• 390 lb-ft of torque @ 4,250 rpm

• 5.0L (302 ci) displacement

• 3.630-in bore x 3.650-in stroke

• Aluminum block

• Forged steel crankshaft

• Forged steel powdered metal connecting rods

• Hypereutectic pistons

• Aluminum cylinder heads, DOHC, four valves per cylinder, variable intake and exhaust camshaft timing

• 8-qt oil pan

• 11.0:1 Compression ratio

• Tuned composite intake manifold provides efficient air delivery and weight savings

• 80mm single bore “drive by wire” throttle-body

• Mustang GT 409 stainless-steel tubular exhaust manifolds

• Manual transmission engine harness and flywheel included

• Vehicle harness and PCM not included

• Use Ford Racing's new wiring, PCM, and installation kit (M-6017-A504V) designed for street rod/project car installation

• Does not include alternator; for alternator kit see M-8600-M50BALT

• 5.0L Mustang engine cover kit available; see M-9680-M50

• Use Oil Line Adapter M-6881-M50 for applications requiring oil filter relocation

• Engine mount bosses and bellhousing mount pattern common to 4.6L modular engines

• Photo and specs may vary. These features apply for engine code EG-397-AA. Engines are this build code or newer while supplies last.

• Engines built after August 8, 2013, are equipped with a water pump using a three-bolt pulley pattern

• Engine weight: 444 lb

5.0L Coyote Aluminator Naturally Aspirated (PN M-6007-A50NAA)

• Fits 2011-2014 Mustang GT

• 5.0L (302 ci) displacement

• 11.0:1 compression ratio (nominal)

• Mahle hard anodized forged pistons with Grafal low-friction coating

• Manley H-beam connecting rods with ARP 2000 bolts

• BOSS 302 connecting rod bearings

• Forged steel crankshaft

• Uses production Mustang GT aluminum block (M-6010-A50L4V)

• Large rear sump oil pan with 8-qt capacity features optimized oil drainback and windage tray to control oil and improve high-rpm performance

• Tuned composite Mustang GT intake manifold with production “drive by wire” 80mm throttle-body

• Four-valves-per-cylinder aluminum heads with roller-finger followers to reduce friction

• Boss 302 valve springs (M-6513-M50BR)

• Mustang GT production camshafts (Intake: 12mm lift/260 degrees duration, Exhaust: 11mm lift/263 degrees duration)

• Ford Racing engine cover kit (M-9680-M50)

• Manual transmission engine injector harness included

• Front cover is modified for Ford Racing supercharger kits

• For applications not using a Ford Racing supercharger kit, stock timing cover must be installed

• Colder heat range zero (0) spark plugs (M-12405-M50)

• Ford Racing oil filter (M-6731-FL820)

• Billet steel gerotor oil pump (M-6600-50CJ)

• Vehicle harness and PCM not included. Use Ford Racing wiring, PCM, and installation kit M-6017-A504V designed for street rod/project car installation.

• Does not include alternator; for alternator kit see M-8600-M50BALT

• Oil line adapter (M-6881-M50) available for applications requiring oil filter relocation

• Engine mount bosses and bellhousing mount pattern common to 4.6L modular engines

• Engines built after August 8, 2013, are equipped with a water pump using a three-bolt pulley pattern

5.0L Coyote Aluminator SC (PN M-6007-A50SCA)

• Fits 2011-2014 Mustang GT

• 5.0L (302 ci) displacement

• 9.5:1 compression ratio for supercharged applications (nominal)

• Mahle hard anodized forged pistons with Graphal low-friction coating

• Manley H-beam connecting rods with ARP 2000 bolts

• Forged steel crankshaft

• Uses production 2011-2014 Mustang GT aluminum cylinder block

• Large rear sump oil pan with 8-qt capacity features optimized oil drainback and windage tray to control oil and improve high-rpm performance

