Funny how it’s usually the little dudes that insist that size doesn’t matter. Let’s call them the insecure midgets sitting in the corner. It’s an interesting, perhaps delusional theory, but where would LeBron James and Ron Jeremy be without their impressive, um, physical attributes? Fortunately for little dudes, there’s this thing called money. And fortunately for the small-displacement engines of the world, there’s this thing called rpm. Just like a big stack of Benjamins adds several inches of perceived height in the eyes of the ladies, tach-straining rpm adds a big chunk of perceived cubic inches to any engine. Case in point: Mast Motorsports’ 388ci LS screamer. Despite measuring just 12 cubic inches larger than a stock LS3 small-block, thanks to its ability to turn 8,000 rpm, it cranks out 725 horsepower. Yes, size matters, but so does rpm.

Sit back and chew on these numbers for a moment. Back in 1957, hot rodders wet their pants when the 283ci fuelie small-block Chevy hit the magical 1 hp per cubic inch mark. Now in 2015, this Mast 388 kicks out an astounding 1.86 hp per cube. That’s within striking distance of the 1.91 hp per ci produced by the Ferrari F12, which just happens to pack the most powerful V-12 ever built by the Scuderia. Of course, horsepower per liter has always been the ricer’s metric of choice. In that category, the 114.1 hp per liter churned out by the Mast 388 tops the Lamborghini Aventador (106.3), Audi R8 V-10 (105.8), and the Porsche 911 GTS (113.2). That’s not too shabby at all for a primitive two-valve, pushrod engine going up against exotics pimpin’ four and five valves per cylinder.

Small Cubes, Big Power

Elementary mathematics clearly illustrates why displacement and rpm are equally important. Since calculating horsepower involves multiplying torque by rpm, then dividing that product by a constant (5252), the only way to increase horsepower is by increasing torque or rpm. Simple enough. Larger engines have the distinct advantage of producing more torque than a smaller engine, even if both are equipped with identical cylinder heads and camshafts. If two hypothetical engines—a big one and a small one—turn the same maximum rpm, yet the larger engine produces more torque, then the larger engine will produce more horsepower. This is precisely why all race organizers on earth enforce rules that limit maximum displacement or provide weight breaks for cars opting for smaller engines.

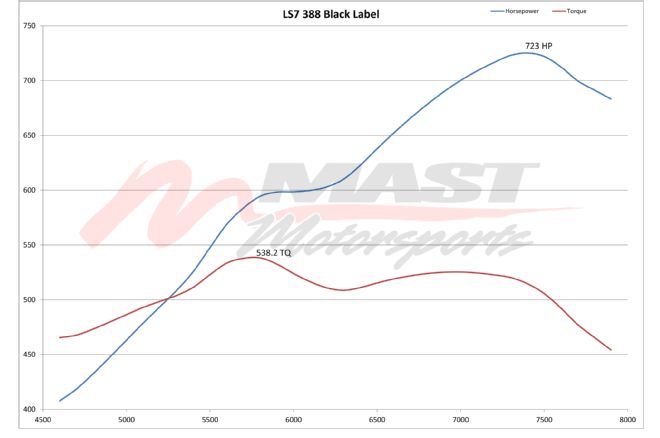

On the flip side, a smaller-displacement engine can make up for its lower torque output by multiplying that torque by more rpm. This explains how the previous generation of 18,000-rpm Formula One V-8s achieved similar hp output (750-800) as the current generation of 9,000-rpm NASCAR Sprint Cup V-8s despite having less than half the displacement (2.4L vs. 5.8L). That’s obviously a rather extreme example, but a quick glance inside Mast Motorsports’ crate engine catalog reveals a more suitable comparison. The company’s LS7 427 SS offering measures 39 cubic inches larger than the 388, but comes equipped with the same Black Label 285cc cylinder heads. Not surprisingly, the 427 produces 573 lb-ft of torque to the 538 lb-ft produced by the 388. As a result, the 388’s smaller displacement requires turning an additional 900 rpm (7,400 vs 6,500) before reaching peak power.

Here’s where things get interesting. The Mast 388 actually produces a substantial 75 horsepower more than the company’s bigger 427ci small-block. To take advantage of the deep-breathing potential of Mast’s Black Label LS7 cylinder heads, the 388 benefits from a larger 264/274-at-0.050 solid roller camshaft compared to the 427 SS’s 246/260-at-0.050 hydraulic roller. The 388 also boasts more valve lift—0.776/0.756-inch versus 0.659/0.666—to further increase airflow into the cylinders. The 388 also utilizes a tall single-plane intake instead of the conventional composite intake found on the Mast 427 SS. The combination of a larger intake, longer camshaft duration, higher valve lift, and the faster valve opening rate inherent to the solid-lifter cam lobe design extends the rpm range of the powerband while also increasing torque output.

