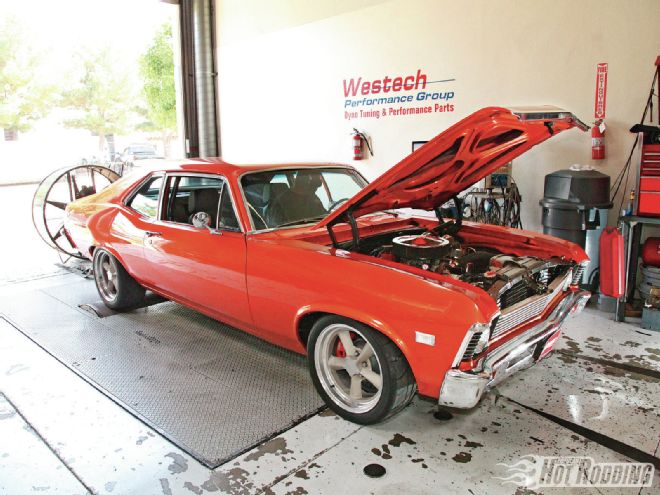

Our ’68 Nova project was nearly finished, but the driveability was poor and the power seemed a bit down. The solution—a half day of tuning on the Westech chassis dyno. The investment was well worth it. Read on to see our tweaks …

Our ’68 Nova project was nearly finished, but the driveability was poor and the power seemed a bit down. The solution—a half day of tuning on the Westech chassis dyno. The investment was well worth it. Read on to see our tweaks …

When we built our Dart 400 SHP small-block and dyno tested it 24 months ago [see “Power in a Package,” Jan. ’10], the idea was to showcase Dart’s line of value-packed short-block crate engines, and combine it with a street-friendly induction combo that would run equally well at the track. At the time, we didn’t know what car the Dart SHP 400 was destined for—the ’68 Nova was still over the horizon. Nevertheless, we knew going in that the Holley 850-cfm Street HP carburetor was a proven performer for street cars in this displacement and power range, so we chose it with the full confidence it would be appropriate for whatever car we acquired. The dyno tuning techniques that apply to Holley’s Street HP are the thrust of our story here, but first, some background.

At the end of our Dart 400 SHP engine buildup, we dyno tested the small-block at Westech Performance Group on their SuperFlow SF902 engine dyno. With a pair of box-stock Dart Pro-1 Platinum cylinder heads, a Dart dual-plane intake, and a COMP Cams Big Mutha Thumpr hydraulic roller cam (243/257 degrees at .050, .533/.519-inch lift, 107-degree LSA), the stout little 10.6:1 compression small-block belted out 523 hp at 5,700 rpm and 523 lb-ft of torque at 4,400 rpm, running through a set of 1¾-inch diameter long-tube dyno headers.

Over the course of building the Nova—or building any project for that matter—things change, and the optimal tune for an engine shifts as the fuel system, exhaust system, cooling, ignition, and load parameters on the engine transition away from the perfect laboratory conditions of the dyno cell. In fact, we noticed pretty much immediately upon swapping the 400 small-block into the Nova that the throttle response became balky, the revs were slow, and the power felt soft. In the short term it didn’t matter; we only needed to move the Nova around the shop while the rest of the build unfolded. Now, however, we were only a few weeks away from hitting the street hard, and we wanted our power back.

All project cars go through a teething stage—the question is, what’s the right way to deal with getting all the power you paid for? The answer is twofold: you need an eddy current dyno with wide-band O2 logging, and you need a tuning expert who can look at the numbers and make the right moves. We had both in the form of Westech’s SuperFlow Autodyn 845 with Windyn data acquisition, and tuning guru Ernie Mena. We also had another significant advantage: the Holley 850-cfm Street HP, which benefits from decades of refinement in carburetor technology. On top of that, we had one of Performance Distributors’ race HEI distributors, which was equipped with their Instant Timing Knob, making quick ignition timing adjustments a snap. Getting our Nova and its Dart SHP 400 back on its game would be cake.

We arrived at Westech’s dyno facility around 8 a.m., and Mena had the Nova strapped to the SuperFlow in no time. After welding on a bung for the SuperFlow’s wide-band O2 sensor, we were up and running. Without making any changes, Mena made a baseline pull. We were pretty relieved to see the air/fuel ratio was way too lean. Why? Because this easily accounted for our lost power and meant the tuning moves would be pretty straightforward. By lunchtime, Mena had tuned us from a peak of 344 hp (at an artificially low peak of 5,000 rpm due to a lean abort) to 385 hp at 5,700 rpm. That’s a peak-to-peak gain of 41 hp, with 6 more horsepower coming in at 5,000 rpm. In the torque department, we improved from 374 lb-ft (4,300 rpm) to 382 lb-ft (at 4,400 rpm)—a peak increase of 8 lb-ft.

