If you recall, last month we yarded a greasy, iron-block 6.0L from the people at LKQ and proceeded to bolt in a Scat stroker 4.00-inch-long arm, Scat I-beam rods, and a set of Mahle forged pistons. To keep it simple, we pitched the EFI in favor of an Edelbrock carbureted Victor Jr. intake, a Holley carb, and an MSD ignition conversion. When the carb cleaner fumes hit us, we decided to name the engine Lester Scruggs (L.S., get it?). The goal last month was to show how easy is it to assemble one of these engines. If this is a taste of future horsepower and how easy it is to make, we're all for it.

Les is more! We had great expectations that our first LS engine build would be successful, and 560 hp and 510 lb-ft is plenty strong for a pump gas performer.

Les is more! We had great expectations that our first LS engine build would be successful, and 560 hp and 510 lb-ft is plenty strong for a pump gas performer.

This month, we bolted Lester to Ken Duttweiler's engine dyno and unleashed the hounds to measure how much twist came out of the other end. Secretly, we thought 575 hp on pump gas was achievable from our iron 404. But we compromised the compression a little because we also want to bolt on a blower in the near future, so now we have to live with 9.8:1. We still made an impressive 560 hp, so now our rally cry is, Les is more!

The big leverage point for the LS series of engines has always been excellent cylinder heads. Every LS production head features no worse than 15-degree valve angles (the standard small-block Chevy valve angle is 23 degrees), and more recent LS performance variations have pushed that out to 12 degrees. So our testing started with a bone-stock set of 6.0L heads. Our pal Richard Reyman at West Coast Racing Cylinder Heads (WCRCH) cleaned the original heads and pronounced them fit for duty with new seals and a set of Comp beehive valvesprings. Next, Reyman suggested testing a set of his CNC-ported production 6.0L heads as a simple upgrade that would retain the cathedral-port-style heads.

Our ultimate goal, however, was to test Lester with two different sets of L92 heads. For those of you not familiar with GM engine nomenclature, the L92 variable valve (VVT) timing engine first appeared in the '07 Escalade and is now used in many current SUVs and trucks. Bolted to a 6.2L engine with a 4.03x3.62-inch bore and stroke, L92 heads are prized for their very large, rectangle-shaped intake ports connected to huge, 2.165/1.590-inch valves. Because of the oversized intake valve, these heads can only be used on 4.00-inch-and-larger-bore engines, which makes them perfect candidates for Lester's 4.010-inch bore.

We've included the flow bench numbers for all four sets of heads so you can follow the bouncing ball through the whole process. After our testing, it appears the stock L92 heads may need some additional help on the exhaust side for ultimate power. Even without porting, these heads offer excellent power potential. Our pals at Scoggin-Dickey sell them for just under $900 per pair, but you will also need the L92-specific rockers, stands, and bolts to make it all work, which will up the price to just under $1,200. That's a screamin' deal.

With all this going for these heads, we had to try them. You may recall we've tested these castings once before. Back in the May '07 issue ("550 HP for Under $4,900") we ran a set on a stock 6.0L short-block with a Comp hydraulic roller cam, a single-plane intake, and an MSD ignition conversion. As the headline reads, we made 551 hp at a somewhat stratospheric 6,800 rpm. We figured if a 364ci engine could make this kind of power, then adding another 40 ci would make a lot more. Our results were a little different than we'd expected, but still rewarding.

Carb cleaner.

Big Ports, More Flow

For years, we've been talking about the potential advantages of smaller intake ports that enhance intake velocity in an effort to make great torque for street engines. However, with the LS series of engines, these L92 and LS3 heads with their larger, rectangle-shaped intake ports seem to take exception to that concept when used on large displacement engines. If we had really looked at our own flow testing during development, we would have noticed that the CNC-ported cathedral heads offered a much better exhaust-to-intake-flow (E/I) relationship than the L92 heads. Looking at the E/I for the ported L92 heads reveals that the flow relationship indicates a need for more exhaust duration to help top end power. When we get to the actual dyno results, the lack of good exhaust port flow could be used to explain why the engine didn't quite make the power we thought it should.

After baselining the engine with the stock 6.0L heads, we bolted on a set of ported 6.0L castings from West Coast Racing Cylinder Heads. Owner Richard Reyman has this program dialed in and says it offers some excellent flow improvements over the stock heads while retaining the stock valve sizes.

Flow Data

Valve Lift

Stock 6.0L

Ported 6.0L

E/I Percent

After baselining the engine with the stock 6.0L heads, we bolted on a set of ported 6.0L castings from West Coast Racing Cylinder Heads. Owner Richard Reyman has this program dialed in and says it offers some excellent flow improvements over the stock heads while retaining the stock valve sizes.