• Tuned composite Mustang GT intake manifold with production “drive by wire” 80mm throttle-body variable runner control

• Four-valves-per-cylinder aluminum heads with roller-finger followers to reduce friction

• Boss 302 Valve Springs (M-6513-M50BR)

• Mustang GT production camshafts (Intake: 12mm lift/260 degrees duration, Exhaust: 11mm lift/263 degrees duration)

• Ford Racing engine cover kit (M-9680-M50)

• Manual transmission engine injector harness included

• Front cover is modified for Ford Racing supercharger kits

• For applications not using a Ford Racing supercharger kit, stock timing cover must be installed

• Includes colder, heat range zero (0) spark plugs for supercharging (M-12405-M50)

• Includes Ford Racing oil filter (M-6731-FL820)

• Includes billet steel gerotor oil pump (M-6600-50CJ)

• Vehicle harness and PCM not included. Use Ford Racing wiring, PCM, and installation kit M-6017-A504V designed for street rod/project car installation.

• Does not include alternator; for alternator kit see M-8600-M50BALT

• Engine mount bosses and bellhousing mount pattern common to 4.6L modular engines

• Note: Due to 9.5:1 compression ratio, custom tuning is required for optimum performance

5.0L Coyote Aluminator XS (PN M-6007-A50XS)

• Fits: 2011-2014 Mustang GT

• 500-plus hp

• 5.0L (302 ci) displacement

• 11.0:1 compression ratio

• Mahle hard anodized forged pistons with Graphal low-friction coating

• Manley H-beam connecting rods with ARP2000 bolts

• Forged steel crankshaft

• Uses production Mustang GT aluminum cylinder block

• Ford Racing 12-qt rear sump oil pan (M-6675-M50BR) features optimized oil drainback and windage tray to control oil and improve high-rpm performance

• Ford Racing high-performance billet steel oil pump (M-6600-50CJ)

• Ford Racing Cobra Jet tuned intake (preproduction intake manifold shown) (M-9424-M50CJ)

• Ford Racing throttle-body (M-9926-CJ65)

• Four-valves-per-cylinder BOSS fully CNC ported aluminum heads with roller-finger camshaft followers

• Ford Racing Boss valve springs (M-6513-M50BR)

• Ford Racing camshafts [Intake: 13mm lift/263 degrees duration (M-6550-M50BINT), Exhaust: 13mm lift/290 degrees duration (M-6550-M50BEXH)]

• Ford Racing 47-lb fuel injectors (M-9593-LU47)

• Ford Racing high RPM pulse ring (M-12A227-CJ13)

• Ford Racing blue coil covers (M-6P067-M50B)

• Ford Racing heat range zero (0) spark (M-12405-M50)

• Ford Racing oil filter (M-6731-FL820)

• Alternator kit (M-8600-M50BALT)

• Includes production Boss 302 crankshaft damper

• Vehicle harness and PCM not included. Use Ford Racing wiring, PCM, and installation kit M-6017-A504V designed for street rod/project car installation.

• Engine mount bosses and bellhousing mount pattern common to 4.6L modular engines

• Headers not included

• Assembly plant lift brackets not included

• Premium fuel only!

• Note: Custom PCM calibration required when installing M-6007-A50XS crate engine

Although these engines are designed for the 2011-2014 Mustang GT, they’re easily adapted to classic, Fox, and SN-95 applications using the electronics available from Ford Performance Racing Parts.

1. Ford 5.0L Ti-VCT engines enter the Performance Assembly Solutions (PAS) like this: complete factory-assembled engines ready for disassembly and reassembly as beasts from Ford Performance Racing Parts. Each engine is barcoded and strictly documented throughout the process. This engine will emerge exactly as you see here with Manley rods and Mahle forged 9.5:1 or 11.0:1 pistons ready for high-horsepower operation.

2. Each fresh arrival from the Essex Engine Plant is identified, barcoded, and carefully disassembled. All parts are placed on a cart where it all travels together and is reassembled with the same block, crank, heads and other components.

