What do you do when you notice a retailer is having a fire sale on limited production racing parts? If you have the spare change, you step up to the plate and buy just to take advantage of the deal and put it in stock. That's just what a customer of Jesse Robinson's SKMFX Engines did when he spied an R3 Mopar Performance block on offer for $750. Mopar's R3 was a seriously beefed race piece, offered in a vast array of configurations based upon the production LA engine architecture. This particular block, produced with the larger 360-sized main bearing bores, two-bolt main caps, a 59-degree lifter bank angle, and featuring non Siamese bores, is one of the less desirable examples of the breed. Be that as it may, like all R3 blocks the strength is there to handle massive amounts of power reliably.

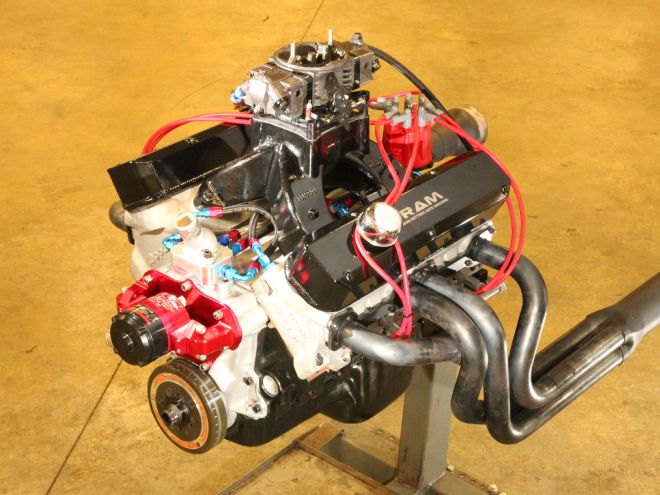

This block sat around for several years until Jesse was contacted with the aim of building a very high output street small-block for use in an A-Body Barracuda. Starting with an R-block, it doesn't make sense to shoot for the typical street power range of 400-500 hp. You can do that with any stock production block. The plan began to gel with the idea of packing the block with as many cubic inches as practical, topping it with a head and induction system that really moves the air and makes serious horsepower. That build concept happened to fit well with the annual AMSOIL Engine Masters Challenge. Since Jesse has been a long-time competitor in that event, the decision was made to build the engine to legal specs for that competition, run it at Engine Masters, and then drop it home in the Barracuda.

Bottom End Building

Jesse sonic tested the block and found a 4.040-inch bore would leave enough cylinder for a couple of future freshen-ups while maintaining good wall thickness. With that limitation to bore size, any plan for big cubic inches would have to come from the crankshaft. While 4.00-inch stroker cranks are the common upgrade for Mopar small-blocks, Jesse opted to go considerably further, with a 4.25-inch stroke crankshaft from BPE. The 4.040-inch bore combined with a 4.250-inch stroke would take the small-block's displacement to a sizable 436 cubes. The block was prepped with the usual high level of attention we have come to expect from the professionals at SKMFX, including a detailing of the oil passages, general cleanup of the casting flash, and then the final bore, hone, and decking. The two-bolt center main caps were replaced with a set of Milodon ductile iron splayed four-bolt caps. With the fully filled pan rails of the R-block, there is plenty of meat for the additional main cap fasteners to bite into.

Along with the big increase in stroke, the BPE crankshaft came with the small 2.00-inch small-block Chevy spec rod journals, which provide a broad rod selection and decreases bearing speed. The compact big end improves the inherently tight crankcase clearance of the long stroke. Scat 6.200-inch rods hang from the journals, and only a small clearance notch at the bottom of each cylinder was required to make it all fit with clearance to spare.

Filling the bores is a really trick set of Diamond custom pistons, featuring a full spherical dish for a compression ratio of 11.43:1. The pistons are cut for 0.043-inch compression rings, with lateral gas ports, and 0.927-inch Chevy spec pins to work with the small end of the Chevy application Scat rods. The pistons received Diamond's optional thermal barrier crown coating and antifriction skirt coating, as well as their CNC lightening treatment. To seal the pistons to the bores, Jesse went to Total Seal for the ring package. Even with the very long stroke and the longer-than-stock rod, the compression height worked out to a reasonable 1.275 inches. The 3mm oil ring easily fit without protruding into the piston pin bore.