Although the smaller engine in this scenario does in fact make more power than its larger counterpart, concluding that a small-displacement, high-rpm combo is inherently superior based on this example alone is absolute nonsense. In this case, the 388 tops the 427 in the hp department due primarily to its larger camshaft and freer-flowing intake manifold. With the same intake, camshaft and matching valvetrain hardware, the 427 would produce more torque and similar horsepower numbers as the 388, but at lower rpm. In theory, since the 427 measures roughly 10 percent larger than the 388, it could turn 10 percent fewer rpm (6,660) and still achieve similar peak horsepower, thus decreasing stress on the valvetrain and rotating assembly.

Road Course DNA

Obviously, Mast’s standard 427 SS crate engine and its custom solid-lifter 388 prove that there are two ways to skin a cat. Nevertheless, even if a smaller engine can make just as much power as a larger engine, what’s the point of turning more rpm if it increases stress on engine internals and sacrifices torque? The answer is one part pragmatism and two parts hooliganism.

This particular custom Mast 388ci combination is destined for a Pro Touring C3 Corvette built by Detroit Speed and Engineering. Although Kyle Tucker and the crew at DSE have plopped countless 427- and 454ci Mast Gen IV small-blocks into Camaros and Chevelles, they felt that a small-displacement, high-rpm combination better suited the lightweight C3’s persona. “Kyle approached us at PRI 2014 about building a custom engine package that was a bit different from the norm. He wanted a high-rpm motor that made 700 hp at around 7,500 rpm,” Joel Iles of Mast Motorsports recalls. “He wasn’t too concerned about hood clearance, so that gave us the flexibility to go with a single-plane intake manifold and a 4500-style throttle body. Kyle wanted the motor finished in a quick timeframe. When we stopped by the Callies booth, they said they had a 3.625-inch crank in stock, so the project came together from there.”

Thanks to legendary big-blocks like the 454 LS6 and 427 ZL1, hot rodders are hardwired to lust after big cubic inches. While massive torque output may suit the needs of a two-ton street/strip Chevelle just fine, the road-course-bound DSE C3 has different priorities. Destined to compete in Ultimate Street Car Association events, which involve delicately modulating the throttle on the autocross and road course, epic heaps of low- and mid-range torque can make it difficult to apply the power on corner exit. Since the Mast 427 measures 10 percent larger than the 388, if equipped with the same solid-lifter cam as its smaller counterpart, it would produce roughly 10 percent more torque (597 lb-ft). That’s not necessarily a good thing when cornering grip is at a premium. Furthermore, extending the powerband by an additional 1,000 rpm can potentially eliminate time-wasting shifts. While a more manageable torque curve and an extended rpm range offer practical advantages, the visceral thrill of winding the tach out and listening to the engine scream at 8,000 rpm is pure hooliganism at its finest.

Over-Square Advantage

In any form of racing where sanctioning bodies ban power-adders and impose cubic inch limitations, over-square cylinder dimensions reign supreme. In these classes, engine builders will typically make the bore diameter as large as the block’s bore spacing and cylinder wall thickness will allow, then set the stroke at whatever length is necessary to meet the cubic inch limit. For example, 500ci NHRA Pro Stock engines utilize a massive 4.750-inch bore and a very short 3.520-inch stroke. In addition to decreasing piston speed—and therefore friction—compared to an under-square engine of the same displacement, the big-bore, short-stroke architecture creates more room inside the cylinders for larger valves. Furthermore, increasing the distance between the cylinder wall and valves helps de-shroud the valves for enhanced airflow.

But wait, there’s more. “In addition to reducing piston speed and friction, a short-stroke crank has less windage because the counterweights are smaller and the outside edge of the counterweights are closer to the crankshaft centerline. This also reduces rotating mass,” Mast’s Joel Iles explains. “Using longer 6.350-inch connecting rods also allows a reduced compression height of the pistons, which reduces reciprocating mass. The result is a faster-revving engine. The torque curve of this engine is insane. It doesn’t peak until about 5,700 rpm, but it stays flat all the way to 7,600 rpm.”

Since there is no cubic inch limit in the classes DSE will be racing its Corvette in, Mast was free to decrease stroke length (and therefore displacement) to whatever provides the best compromise between mid-range torque and high-rpm horsepower. With a torque curve that hits hard after 5,000 rpm, and a power curve that keeps on chugging past 8,000 rpm, Joel Iles and the Mast Motorsports crew have successfully built a race engine that will help the DSE Corvette put the power down out of corners and haul ass down the straights.