3. Each Coyote block is coded at the Essex Engine Plant and keeps its identity for its entire service life. This particular block was given its identity on April 6, 2015, at 23:39 (11:39 p.m.).

4. This is the PAS barcode, which is used to determine the unique build recipe for the complete engine assembly. This barcode that stays with all engine components as they travel through the PAS build.

5. Here, PAS technician Randall Harris continues disassembly, placing parts on a holding cart.

6. Main caps are carefully removed, serialized, and cleaned, then placed on the traveling cart for use on the same engine they’re removed from.

7. Note the antiseptic and methodical environment in which each engine is maintained as its parts make their way through the assembly process. Block, crank, heads, and all parts are stored and travel together.

8. No guess work here. PAS technician Travis Hopson measures cylinder bores and pistons to ensure a precision fit. Although this is mass production, there’s nothing “mass production” about it. PAS handles dozens of engines at a time, but think of this place as a custom engine build shop.

9. Mahle forged and coated pistons replace the stock slugs because this is about durability and horsepower. These engines are built to withstand well in excess of 500 hp. When we visited PAS the house was full of low-compression Coyotes destined for forced-induction performance.

10. All bearing and journal dimensions are checked and reciprocating mass assembled. These are Manley H-beam connecting rods, which have become a Coyote standard for big horsepower upgrades.

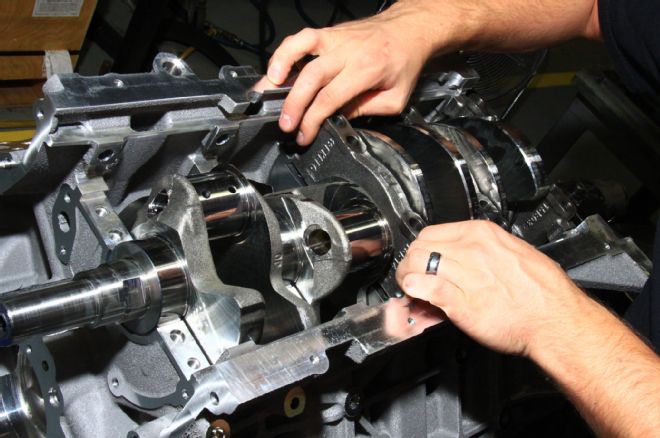

11. Fresh Coyote blocks are fitted with new bearings and the same crankshaft removed to begin with. The forged steel crank has been dynamic balanced to be compatible with Manley rods and Mahle pistons.

12. Once main caps have been set and properly torqued to Ford specifications, endplay is checked and recorded.

13. Mahle pistons have been fitted to Manley H-beam rods and are stuffed into the Coyote’s bores. Cylinders have been coated with oil as well as piston skirts and rings.

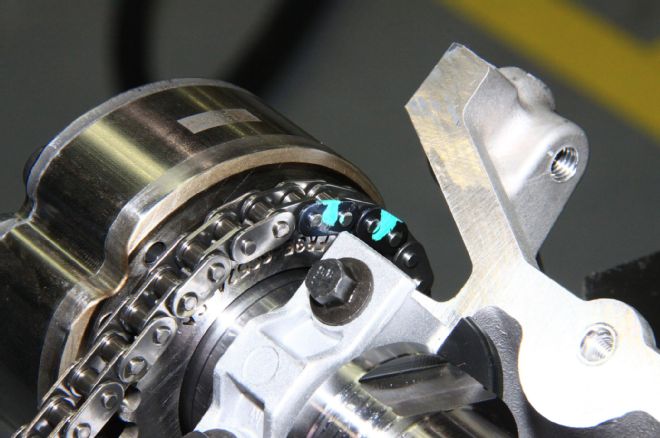

14. ARP 2000 rod bolts are automatically torqued to Ford specifications and marked as torqued with a bright green marker. Because assembly is electronically controlled and monitored, it is virtually impossible to make a mistake. Shawn Staniszewski marks each phase of assembly to ascertain electronic torque has been applied and confirmed at each main cap and connecting rod.