Lubrication is provided by a standard Melling oil pump, while a stock truck oil pan runs without a windage tray and seals the bottom end. Of course, the truck pan will not fit the 1968 Barracuda chassis, but the deep sump and short, direct, pickup tube were well suited to the AMSOIL Engine Masters Challenge. All in all, despite the very long stroke and the race-style parts, as Jesse put it, "The short-block was very straightforward; it came together very nicely."

Heads You Win

Moving up to the top half of the engine combination, Jesse was looking for serious hardware capable of moving a great deal of air. The heads selected are truly race derived—Mopar's P4532847 W9 castings. These castings were sold in almost a dozen part numbers over the years through Mopar, with differing CNC machining targeting particular applications. The casting Jesse acquired were bare and un-machined, requiring full CNC work to create the ports, and then the details like installing seats, guides, and even the intake bolt holes. Prepping a set of bare casting like this is a daunting task. In contrast to his comments on the top end, Jesse told us, "We can talk for days about the top end. These heads came as pretty much a blank slate, and involve considerable custom machine work to get them to a usable form. With all the work and time involved, plus the specific valvetrain, the W9s are extremely pricy to run."

Jesse started by having former Engine Masters competitor and Mopar head specialist Brett Miller CNC a set of ports. Brett has several CNC programs for cutting ports into the bare W9 castings, and for this application Jesse went with the smallest port Brett had available. The fully equipped SKMFX shop then proceeded with the seat and guide installation, hand-finishing the ports, and adding the required boltholes for the intake manifold. All said, the work paid off, with airflow topping the 360 cfm mark on the intake side, and 248 cfm through the exhaust, breathing through custom 2.19-/1.60-inch valves.

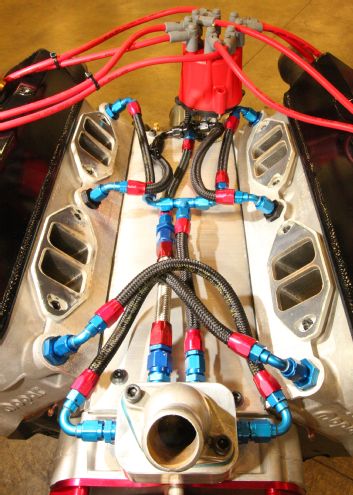

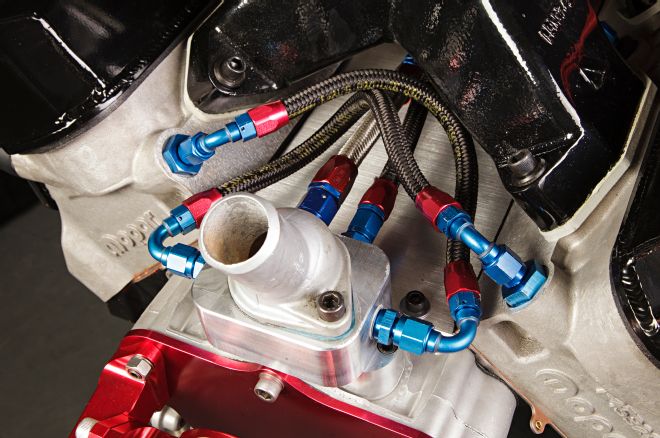

Another aspect of running these race-style cylinder heads is the plumbing for coolant return. Absent here are the standard water return ports at the front of the cylinder heads, which lead to the thermostat housing in a normal small-block Chrysler. In fact, the No. 420 intake manifold does not even have these provisions. The solution is a series of three coolant return lines plumbed directly from the heads—front, center, and rear, for a total of six lines. These were routed to a custom thermostat housing arrangement mounted to the top of the front cover. An electric CSR water pump mounts in the stock locations to circulate the cooling fluid. Jesse evaluated the novel cooling system very carefully when the engine was run in testing, "I tracked and monitored the temperature across the heads throughout testing, and it proved to be very even all the way across."