Mast 388ci LS7 RPM TQ HP 4,600 465 408 4,700 419 418 4,800 473 432 4,900 480 448 5,000 486 463 5,100 493 478 5,200 499 494 5,300 504 509 5,400 511 525 5,500 523 548 5,600 533 569 5,700 538 584 5,800 538 594 5,900 533 598 6,000 524 599 6,100 516 600 6,200 511 603 6,300 509 610 6,400 511 623 6,500 515 638 6,600 519 652 6,700 522 665 6,800 524 678 6,900 525 690 7,000 525 700 7,100 524 709 7,200 523 717 7,300 520 723 7,400 515 725 7,500 506 722 7,600 492 713 7,700 477 700 7,800 466 691 7,900 454 683

01. The Mast 388ci Gen IV screamer is essentially a de-stroked version of the company’s popular 427ci LS7 crate engine. The major differences are a big solid roller camshaft, a single-plane intake manifold, and an extra 1,000 rpm.

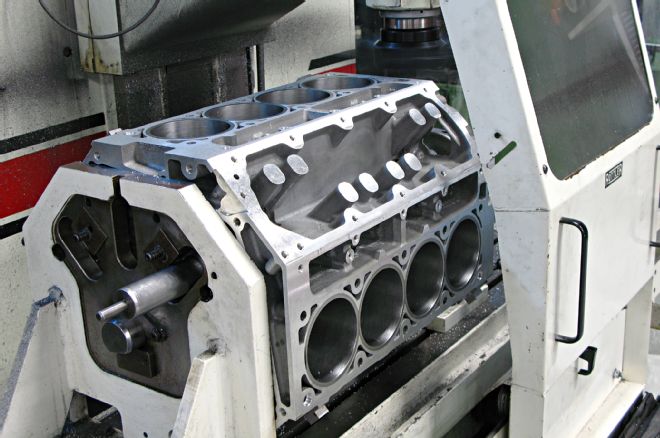

02. The factory GM LS7 block has been decked to 9.230 inches and finish-honed to a final bore diameter of 4.130 inches. After align-honing the stock main caps, the block was ready for assembly.

03. The 388’s shorter stroke allows for the use of 6.350-inch Callies Ultra I-beam connecting rods that are slightly longer than the 6.125-inch units found in Mast’s standard 427 SS crate package. This yields a higher 1.75:1 rod-to-stroke ratio versus the 427’s 1.53:1 ratio, resulting in reduced side loading on the cylinder walls.

04. Although the benefits of a higher rod-to-stroke ratio is a topic of profuse debate, longer rods do in fact push the wristpins closer to the piston crown. This reduction in compression height nets a decrease in piston weight. With a 1.080-inch compression height, the custom Diamond pistons check in at 473 grams each.

05. One of the downsides of decreasing the piston-swept volume of a cylinder is that it also decreases the compression ratio. To compensate, the Diamond pistons feature a 7.2cc dome.

06. Sealing in the cylinder pressure are standard-tension Total Seal AP 0.043-inch top rings, 1.5mm Napier second rings, and 3mm oil rings. The top and second rings have been gapped to 0.020- and 0.018-inch, respectively.

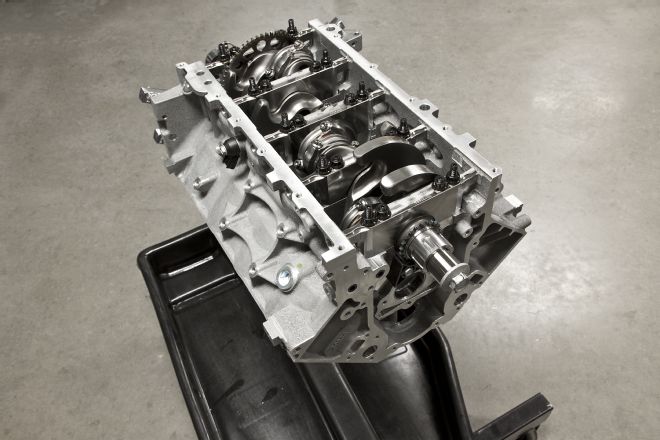

07. The premium-grade Callies Magnum 3.625-inch crankshaft is forged from 4340 steel and boasts gun-drilled mains and profiled counterweights to reduce mass. They’re affixed to the block with factory LS7 billet main caps. With a shorter stroke than a stock LS7, clearancing isn’t required.

08. To achieve the desired compression, Mast set the piston deck clearance to “0.012-inch out of the hole.” When combined with 69cc combustion chambers and 0.051-inch Cometic MLS head gaskets, the compression ratio checks in a 12.0:1.