Flow Data

Valve Lift

Stock 6.0L

Ported 6.0L

E/I PercentThe stock 6.0L and WCRCH-ported versions come with a 70cc chamber and 2.00/1.55-inch valves. These flow numbers came from West Coast Racing Cylinder Heads and were tested on a 4.030-inch bore at a test depression of 28 inches.

Valve Lift Stock L92 GMPP Ported L92 E/I PercentThe GMPP CNC-ported heads come with a 70cc combustion chamber and stock 2.165/1.590-inch valves. Both sets of L92 heads were tested on JGM's SuperFlow 600 flow bench with a 4.060-inch bore adapter at 28 inches. Intake port volume on the CNC versions is 279 cc.

Cam Specs Camshaft Duration (Advertised) Duration (At 0.050) Lift (Inches) Lobe Separation XER281HR, intake 281 232 0.595 112 54-428-11, exhaust 283 234 0.598 LS1 277 LRHR, intake 276 227 0.614 113 54-458-11, exhaust 284 235 0.621Valve lift numbers are based on the stock LS 1.7:1 rocker ratio.

Dyno Testing

We began testing with the stock 6.0L heads to which we added a set of Comp beehive valvesprings and Comp 0.080-inch-wall Hi-Tech pushrods to ensure the valvetrain would not suffer from separation anxiety. This first test revealed what we gained by just bumping the displacement along with a slightly more aggressive camshaft. Our original 6.0L engine combination with a GM Hot cam made 450 lb-ft at 5,000 rpm and 483 hp. These same stock 6.0L heads surprisingly didn't improve peak horsepower, but the torque jumped 30 lb-ft at the peak, which is what you'd expect from 40 more cubic inches. Next, we bolted on the WCRCH-ported 6.0L heads. This time, we saw a gain in overall power. Torque improved mostly after 4,000 rpm, gaining 19 lb-ft at the peak to a satisfying 505 lb-ft. Now it was time for the big boy heads.

To finish out the dyno installation, we had to add an external oil filter to the Moroso oil pan, bolt on the Kooks 1 7/8-inch headers, and plumb the exhaust with a pair of Borla 3-inch stainless mufflers. The last step was to add the Quaker State Q synthetic 5W-30 oil.

To finish out the dyno installation, we had to add an external oil filter to the Moroso oil pan, bolt on the Kooks 1 7/8-inch headers, and plumb the exhaust with a pair of Borla 3-inch stainless mufflers. The last step was to add the Quaker State Q synthetic 5W-30 oil.

Our first pull on the dyno with the bigger L92 heads fell short of 530 hp. Torque was up, which was encouraging, but the peak horsepower was disappointing. Our first move was to add a Wilson carburetor spacer to see if the power would improve. We gained 3 or 4 horsepower but not nearly enough. Next, we swapped in a Comp cam with more lift but a touch less intake duration. This test, after some tuning, delivered a peak of 550 hp, which was more to our liking, along with a max torque of 516. This also included a Wilson carburetor spacer.

The final test saw the GMPP CNC-ported L92 heads bolted in place. As quickly as the swap was completed, we were back making noise, but since the flow bench numbers revealed that the major flow increases occur above 0.600 inch valve lift on the ported L92 heads, this test didn't promise a huge increase. True to form, we gained 11 hp, bringing the peak horsepower to 561 at 6,400 rpm.

Test Data

Test 1 equipped the 404ci motor with stone-stock 6.0L heads and valves, adding Comp 26918 valvesprings along with the Edelbrock Victor Jr. cathedral-style intake manifold, a Holley 950 HP carburetor, a set of 17/8-inch chassis headers, and a pair of 3-inch Borla mufflers.

To give Lester a little luster, we dressed him up with a Kwik Performance alternator mount that eliminates the power steering pump. The kit bolts to the cylinder head and uses either a truck or LS1 Camaro alternator. Kits are available to work with a Corvette, Camaro, or truck balancer.

To give Lester a little luster, we dressed him up with a Kwik Performance alternator mount that eliminates the power steering pump. The kit bolts to the cylinder head and uses either a truck or LS1 Camaro alternator. Kits are available to work with a Corvette, Camaro, or truck balancer.

Test 2 used the same equipment except for the addition of a set of WCRCH CNC-ported 6.0L heads and the same springs.

Test 3 added a set of stock L92 heads along with the bigger Comp cam. The larger L92 intake ports also required an Edelbrock Victor Jr. L92 single-plane intake manifold. We retained the 950-cfm carburetor but added a 11/2-inch Wilson tapered carburetor spacer.

Test 4 added the GM Performance Parts CNC-ported L92 heads. The rest of the components remained the same as in Test 3.

What We Learned

The biggest surprise of the day was the torque improvement with the larger cylinder heads. When we originally tested the L92 heads on the 6.0L engine (May '07), these big castings killed the torque. But when we bolted these same heads to the 404ci engine, the torque exceeded that of even the WCRCH-ported 6.0L heads. Note how the average torque for both big port heads exceeds even the ported cathedral head by no less than 4 lb-ft. While we didn't achieve our 575hp goal, we did see an amazing 81 peak-to-peak horsepower improvement over the stock 6.0L heads.