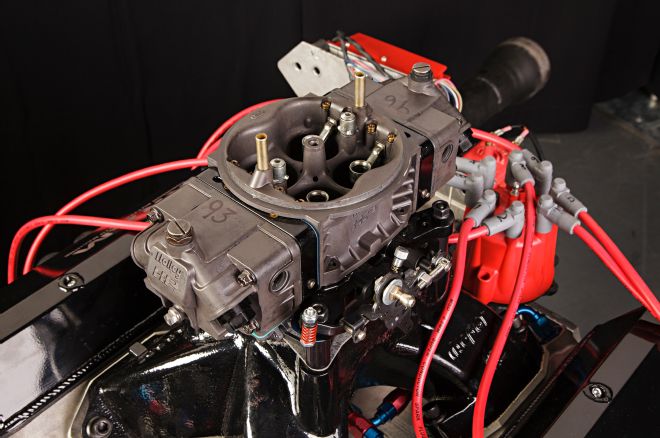

Working in tandem with the cylinder heads is a Mopar No. 420 race single-plane intake manifold. These manifolds are highly regarded in the Mopar race small-block world, and, in fact, are often adapted to Chevrolet small-blocks in certain race applications. As Jesse pointed out, "This manifold is extremely well designed, with a very nice plenum and entry into runners, and a great runner form right to the intake ports of the heads." Topping the intake is a Holley 950 Ultra HP in Hardcore Grey finish. The carb required nothing more than basic tuning.

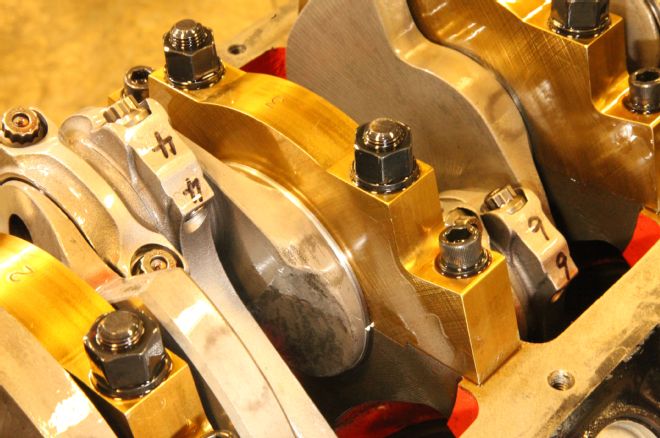

A hydraulic roller camshaft was selected both because of its longevity in a street application, and to conform to the requirements of the AMSOIL Engine Masters Challenge rules. The custom COMP Cams grind measures 250/252 degrees duration at 0.050-inch tappet rise, is ground on a 108-degree lobe separation angle, and was installed at a 104-degree intake centerline. The cam was in fact a take-out from one of Jesse's previous Engine Masters Challenge competition engines, and has been proven an effective performer. Working in conjunction with T&D's W9-specific shaft-mounted 1.75/1.7 ratio rocker system, lift at the valve works out to a hefty 0.735 inch. With that amount of valve lift, a very good valvetrain is required to maintain stability. The T&D rockers meet this requirement, and the limited-travel Johnson lifters and COMP 3/8-inch pushrods complete the package.

Jesse elaborated on the valvetrain specifics: "I bolted my parts on and it worked great. I used a PAC spring with 220 on the seat and 575 open. It was a nice spring with the micro polishing and titanium retainers and PAC locks. It was all nice stuff. I don't get too worried about the valvetrain when there are shaft rockers involved and the T&D parts are among the best. I really think there is a lot of performance to be had with an effective valvetrain. The other key component is the lifters. I like how Johnson does their limited-travel lifters. They machine a ring in a precision thickness that goes between the snap ring and plunger body that compresses it to within 0.009 to 0.010 from the bottom of the travel. They have always worked well for me."

