The LSX376-B15 crate engine has proven itself to be not only a capable performer but an LS platform literally begging for boost. Advertised by Chevrolet Performance to accept “up to 15 psi of boost” (thus the 15 in B15), we can say with absolute certainty that their suggested boost limitations were wildly conservative. In our last adventure with the B15, we pumped up the pressure to nearly 29 psi, effectively doubling the limit suggested by GM. The boosted B15 more than just survived, it thrived. After running multiple cam profiles with a 4.0L Whipple supercharger, we eventually cranked up the boost and made nearly 1,000 hp before belt slippage stepped in to ruin the pressure party. Though there was more power to be had with the twin-screw setup, we switch gears by swapping out the Whipple for a brand-new boost builder. Enter the turbocharged B15!

In truth, the B15 couldn’t care less where the boost came from, but there were decided differences between the boost offered by a supercharger and a turbocharger. The major difference between the two methods of forced induction was the energy used to develop said boost. On a typical twin-screw supercharger, the rotors are driven directly off the crankshaft. Much like other accessories (AC, power steering, or alternator), there are parasitic losses associated with driving the supercharger. The higher the power and boost level, the greater the power losses associated with driving the supercharger. That power is actually produced by the engine, but, unfortunately, absorbed by the blower. The end result is that the power is neither registered on the dyno nor available to accelerate your vehicle. By contrast, the turbo is driven off exhaust energy and, unless backpressure is excessively high, the losses associated with driving the impeller are minimal. A turbo will usually produce more power per pound of boost than a typical supercharger, with that differential increasing with pressure and output.

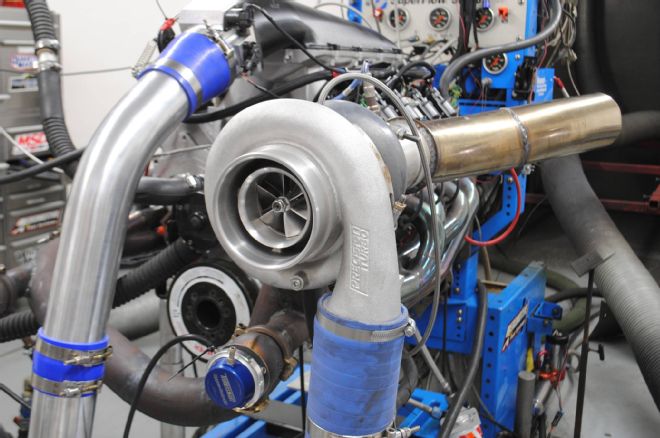

Excited that the turbo offered more power potential on paper, we were anxious to apply that theoretical power to the B15 crate motor. To prepare for turbo boost, we replaced the Whipple supercharger and dedicated blower cam with a Holley Hi-Ram intake and Stage 3 turbo cam from Brian Tooley Racing. The single-turbo system consisted of a pair of turbo manifolds (tubular headers) from DNA Motoring combined with a custom Y-pipe designed to accept a T4 flange. Looking for nothing less than four-digit power levels, we selected a 76mm Precision turbocharger. The PT7675 featured a 76mm compressor wheel, GT42-style compressor housing with a V-band discharge flange, and a 75mm (84 trim) turbine wheel. We started out with the 1.12 A/R exhaust housing, but ultimately switched to the larger 1.28 housing. Boost from the Precision turbo was fed through an air-to-water intercooler from CX Racing and controlled by a pair of Turbo Smart wastegates using their manual controller. The final touches included larger injectors controlled by a Holley Dominator EFI system.