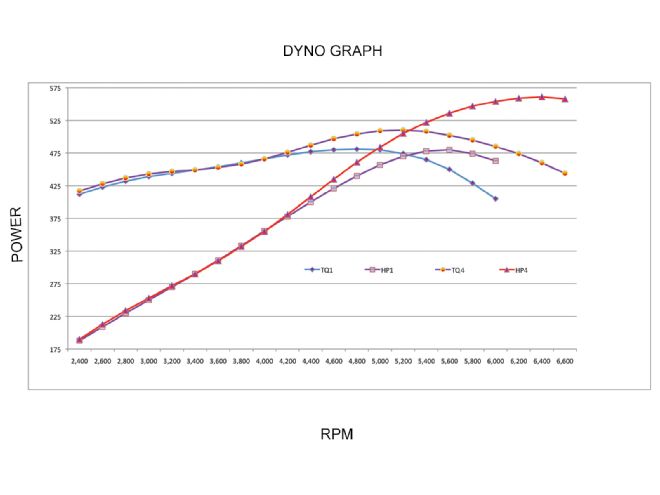

This graph shows the major torque and horsepower differences between the stock 6.0L heads and the GMPP-ported L92 castings.

This graph shows the major torque and horsepower differences between the stock 6.0L heads and the GMPP-ported L92 castings.

While the CNC-ported L92 heads at first glance don't appear to be worth the additional cost over the stock L92 castings, we didn't really give these heads a chance to succeed. We would need to add a camshaft with another 6 to 8 degrees of duration and valve lift upward of 0.670 inch to take full advantage of what these heads offer. However, a bigger cam would definitely hurt the torque and make street driveability more of a compromise. One solution would be to improve the exhaust port flow on the stock L92 heads. The exhaust flow numbers on the WCRCH-ported 6.0L heads already outflow the CNC-ported L92 heads, and the L92 stock exhaust ports are supposed to be better than the stock 6.0L versions. It's a good bet that a stronger exhaust port would allow the engine to make more peak power without sacrificing the torque, and we'd have more horsepower without having to spend big money on expensive heads.

After the test, we dug a little deeper in the Comp Cams catalog and discovered a 281LRR HR13 cam that uses a 231-degrees-at-0.050 intake but adds a much longer duration exhaust at 247 degrees at 0.050 with 0.617/0.624-inch lift. This cam would probably carry the power out another couple hundred rpm and improve power at the peak. If you are considering replicating our combination, this is the cam we'd choose.

Finally, to put our 560 hp in perspective, we plugged the power into the Quarter Jr. dragstrip simulation program using our 3,200-pound Orange Peel '66 Chevelle running 3.55 gears and a 200-4R trans. The program spit out a low-11-second pass at 122 mph, assuming we could actually harness all this power. Sounds like fun.

Parts List Description PN Source Price Edelbrock Victor Jr., L92 28457 Jegs $349.99 Kwik alternator kit, Camaro K10194 Kwik Performance $167.00 GMPP L92 stock heads, pair 12582713 Scoggin-Dickey $899.90 GMPP L92 CNC heads, pair 88958698 Scoggin-Dickey $1,099.90 GMPP racing lifters 88958689 Scoggin-Dickey $226.85 L92 rocker, intake (8) 12569167 Scoggin-Dickey $95.84 L92 rocker, exhaust (8) 10214664 Scoggin-Dickey $98.80 L92 rocker support (2) 12600936 Scoggin-Dickey $15.92 Rocker arm bolt (16) 12560961 Scoggin-Dickey $72.80 Comp 281HR hydraulic roller 54-428-11 Summit Racing $354.75 Comp 277LR hydraulic roller 54-458-11 Summit Racing $396.95 Comp 281LRRHR13 roller 54-469-11 Summit Racing $396.95 Comp valvesprings 26918 Summit Racing $174.95 Comp retainers, steel 1772-16 Summit Racing $153.95 Comp pushrods, Hi-Tech 7955-16 Summit Racing $115.75 Edelbrock Victor Jr., LS1 29087 Summit Racing $269.75 Holley carburetor, 950 cfm 0-80496-1 Summit Racing $714.95 Edelbrock Victor Jr., LS1 29087 Summit Racing $269.75 Edelbrock headers, LS1 65073 Summit Racing $519.95 Autolite race plugs AR474 Summit Racing $21.52 MSD truck plug wires 32829 Summit Racing $68.95 Wilson tapered spacer, 1 1/2 004130 Summit Racing $178.95 ARP metric studs 400-8034 Summit Racing $151.95 WCRCH ported 6.0L head WCCH-6.0L West Coast RCH $1,575.00* *Requires core-$1,865.00 outright with valves and springs