Dyno Time

Would all the race-style hardware deliver on the promise of race level power in a street package? The dyno would tell the story here, and this big-inch small-block proved its worth. Testing in a range from 3,100 - 6,500 rpm, the torque numbers would make a big-block proud: 495 lb-ft right at the hit, rising to a staggering 629 lb-ft at a peak torque rpm of 4,800 - 4,900. That's not just big-block territory, that's 500-inch stroker big-block torque. Naturally, the horsepower side of the ledger will follow torque, and again this 436-cube combo delivered the goods, showing 664 hp coming in at a street-friendly 6,300 rpm. The beauty here is this high-powered small-block will slip into that '68 Barracuda as easily as a stock 318, but the punch will make it clear this is no ordinary small-block. Jesse's customer really didn't know what he was going to do with that bargain priced R3 block when he bought it, but Jesse definitely had some worthwhile suggestions!

On The Dyno RPM:TQ:HP: 3,100497293 3,200496302 3,300495311 3,400492318 3,500476317 3,600466320 3,700462326 3,800460333 3,900462343 4,000472359 4,100496387 4,200539431 4,300581476 4,400608509 4,500619531 4,600625547 4,700628562 4,800629575 4,900629587 5,000628598 5,100625607 5,200621615 5,300618623 5,400614631 5,500609638 5,600604644 5,700598649 5,800592654 5,900584657 6,000578660 6,100569661 6,200561662 6,300553664 6,400544663 6,500533660FAST FACTS

436ci Chrysler Small-Block

Builder: Jesse Robinson/SKMFX

Bore: 4.040-inch

Stroke: 4.250-inch

Displacement: 436 ci

Compression ratio: 11.43:1

Camshaft: COMP custom hydraulic roller

Valve lift: 0.735-inch

Duration: 250/252 degrees at 0.050 inch

Lobe separation angle: 108 degrees

Intake installed centerline: 104 degrees

Rocker & ratio: 1.75/1.7

Lifters: Johnson limited-travel hydraulic roller

Pushrod: COMP 3/8-inch dia.

Pistons: custom Diamond

Rings: Total Seal 0.043/0.043/3mm

Block: Mopar R3

Crankshaft: BPE

Rods: Scat 6.200-inch

Main journal diameter: 2.50-inch

Rod journal diameter: 2.00-inch

Bearings: MAHLE/Clevite

Cylinder head: Mopar W9

Intake port flow: 363 cfm

Exhaust port flow: 248 cfm

Intake valve diameter: 2.19-inch

Exhaust valve diameter: 1.600-inch

Head gasket: Cometic MLS

Intake manifold: Mopar No. 420

Carburetor: Holley 950 Ultra HP

Header: Schoenfeld 1 7/8 inch

Ignition: MSD

Damper: ATI

Water pump: CSR electric

Oil pan: stock truck

Oil pump: Melling standard volume

Fuel: VP 101 unleaded

Motor oil: AMSOIL 10w-30

1. Although Jesse Robinson of SKMFX Engines started with a Mopar R block, the cylinders in this non-Siamese version were finish machined to 4.040 inches, a bore no larger than a production 340. The huge increase in displacement came via a 4.25-inch stroke crank from BPE.

2. The R3 block was available with four-bolt mains, but this particular variation came through with a two-bolt arrangement. To add beef, the block was modified to accept Milodon splayed four-bolt caps.

3. Teaming up with the crank to complete the internal assembly were a set of Scat I-beam rods, featuring small Chevy specs of 2.00 inches at the big end and 0.927 inch at the piston pin. The pistons are custom Diamond pieces, using a spherical dish shape for a compression ratio of just under 11.5:1. Rings are from Total seal in a 0.043/0.043/3mm pack. Note the lateral gas ports and coated crown and skirt.

4. Even with the very long stroke, the crankcase clearance was a minor issue due to the small 2.00-inch journal and compact capscrew rods. A modest notch at the bottom of the bores was all that was required to make it fit.

5. A stock 360 truck pan holds the AMSOIL 10w30 synthetic lube. Like the block, the inside of the pan is painted with electric motor winding varnish for a smooth, slick, sealed surface.