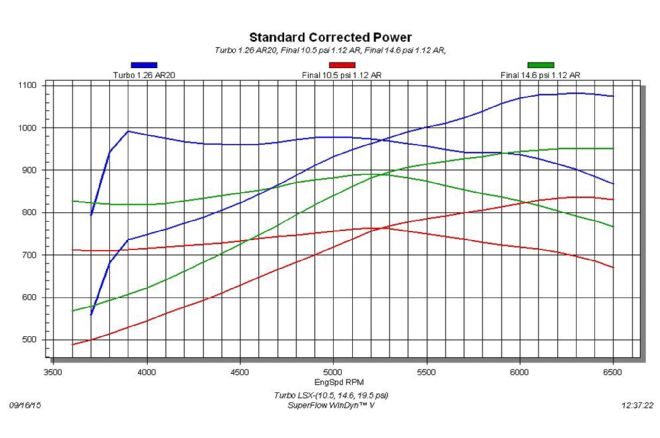

It was obvious right off the bat that the B was begging for boost, as the turbocharged LSX immediately belted out impressive power numbers. Running just 10.5 psi at the power peak, the turbocharged LS produced 836 hp and 760 lb-ft of torque. In a perfect world, the wastegates would maintain a flat boost curve once the motor came up on boost, but our system produced a falling boost curve. The culprit was likely excessive backpressure in the single-turbo system, because the wastegate functions when boost overrides the supplied wastegate spring pressure. Unfortunately, the backpressure applied to the wastegate valve combines with the boost supplied to the diaphragm to prematurely open the wastegate and excessive (or ever-increasing) backpressure makes life difficult for proper boost control. Regardless, the turbo B15 still produced amazing power, with 951 hp coming at 14.6 psi then 1,082 hp at 19.5 psi. After eclipsing the 1,000hp mark, you’d think we would be satisfied, but we had a B15 just begging for more boost. Since the amazing little crate motor shrugged off all the abuse from our single turbo, maybe next time we need to hit this thing with multiple power-adders.

When we last left this LSX crate motor, it was sporting a Whipple supercharger and a new blower cam from Brian Tooley Racing. After cranking up the boost, we eventually made just less than 1,000 hp but ran into some belt-slippage problems after exceeding 28 psi.

When we last left this LSX crate motor, it was sporting a Whipple supercharger and a new blower cam from Brian Tooley Racing. After cranking up the boost, we eventually made just less than 1,000 hp but ran into some belt-slippage problems after exceeding 28 psi.

To illustrate that the B15 was ready for boost from any source, we replaced the Whipple supercharger with a single 76mm Precision turbo.

To illustrate that the B15 was ready for boost from any source, we replaced the Whipple supercharger with a single 76mm Precision turbo.

The Whipple supercharger and lower manifold were replaced by a Holley Hi-Ram intake manifold and FAST 102mm throttle-body. We also upgraded the 83-pound Holley injectors with a set of 120-pounders.

The Whipple supercharger and lower manifold were replaced by a Holley Hi-Ram intake manifold and FAST 102mm throttle-body. We also upgraded the 83-pound Holley injectors with a set of 120-pounders.

Loyal readers will recall that we previously upgraded the factory valvesprings with this dual-spring setup from Brian Tooley Racing. The spring upgrade allowed us to run the dedicated blower cam with the Whipple supercharger.

Loyal readers will recall that we previously upgraded the factory valvesprings with this dual-spring setup from Brian Tooley Racing. The spring upgrade allowed us to run the dedicated blower cam with the Whipple supercharger.

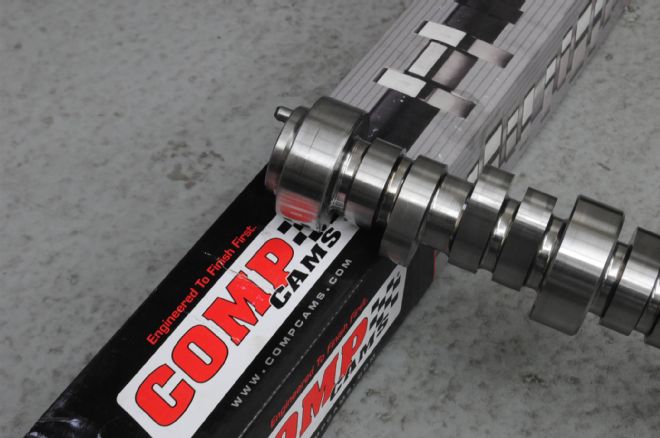

The spring upgrade also allowed us to safely replace the blower cam (run with the Whipple) with a BTR Stage 3 turbo cam. Ground by Comp Cams, the dedicated turbo grind offers .0.609/0.610-inch lift, 230/235-degree duration, and a more turbo-friendly 114-degree lobe-separation angle.

