In these tech articles on cams, heads, and (in this case) a Kenne Bell supercharger, we generally wait until the last moment to reveal the dyno results, but since we know you all skip right to the graph, we will cut to the chase. The 2015 Mustang is awesome and is powered by an upgraded version of the already impressive Coyote motor. Run on the DynoJet chassis dyno, the stock (manual-trans) Mustang produced 385 hp and 378 lb-ft of torque at the wheels. After the addition of the standard (49-state) kit, which included the 2.8L twin-screw supercharger running 10 psi of boost, the peak numbers jumped to 640 hp and 507 lb-ft of torque (a 50-state kit is pending). In typical twin-screw fashion, the torque curve resembled more of a torque plateau, as the immediate boost response offered torque by the truckloads.

Now that we have spilled the beans, is this the end of what would be a very short story? This is just the beginning. The simple test of the standard supercharger kit only answers one question—what did it do? The more important question should be how did it do that, and then the follow-up questions should ask how much more (and why)?

Adding boost to any Coyote motor is always rewarding, especially if it comes in the form of an efficient twin-screw supercharger kit from Kenne Bell. As much as we love boost, the positive pressure is only a small part of a very important dynamic equation. In short, so much more goes into the kit than the ability to add 10 psi to your Coyote motor.

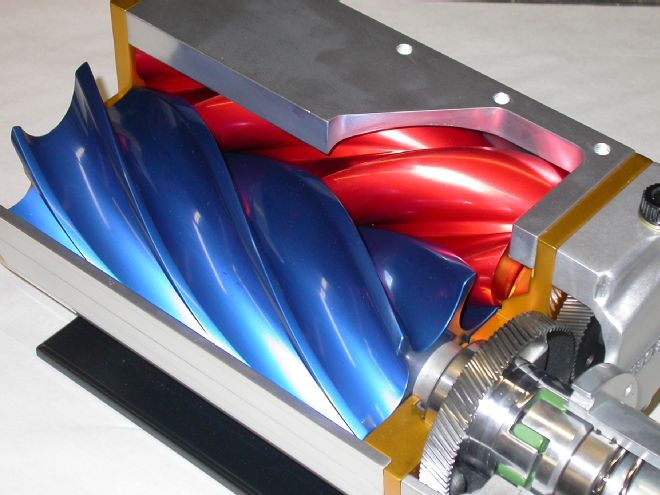

Starting with the supercharger, the twin-screw design from Kenne Bell featured a billet casing to improve strength. Case strength is an important design feature, especially at elevated rotor speeds and boost levels. Improved case strength means the critical tolerances a can be tighter to improve the flow rate and boost potential of the supercharger. On lesser cases, the required tolerances ultimately limit rotor speed and boost levels, thereby limiting maximum power potential, lest damage occur. Combine this strong case with an industry-leading 4x6 rotor pack, and you have superchargers capable of amazing power and efficiency. Toss in a variety of different displacements (from 2.8L to 4.7L), and Kenne Bell can tailor the supercharger to the needs of even the wildest of Coyote motors, whether you are looking for 700 or 1,700 hp (or more).

Obviously a great deal of technology goes into the supercharger itself. We have only scratched the surface. Additional features employed on the twin-screw included Liquid Cooling, Seal Pressure Equalization, and blower configurations designed specifically for higher boost levels. Not to be confused with the air-to-water intercooler (capable of supporting 1,500 hp), the Liquid Cooling system was designed to equalize the temperature differential between the cool (inlet) and hot (discharge) sides of the supercharger. The internal compression inherent in the twin-screw increased the inlet air temperature and therefore the working temperature of the supercharger components (and gear oil). This differential means the tolerance on the hot side would be different than those on the cool side. Liquid Cooling was designed to minimize this differential to equalize operating temps on both sides to further decrease the inlet air temps and improve longevity.