15. A torque-to-turn fixture is mounted to the front of the block and used to ascertain how much torque it takes to turn the rotating assembly. Breakaway torque and average rolling torque are measured. This test is performed on the crank only, and again after the piston and rod assemblies are installed. The test is also conducted on the final engine assembly.

16. Accessories and brackets are installed as the completed short block makes its way down the line. Fasteners are hand-started and run down with a drill, then torqued to final factory specification using sophisticated electronically controlled fastening tools. The computer-controlled system even records the final torque and angle results achieved for every single fastener into the database.

17. This is the 2015 Coyote head, which was removed during teardown. It will go back on the same block it arrived with. Roller followers, lash adjusters, and other components are inspected and reinstalled.

18. When we were at PAS, low-compression Coyotes were being assembled using these dished 9.5:1 forged Mahle pistons engineered for forced induction. These engines are run in batches: sometimes low compression and sometimes high compression.

19. Block decks and heads are wiped down with a tack-free cloth and solvent and fitted with a new set of high-tech, multilayer steel head gaskets.

20. Heads are installed and torqued in sequence using new bolts to Ford specifications.

21. Intake and exhaust cams are lubed and installed as shown. Cam caps are installed and torqued in proper sequence to Ford specifications.

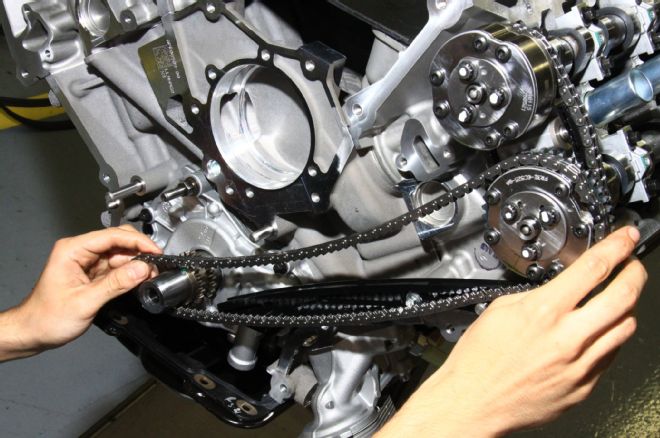

22. Timing chains are installed and properly indexed once cam phasers have been installed and torqued. Timing chain master links are properly lined up on each sprocket and marked in green to confirm the timing.

23. The PAS production line consists of four positions: (1) teardown; (2) measuring and fitment; (3) assembly; and (4) final assembly/testing. Nothing gets past these seasoned technicians because this is not an overwhelming environment. These guys work at a comfortable pace and produce a high-caliber product. That’s Eric Leach putting the finishing touches on this 9.5:1 Coyote.

24. The front timing cover is installed, followed by front dress, the harmonic damper, and water pump.

25. The induction package is next. This is a 2015 intake manifold with charge motion control valves, which makes it different than 2011-2014, which isn’t so equipped.

26. All Ford Performance Racing Parts crate Coyotes are pressure tested for leaks and cold spun to check for oil pressure, compression, and any abnormal sound. Each engine is signed off by the technician who put it together, so there’s accountability in every build. Shawn Staniszewski of PAS signed off on this engine. That’s technician Eric Leach on the cold test stand.

27. Leach finishes up engine dress once cold and pressure testing is done.

28. These are completed 9.5:1 Coyote engines ready for crating and shipping. Ford and Ford Performance don’t hot-test engines anymore like they did back in the day. Manufacturing quality assurance is so good it is unnecessary to fire and run test engines anymore. When you fire up your Ford Performance 5.0L Ti-VCT crate engine in your driveway, it is the first time it will ever have been fired.