09. Actuating the valves is a custom Cam Motion 264/274 at 0.050 solid roller camshaft with 0.776/0.756-inch valve lift. Its additional 18 degrees of intake duration and extra 0.117 inch of lift over Mast’s standard 427 SS cam accounts for much of the 75 horsepower difference between the two engines.

10. A Cloyes single-roller timing set keeps valve timing precise amidst the immense valvespring pressure required by the solid-lifter cam. Mast advanced the camshaft to a 106.5-degree installed centerline to help recover some of the low- and mid-range torque sacrificed by the engine’s small displacement.

11. An absolute must for any serious road race machine, the Mast 388 features an ARE dry-sump oiling system. The OE-quality pan has three suction stages and one feed stage. Dry-sump systems not only make it nearly impossible to oil-starve an engine during high cornering and braking loads, but they also produce enough crankcase vacuum to improve ring seal and increase power.

12. The LS7’s unique factory dry-sump system uses an internal pump. Converting to an external pump requires plugging up the factory oil passages to prevent massive internal oil leakage.

13. Mast’s Black Label LS7 cylinder heads feature 285cc intake ports, 69cc combustion chambers, and rugged 0.750-inch-thick decks. At 0.700-inch lift, the heads move 395 cfm through the intake ports and 249 cfm through the exhaust ports.

14. Due to the high-rpm life the 388 is destined for, Mast upgraded the standard stainless steel valves to 2.200-inch titanium intake valves and 1.600-inch Inconel exhaust valves. Just like the pistons, the valves must completely reverse direction as they open and close. As such, in a high-rpm race engine, every gram of weight savings on the “valve side” of the rocker arm helps improve valvetrain durability.

15. Ensuring that the lifters stay put on the cam lobes are PAC 1.550-inch valvesprings that provide 258 psi of seat pressure and 658 psi of open pressure. They’re held down by PAC titanium retainers and locks.

16. On the “pushrod side” of the rocker arms, saving weight is secondary to reducing valvetrain flex. Consequently, the Mast 388 utilizes Isky Red Zone 0.842-inch solid roller lifters and 6.925-inch-long Smith Brothers tapered 7/16-inch pushrods.

17. After installing the factory timing cover and ATI Super Damper, the heads were torqued down to 80 ft-lb. Cometic MLS head gaskets seal the combustion chambers while ARP head studs keep the heads clamped down securely.

18. While the standard Mast 427 SS can make do with factory stamped rocker arms, the stress created by the additional spring pressure and rpm of the solid-lifter 388 are best handled by T&D shaft-mount 1.8:1 rocker arms. The lash was set at 0.020 inch.

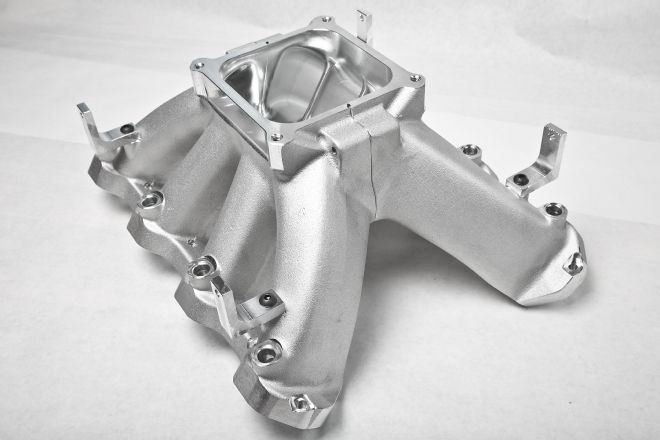

19. Compared to a factory-style composite intake manifold, the single-plane Mast LS7 unit boasts a 4500 flange and a substantial increase in runner length, runner volume, and plenum volume. The big plenum boosts top-end power while the long runners enhance low-end torque.

20. The trick, two-piece design of the Mast intake allows CNC-porting and hand-blending of the otherwise-hard-to-reach plenum and runners. The driver and passenger sides of the intake are held together by through-bolts located on the bottom side of the plenum.

21. An anodized Accufab throttle body feeds 2,000 cfm of air into the hungry 388. For EFI compatibility, it includes a TPS and an IAC valve.

22. A set of 60 lb/hr injectors provide the fuel supply for the Mast 388. They’re affixed to the intake manifold using custom Mast fuel rails.

23. With a Mast M-90 ECM controlling the fuel and spark, the 388 kicks out 723 hp at 7,400 rpm and 538 lb-ft at 5,700 rpm on Mast’s Superflow dyno. The super-efficient Black Label cylinder heads need just 24 degrees of ignition advance.