Another trick supercharger feature offered by Kenne Bell is a system called Seal Pressure Equalization. The twin-screw design features a front seal to separate the gearbox from the rotor pack. The problem is that this front seal must resist the internal pressure supplied by the supercharger. The greater the boost levels, the more pressure applied to the seal. Recognizing the potential of the situation, Kenne Bell designed the Seal Pressure Equalization (SPE) system, which effectively equalizes the pressure on both sides of the seal to eliminate the differential. Using a pressure relief system, the pressure is vented from the back of the seal to the inlet tube or air filter. Relieving the pressure eliminates the chance of seal failure, thereby preventing rotor pressure from entering the gearbox. Liquid Cooling and Seal Pressure Equalization can be combined with the standard of high-boost H-series blower configurations to maximize boosted performance.

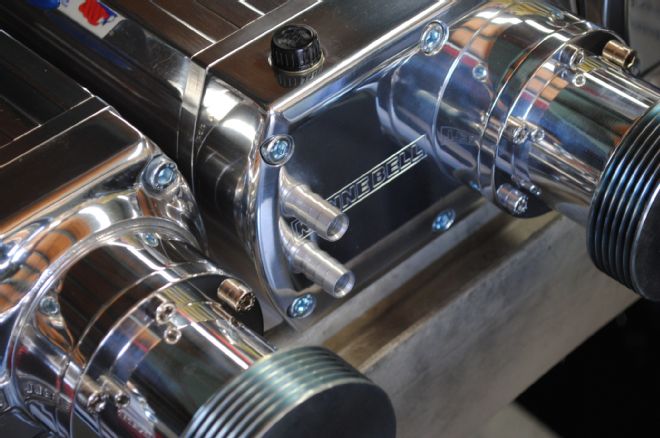

While the twin-screw blower gets all the attention, the reality is that the supercharger is only as good as the inlet system. Recognizing that boost out of the blower was in direct proportion to the airflow into the blower, Kenne Bell went to great lengths to supersize every component of the inlet system, from the air filter right through to the Mammoth intake manifold feeding the blower. Any inlet restriction before the blower will manifest itself in a drop in boost pressure out of the supercharger. This includes the manifold, throttle-body, MAF, and air intake. Replacing the restrictive factory air box was a dedicated cold-air intake and MAF assembly. The 2015 Kenne Bell Coyote kit featured a massive 4 1/2-inch system (flowing 2,000 cfm) designed to maximize unrestricted, ambient airflow to the throttle-body. Resizing and repositioning the MAF naturally necessitated recalibration of the ECU, but the supplied supercharger program included the necessary changes. Finishing up the high-flow induction system, the Mammoth intake was designed to accept the 168mm oval throttle-body capable of flowing 2,150 cfm. Need more? Kenne Bell offers a dual 106mm BIGUN throttle-body assembly for serious race applications.

Now that we have discussed the standard 2015 Coyote kit and the technology that went into it, it’s time to talk potential. Sure, adding a blower will improve the power, and all the technology that goes into the Kenne Bell kit sounds great, but what does it all mean? Well, fellow Ford fanatics, what all this means is that while the standard kit will add 255 hp at 10 psi, there is a ton of power left in the system. Even the 2.8L supercharger is capable of supporting over 1,000 hp on the right application. Running boost only (no other engine mods) with the base 2.8L kit produced as much as 813 hp at 21 psi of boost, but it was necessary to upgrade the 47-pound injectors to a 130-pound set from Injector Dynamics and augment the stock fuel pump flow with a 20V Boost-A-Pump. Because Ford saw fit to include a high-flow fuel system, no BAP was required for the standard kit running 10 psi. Need more? Kenne Bell offers blowers as big as 4.7L capable of supporting over 2,000 hp! Thanks to the supplied motor mounts, the 2.8L-3.6L all fit under the stock hood but if you are thinking about the big-boy blower and dual throttle-body, BIGUN intake, that race motor is going to require a little extra hood clearance.

01. The 2015 5.0L Coyote-Powered Mustang has a lot going for it. Thanks to Kenne Bell, you can add boost to that list.

02. The S550 is no slouch from the factory; the stock (stick) Mustang produced 385 hp and 378 lb-ft of torque at the wheels.

