In keeping with this issue’s how to daily-drive a project car theme, here’s a look at the temporary engine swap we have coming up for our 1966 Malibu. The Malibu’s original 220hp 283 is living on borrowed time and the last thing we want to do is get caught without cool wheels to cruise.

Because nothing will have to be changed with the existing transmission, driveshaft, or rearend this is an engine swap that can be completed during the course of one weekend. That said, there are a few snags that can occur, so we’ve included a few tips on how to avoid the pitfalls.

And note we say temporary engine swap because not in a million years would an ’80’s era 305-inch small-block be our ultimate dream engine, but let’s take a look at why it made sense for the here and now.

Adhering to time-honored hot-rodder traditions when it comes to engine choices, the first rule is you run what you got. And what we got is an extremely low-mile, pre-1986 305 long-block a friend bought from Wayne’s Engine Rebuilding of Riverside, California, and then shortly after totaled his car. For those unfamiliar with a 305, it’s basically a two-bolt 350 engine with a cylinder bore smaller than the original 265-inch small-block introduced in the 1955 model year.

Interestingly, with modern high-performance parts available from companies like Edelbrock and Performance Distributors reaching over one horsepower per cubic inch with a 305 small-block is a cinch. As a rule, the preference is towards an oversquare configuration such as a 283 punched to 301 because those engines rev quickly, so it will be interesting to see what a hopped-up small-bore long-stroke engine will behave like.

No matter how the 305 turns out, the good news is that most high-performance parts installed on a 305 can be transferred to another displacement small-block, such as a 283, 327, or 350.

1. The first step to any Chevy engine hop-up is to identify what model and displacement the engine is, so the right parts can be ordered. The DTW suffix found on the passenger side deck of the block identifies this engine as a pre-1986 305 engine.

2. Next in line is to identify the cylinder heads. The 3766450 cast on these heads identify them as low-performance two-barrel cast-iron heads with 1.72-inch intake valves. Switching to Edelbrock aluminum heads will save weight as well as wake up the 305.

3. In order to change the camshaft, the harmonic balancer must be removed. We made sure the three-bolt puller was perfectly aligned to pull directly outward. First, a rap with a hammer then an air impact wrench works best.

4. Next, the timing cover was unbolted and popped off with a putty knife to separate it from the block. Notice the timing marks on the timing gears are positioned at 6 o’clock and 12 o’clock.

5. Replacing the stock performance single-row timing chain with the high-performance Edelbrock double-roller timing chain set (PN 7800) eliminates chain stretching and offers three settings to advance or retard cam timing. Good for up to 6,500 rpm.

6. The stock flat tappet hydraulic lifters must be pulled upward to remove them from their bores before removing the cam.

7. A long 5/16 coarse thread bolt works great as a handle to initially pull the camshaft out of the block. Holding the cam flat in alignment with the cam bearings eases removal.

8. The deck must be absolutely free from leftover head gasket material before installing the new Edelbrock heads. A sharp gasket scraper or a single-edge razor blade work equally well.

9. The head bolt threads in the block should be checked for condition and chased with a tap if there are any burrs or bad (buggered) threads.

10. ARP makes the best bolts and Edelbrock uses genuine ARP bolts for its head bolt kits. Applying ARP Ultra-Torque assembly lube reduces tension and preload scatter, ensuring consistent torque readings during engine assembly.

11. It will be few weekends before this engine will get built (assembled). Test fitting beforehand ensures there will be no surprises when the time comes to knock it out in a weekend.

12. Edelbrock red roller rocker arms. There’s horsepower to be found by decreasing valvetrain weight and friction, plus changing to a performance 1.5:1 rocker arm ratio.

13. Back in the day, the mere mention of a roller cam meant it was a badass engine. There’s more than just installing a roller cam with lifters to convert to a roller cam. Using an Edelbrock retro-fit roller lifter kit in our 305 means the entire roller valvetrain has been engineered to be compatible. Even the valvesprings in the Edelbrock heads are correct.

14. This is a 600-cfm carb, but even with its small 305-inch displacement the larger (hotter) Edelbrock roller cam should enable the use of a much larger 750-cfm Edelbrock AFB carburetor. Future testing; we’ll have to try it and see what happens.

15. Be aware of accidently restricting fuel flow. Available from Summit Racing, the use of fuel-injection hose with its much heavier wall makes it a lot less likely to kink a fuel line and starve the carburetor.

16. Have the right fuel pump rod for a roller cam when using a mechanical fuel pump. A time waster if ignored, make sure to have fuel line fittings before starting the job.

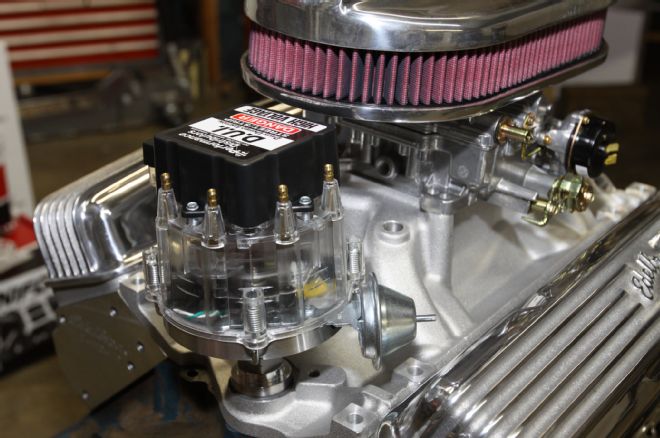

17. More hidden horsepower can be found by curving the distributor to match the cam. We gave Performance Distributors the specs for the Edelbrock cam and they calibrated the DUI advance curve to 22-degrees at 3,000 rpm. A clear cap simplifies setting initial timing. We’re using Live Wires for plug wires.

18. Properly timed, the vacuum advance module usually ends up pointing to 7 o’clock. After timing the engine to where it runs best, stamping a reference point with a center punch into the intake manifold is a good practice.

19. A proven combination in many past projects, the tiny, lightweight Dyna-Batt with a high-amp output Mr. Amp alternator keeps the DUI coil saturated as well supplying accessories and starting the engine. Try it, you’ll like it.

20. With a roller cam there’s no need to worry about having zinc (ZDDP) in the engine oil. When the 305 goes in we’ll switch from AmsOil Z-Rod to AmsOil Signature Series.