The spring upgrade also allowed us to safely replace the blower cam (run with the Whipple) with a BTR Stage 3 turbo cam. Ground by Comp Cams, the dedicated turbo grind offers .0.609/0.610-inch lift, 230/235-degree duration, and a more turbo-friendly 114-degree lobe-separation angle.

For turbo use, we installed this Moroso oil pan (pick up and windage tray). Note the bulkhead oil return fitting used with the turbo.

For turbo use, we installed this Moroso oil pan (pick up and windage tray). Note the bulkhead oil return fitting used with the turbo.

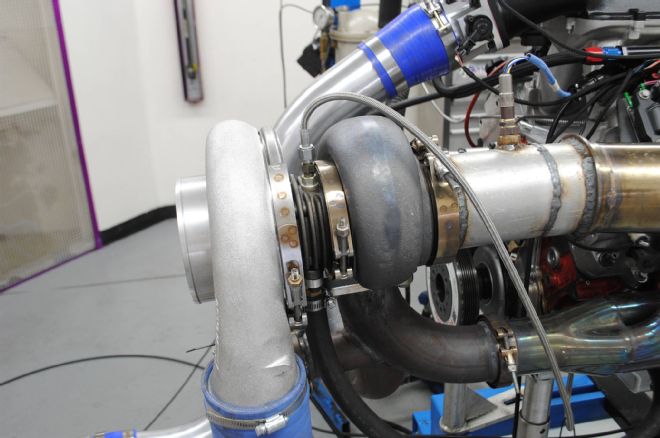

The Precision turbo required both a high-pressure oil feed and low-pressure return back to the pan. The use of V-band clamps facilitated proper orientation of the compressor and turbine housings.

The Precision turbo required both a high-pressure oil feed and low-pressure return back to the pan. The use of V-band clamps facilitated proper orientation of the compressor and turbine housings.

Feeding the turbo was a set of tubular turbo manifolds provided by DNA Motoring. The manifolds featured stainless steel construction and V-band flanges to connect to our custom Y-pipe.

Feeding the turbo was a set of tubular turbo manifolds provided by DNA Motoring. The manifolds featured stainless steel construction and V-band flanges to connect to our custom Y-pipe.

Completing the hot side of the turbo system was a custom Y-pipe that featured V-band connections for the turbo manifolds, a T4 turbo flange, and a pair of wastegate flanges designed to accept the dual 45mm Hypergate wastegates from Turbo Smart. The hot gases exited the turbine housing through a 4.5-inch exhaust equipped with the necessary oxygen-sensor bung for monitoring the air/fuel ratio.

Completing the hot side of the turbo system was a custom Y-pipe that featured V-band connections for the turbo manifolds, a T4 turbo flange, and a pair of wastegate flanges designed to accept the dual 45mm Hypergate wastegates from Turbo Smart. The hot gases exited the turbine housing through a 4.5-inch exhaust equipped with the necessary oxygen-sensor bung for monitoring the air/fuel ratio.

Like the Whipple supercharger, the turbo system featured an air-to-water intercooler. This core from CXRacing maximized airflow with 3.5-inch inlet and outlets. We relied on dyno water for cooling, though additional power was available with ice water as the cooling medium. This intercooler dropped the air-intake temps by more than 140 degrees. The cold side of the turbo system included 3.5-inch aluminum tubing and couplers used to connect the turbo to the intercooler and the intercooler to the throttle-body.

Like the Whipple supercharger, the turbo system featured an air-to-water intercooler. This core from CXRacing maximized airflow with 3.5-inch inlet and outlets. We relied on dyno water for cooling, though additional power was available with ice water as the cooling medium. This intercooler dropped the air-intake temps by more than 140 degrees. The cold side of the turbo system included 3.5-inch aluminum tubing and couplers used to connect the turbo to the intercooler and the intercooler to the throttle-body.