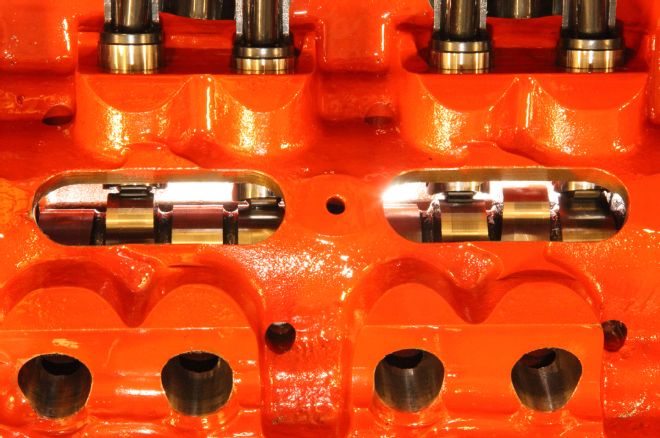

6. Working the valves is a custom COMP hydraulic roller cam, cut with 250/252 degrees duration at 0.050 and a 108-degree lobe separation angle. The cam was installed at 104 degrees intake centerline, and runs with Johnson limited-travel hydraulic roller lifters.

7. Mopar W9 cylinder heads top the short-block. These started as bare unfinished castings. Large 2.190-/1.600-inch valves fill the chamber to the limit.

8. The Mopar W9 heads essentially have no ports as delivered, and were sent to Bret Miller to have the ports CNC machined into the castings. Bret has several variations of port programs developed for these heads. These intake ports as finished by SKMFX and flow over 360 cfm.

9. The T&D shaft-mounted rocker system is the last word in stability. The rocker ratio is 1.75/1.70:1, giving 0.735-inch lift at the valve.

10. It doesn't get much better in single-plane intake manifold design than the Mopar No. 420 race intake. Other than a deep port match, very little custom porting work was required with this manifold.

11. With the production 9.560-inch—deck block and the raised port location of the W9 heads, spacers were required to fit the intake manifold. Note the bungs for coolant return tapped into the cylinder heads. The W9 does not have the production style coolant return provisions at the front of the heads.

12. A Holley 950 Ultra HP carb deliver the air and fuel. This carb was run in essentially box-stock configuration, with only tuning calibration changes required.

13. Beneath the intake manifold, we can see the external coolant lines which route coolant from the front, center, and rear of each head. The -6 lines fit in the space below the installed manifold. Note the custom valley tray that seals the top of the block.

14. The coolant lines are routed to a custom-built thermostat housing mounted to the front cover of the engine. Retrieving coolant from the full length of the head, the system results in a more uniform temperature gradient.

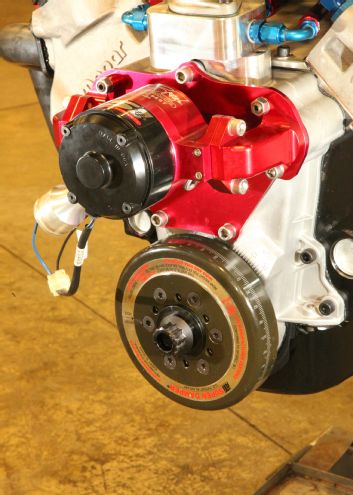

15. At the front of the engine we find a CSR electric water pump fitted to the production LA-series small-block front cover. The crankshaft damper is from ATI, known by racers and engine builders alike as one of the best in the industry.

16. Handling the spent gases is a set of Sprint Car–style Schoenfeld 1 7/8-inch headers. The header flanges and bolt pattern of the W9 head is unique, and does not interchange with any production small-block Mopar cylinder head.

17. At the 2014 Engine Masters Challenge, this big small-block did not get to show its full potential, due to a stripped intermediate shaft gear. Despite the problem, the team of Jesse Robinson, Joe Rutters, Bryan MacDonald, and Ron Maclean are always outstanding representatives of Mopar muscle at the competition.

18. Dyno testing showed this street combination of race-style parts delivers the goods, with an incredible 629 lb-ft of peak torque showing at 4,800-4,900 rpm, and a peak output of 664 hp at 6,300 rpm. That is truly big-block power from a small-block package.