03. The standard kit for the 2015 5.0L Mustang featured a 2.8L, twin-screw supercharger capable of supporting 1,000 hp.

04. To maximize airflow and boost out of the twin-screw blower, the Kenne Bell kit included the Mammoth intake manifold.

05. Each supercharger kit featured a bypass valve to route the charge air back to the inlet side of blower under cruise and lift-throttle conditions. This system was designed to greatly reduce parasitic loss and inlet air temps.

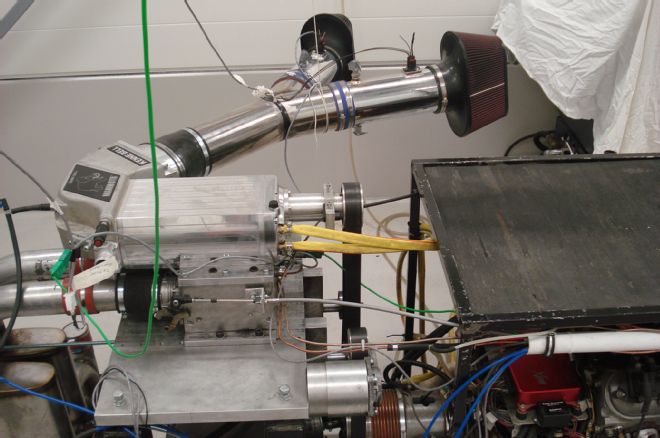

06. Kenne Bell spent endless hours developing and improving its superchargers on not only the chassis dyno but also on the company’s own supercharger dyno.

07. Adding to the development list is the time spent on the airflow bench maximizing the flow rates of the intake manifold, intercooler core, and induction system.

08. Recognizing the need for a steady supply of cold air, the Kenne Bell supercharger kit featured a 4 1/2-inch cold-air/MAF intake system. Hot air and the restrictive factory air intake have no place on a supercharged Coyote.

09. Kenne Bell combined the massive air intake system with a 168mm oval throttle body. Every effort was made to maximize airflow to the blower.

10. Boost supplied by the twin-screw supercharger is a function of the blower speed versus the engine speed. The standard kit featured a (six-rib) 3 7/8-inch blower pulley, but boost pressure (up to 20 psi) was adjustable using different pulley sizes.

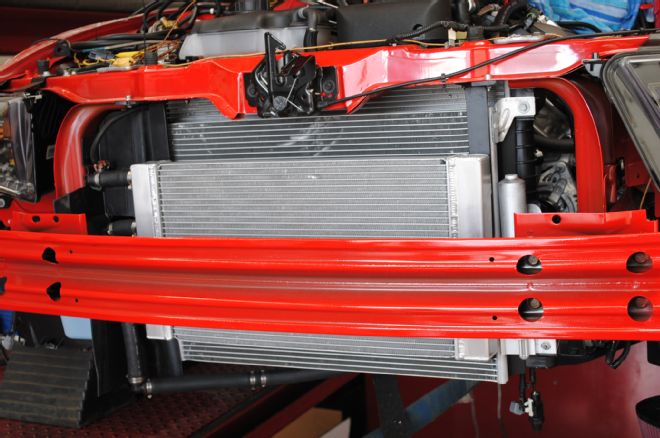

11. To keep the charge temps down and power up, the Kenne Bell supercharger kit included a very efficient air-to-water intercooler. The core was revised to maximize flow and cooling, with enough capacity to support 1,500 hp.

12. The air-to-water intercooling system included a dedicated pump, reservoir, and giant heat exchanger.

13. Though the standard kit featured a black satin blower, options like polishing, Liquid Cooling, and Seal Pressure Equalization are also available.

14. Equipped with the standard (49-state) kit pumping out 10 psi, the supercharged Coyote produced 640 hp and 507 lb-ft of torque.

15. If the 1,000hp 2.8L isn’t enough, Kenne Bell offers twin-screw blowers ranging from the 2.8L to a massive 4.7L. Using the supplied motor mounts, the 2.8L, 3.2L, and 3.6L all fit comfortably under the stock hood.

16. If you have a modified Coyote and are looking for maximum power, Kenne Bell can set you up with a 4.7L equipped with the company’s dual 106mm throttle body and BIGUN intake manifold.