To eliminate compressor surge under high-boost, lift-throttle conditions, we installed a Turbo Smart Race Port blow-off valve.

To eliminate compressor surge under high-boost, lift-throttle conditions, we installed a Turbo Smart Race Port blow-off valve.

Tuning was critical on a high-horsepower, turbo LS application, so we relied on this Holley Dominator EFI system to dial in the air/fuel and timing curves.

Tuning was critical on a high-horsepower, turbo LS application, so we relied on this Holley Dominator EFI system to dial in the air/fuel and timing curves.

Concerned about backpressure, we even tried stepping up the A/R of the turbine housing from 1.12 to 1.28 to reduce backpressure and improve exhaust flow. The change netted a 1-psi increase in boost and a 1.25-psi decrease in backpressure. Once we had everything dialed in, we raised the boost using a manual wastegate controller. Running 10.5 psi, the turbo LSX produced 836 hp, which jumped to 951 hp at 14.6 psi. The final run netted 1,083 hp at 19.5 psi, illustrating that regardless of the source, the little B15 crate motor was always begging for boost.

Concerned about backpressure, we even tried stepping up the A/R of the turbine housing from 1.12 to 1.28 to reduce backpressure and improve exhaust flow. The change netted a 1-psi increase in boost and a 1.25-psi decrease in backpressure. Once we had everything dialed in, we raised the boost using a manual wastegate controller. Running 10.5 psi, the turbo LSX produced 836 hp, which jumped to 951 hp at 14.6 psi. The final run netted 1,083 hp at 19.5 psi, illustrating that regardless of the source, the little B15 crate motor was always begging for boost.

Single Turbo LSX-10.5 vs. 14.6 vs. 19.5 psi

Raising the boost pressure supplied by the turbo had a positive effect on power. Equipped with the Brian Tooley Racing Stage 3 turbo cam and Holley Hi Ram intake, the turbocharged LSX produced 836 hp and 760 lb-ft of torque at 10.5 psi. Stepping up the boost to 14.6 psi resulted in a jump to 951 hp and 891 lb-ft. The final run netted 1,083 hp and 992 lb-ft of torque at a boost pressure of 19.5 (see boost curves). With a consistent boost curve, the peak power number would be even greater, but we were within 100 hp of the flow limit of the single turbo, so what this LSX motor really needed to make more power was a twin-turbo setup.

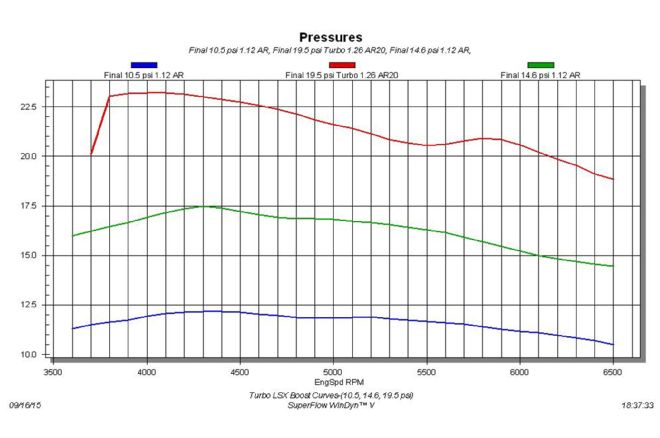

Single Turbo LSX Boost Curves-10.5 vs. 14.6 vs. 19.5 psi

As evident by the graph, the single-turbo system produced a falling boost curve. The 836hp, 10.5-psi run (bottom) actually started out with 11.3 psi, then rose slightly to 12.2 psi before dropping off to a low of 10.5 psi at the power peak. The subsequent runs at higher boost produced similar curves. The 951hp, 14.5-psi run (middle) started out at 16.0 psi, rose to 17.5 psi, then fell off rapidly to just 14.5 psi. The final 1,082hp (top) run continued the trend, starting at 23.2 psi before dropping down to 18.8 psi. Data logging showed the backpressure to exceed boost pressure by more than 10 psi (and climbing) at the power peak.