That incremental gain might not sound like much, but the process also took our air/fuel ratio out of the danger zone—moving from a piston-frying 14:1 down to a safe 13:1 at WOT. Additionally, Mena made some great moves to vastly improve the cruise, tip-in, and acceleration enrichment of our Holley Street HP. In short, this Nova feels like a totally different animal. Instead of bogging and stumbling at the crack of the throttle, our Dart SHP 400 now smokes the rear tires with ease. More power, more torque, better driveability, and an air/fuel ratio that will keep our engine safe for years to come—what more could we ask for from four hours of well-spent dyno time?

When we built our Dart SHP 400-based small-block, we topped it with a Holley 850-cfm Street HP (PN 0-82851, $540.99 through Summit). It’s the venerable model 4150 brought up to the next level with a cast-aluminum main body without choke horns, and smoothed venturi transitions for increased airflow. It’s aimed directly at optimizing power and includes important modifications like screw-in air bleeds, stainless steel throttle plates, and notched floats. The Street HP also has Dominator-style fuel bowls to allow fuel line plumbing from either side. Easy access to the Street HP’s many tuning parameters allowed for quicker tweaks and more productive tuning sessions.

Our baseline dyno test revealed a very lean 14:1 WOT air/fuel ratio—in fact, it was so lean, the run was aborted at 5,000 rpm. A quick breakdown of the secondary bowl and metering block revealed 92 jets and no power valve. Tuning expert Ernie Mena added a 5.5 power valve—which adds approximately six jet sizes to the secondary fuel circuit once the vacuum transitions below 5.5 inches. The primary power valve was initially a 4.5, but was changed to a 6.5 to hasten the enrichment on the primary side.

Since the throttle tip-in at the beginning of the baseline run was soft to the point of causing a stumble, Mena looked at the primary squirter—which was leaking due to a gasket we had accidentally left out. The squirter was then increased in size from a .031-inch orifice to a larger .042 inch, and the missing gasket was replaced.

The accelerator pump rod was also lengthened to bring in the enrichment sooner and to lengthen the overall stroke for more total enrichment fueling. This kicks in more fuel earlier at the hit and would help remove the lean stumble.

While Holley’s newest carb—the Ultra HP—has clear sight glasses standard, the Street HP still has the old-school plugs. With the car level, the float bowl at operational level, and the engine shut off, unscrew the sight plug and inspect the fuel level. It should be just under the hole. If it’s lower, or spills out when you take the plug out, you’ll need to make a corresponding adjustment to the needle and seat. This rarely needs adjustment from the factory, but should be verified if you’re tuning on the dyno.

Our second dyno pull had more fuel in it and allowed us to go all the way up to 5,900. Power swelled from a peak of 344 hp (at 5,000 rpm) to 375 hp (at 5,800 rpm). The next move would be a change in timing, which was aided by the Instant Timing Knob on our Performance Distributors DUI. Every half turn of the knob equals 1 degree of timing change, so Mena backed off the total timing from 36 degrees to 34 degrees by turning the knob clockwise one full turn.

For run number three, the Dart SHP 400 responded with a big bump—it must’ve liked less timing with this particular jetting combination because power jumped from 375 peak horsepower (5,800 rpm) to 381 peak horsepower (6,000 rpm). The air/fuel ratio, however, was still pretty toasty, peaking at 13.5:1. Mena responded in the fourth dyno run by upping the secondary jets from 92 to 94.

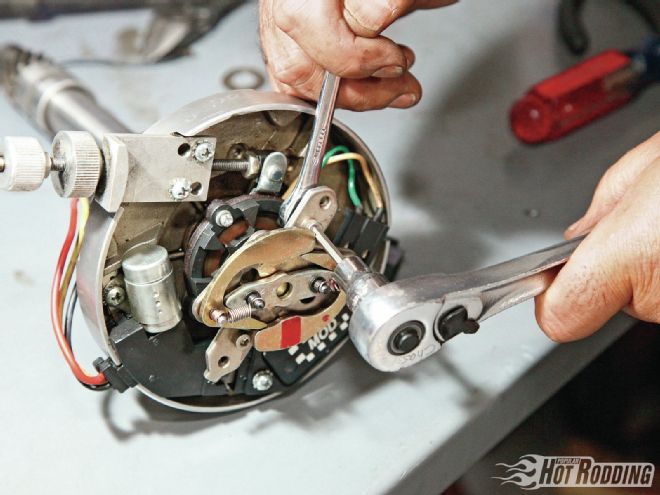

The power responded favorably on run number four, with a new peak of 383 hp coming at 6,000 rpm. Torque was also up—381 lb-ft versus run number three at 379 lb-ft (both at 4,400 rpm). We now decided to focus some effort on the driveability issue, and we found the answer by making a slight change to the timing curve. With a big camshaft like ours, there’s a weak vacuum signal to the jets off idle, resulting in the tip-in stumble. One old hot rodder’s trick around this is to dial in more initial timing. This makes the engine more eager to rev in the absence of fuel enrichment. But advancing the distributor can only do so much, as this necessarily increases the total timing. The answer is to limit the travel on the centrifugal weights, such that you end up with a lot more initial timing, but the same amount of total timing. We called DUI, and they suggested some 10-32 nuts and bolts in the armature to limit the weight travel.

With some steady state dyno tuning, Mena experimented with the amount of initial timing, and got the throttle response on the re-curved DUI razor sharp. Then with two more WOT power pulls and steadily more total timing, he got the peak power even higher, topping out at 385 hp at a much more street-friendly 5,700 rpm. The timing curve now had 28 degrees initial with 37 degrees total.

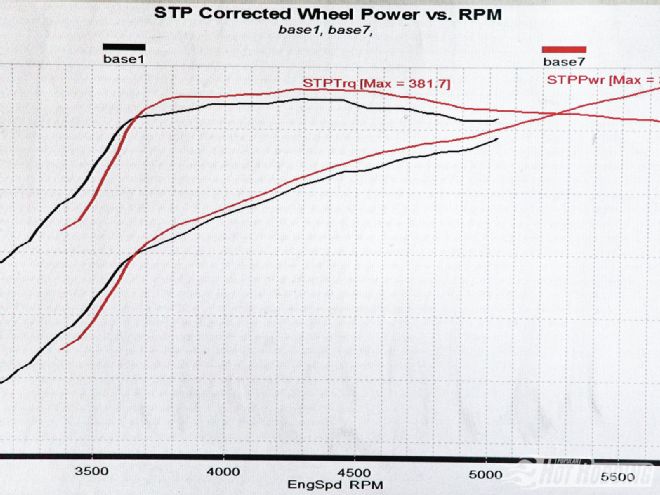

The comparison of our final dyno run (red line) over our baseline test (black line) shows a good return on the time investment with a solid 10 hp and 10 lb-ft average increase throughout—at the drags, this type of improvement is generally worth a tenth on a car like ours. But the biggest difference doesn’t even show up in the graph—it’s in the driving. Since our dyno session, the Nova now responds to throttle input eagerly, which puts a big smile on our faces!

The comparison of our final dyno run (red line) over our baseline test (black line) shows a good return on the time investment with a solid 10 hp and 10 lb-ft average increase throughout—at the drags, this type of improvement is generally worth a tenth on a car like ours. But the biggest difference doesn’t even show up in the graph—it’s in the driving. Since our dyno session, the Nova now responds to throttle input eagerly, which puts a big smile on our faces!

Dyno Cell vs. Chassis Dyno

For those keeping score, we lost 138 hp going from the engine dyno cell to the chassis dyno. This is due to parasitic losses from the Turbo 400 transmission and 12-bolt rear, the addition of a mechanical water pump, the addition of a mechanical flex fan, the addition of an alternator and power steering pump, and the additional—albeit slight—backpressure from a full 3-inch exhaust. This power loss is not really surprising, especially since the chassis dyno is the eddy current variety, which tends to be stingier than an inertial chassis dyno like the Dynojet. On the subject of eddy current versus inertial, it’s important to note that the eddy current dyno can perform valuable steady state tuning—the process of applying a specific load to the driveline without acceleration. The inertia dyno is only effective for tuning at WOT. As a result, the inertial dyno can’t be used as a tool to sort out driveability issues that affect cruise, fuel mileage, part throttle, and tip-in. In our case, driveability tuning was just as important as overall power, and we recommend that if you’re driving your street machine regularly, tuning on an eddy current dyno is the way to go.

As for the Turbo 400 three-speed automatic, these are notoriously power hungry, and impose a heavy toll when comparing the same engine on a chassis dyno. Nevertheless, the loss is offset by the Turbo 400’s excellent strength, low cost, and simplicity. When we get the Nova on the quarter-mile, we fully expect it to go deep 11s, even though the chassis dyno needle only swings to 385 hp.

Catch the Video!

You can see the entire dyno tuning process at Westech by logging on to the PHR YouTube channel at www.YouTube.com/PopularHot Rodding. Look for the video titled “1968 Nova—Dyno Tuning For Power.”