Q:

I have a 1970 SS Chevelle with a big-block 496. It has Edelbrock oval-port heads with bowl and port work, along with a Performer intake (gasket-matched) and a Rolling Thunder hydraulic-roller cam (PN 2262). Compression is around 10:1. The car weighs in at 3,800 pounds with me in it. It has 315/60R15 tires, turning them with a TH400 trans and 3.90:1 gears. It has a 3,800-rpm stall-speed converter in it now, but is on the road a lot more than at the track. I foot-brake it at the track at 2,000 rpm; it starts to push through the brakes much above that. I’m looking to get more driveability out of it and still be able to launch it at around 2,000 rpm.

Michael Riddell

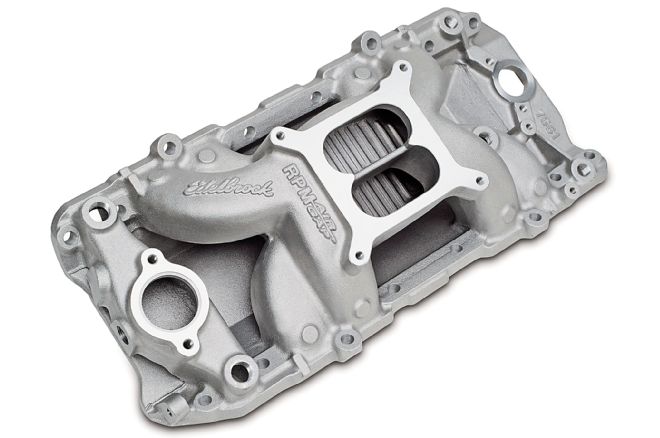

The Performer RPM or Air-Gap 2-O (shown) generally produces more midrange torque than a single plane, at the price of a tad less top-end power. That generally makes them preferable for a primarily street-driven car. They’re good to go through at least 6,500 rpm. Hood clearance permitting, experimenting with open spacers may extend that higher. A standard low-rise Performer generally flattens out by 5,500 rpm.

The Performer RPM or Air-Gap 2-O (shown) generally produces more midrange torque than a single plane, at the price of a tad less top-end power. That generally makes them preferable for a primarily street-driven car. They’re good to go through at least 6,500 rpm. Hood clearance permitting, experimenting with open spacers may extend that higher. A standard low-rise Performer generally flattens out by 5,500 rpm.

A:

Mike, your cam is Edelbrock’s biggest hydraulic roller. PN 2262 fits 1996-and-later Gen VI big-blocks; PN 2261 is for traditional 1965–1995 Mark IV and Gen V big-blocks—but either way, the lobe specs are identical at 112 degrees.

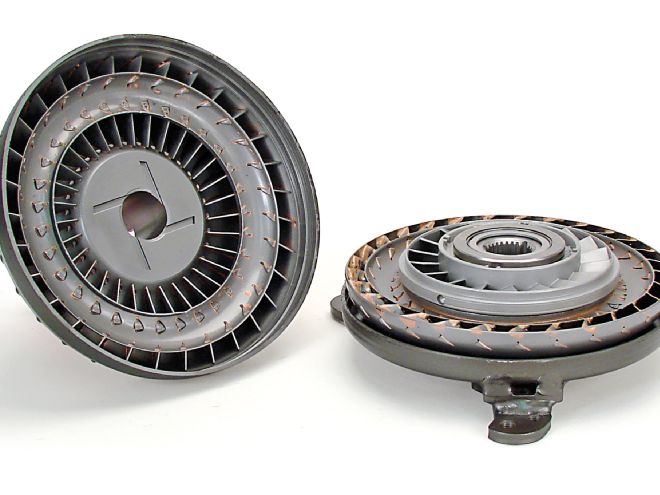

Normally, a pretty high-stall torque converter would be needed to match the cam’s operating range, but—as you’ve surmised—while a 3,800-rpm stall may be preferred for track use, it’s not very fun to drive around with on the street. The saving grace is your fairly steep 3.90:1 rear gear ratio combined with a 496ci big-block’s inherent ample torque output. With the torque multiplication provided by a TH400 transmission’s 2.48:1 First gear, you’re looking at about a 9.7:1 final drive ratio off the line—it’s no wonder the car starts “pushing” over 2,000 rpm when you foot-brake it. Collectively, these factors permit backing off to about a 3,000–3,300-rpm stall-speed converter. In TCI’s line, that would be its StreetFighter 10-inch converter series (PN 241000 for a TH400). Although it’s advertised as having a 3,000-rpm stall, with a big-block’s big torque, it should flash-stall higher to around 3,300–3,400 rpm at wide-open throttle. Lowering the effective stall should make the car behave much better on the street, and it should still foot-brake at 2,000–2,200 rpm. For track days, you might consider a Hurst Roll Control (PN 1745000)—then (provided engine torque doesn’t exceed the holding capacity of the fully locked front brakes) you can leave at an rpm level closer to the unit’s true stall speed.

But drop down even more to something with less than 3,000-rpm stall speed and you might have problems due to the size of the cam. Yeah, we’re back to the cam again. It’s kind of leading the rest of the combo around by its nose. Edelbrock normally recommends this cam for use with its big Victor Jr. rectangular-port heads (such as PN 77485) and a Victor Jr. single-plane intake manifold (PN 2902). Although your ported oval-port heads should provide more usable torque on the street, the low-rise standard Performer dual-plane intake is a poor fit, with an upper rpm limit that doesn’t match the capability of the installed camshaft. Although a single-plane intake is stronger on top, it may not be the best fit for general-duty street use; in your case, I’d lean toward a high-rise dual-plane: either the Edelbrock Performer RPM 2-O (PN 7161) or (preferably, because it runs cooler) an Air-Gap 2-O (PN 7561). For improved daily streetability, you might also consider an entry-level EFI setup, such as FAST’s EZ-EFI self-tuning, self-learning, four-barrel throttle-body conversion. It’s simple to install (unlike a full-on port-EFI system), very driveable, and one doesn’t have to be Daddy Warbucks to afford it.

Not So Easy No. 1 Cylinder ID

We received dozens of responses to Len Cossey’s “foolproof” tip on locating No. 1 cylinder on a V8 engine (Pit Stop, Jan. 2015). As you may recall, Casey stated, “The No. 1 piston on any V-configured engine from a V2 to a V16 or even larger always matches the head that is farthest to the front of the block…That was how my high school shop teacher taught us 50 years ago.” I forgot one of my cardinal rules: Never say “never” and never say “always!” Pontiac V8 guys, I hear you—and should have known better, as I’ve owned two of them myself. The following is just a sampling of our loyal readers’ comments.

Like most other GM V8 engines, the No. 1 cylinder on a traditional Pontiac V8 is the front cylinder on the left-hand side. But uniquely, the forward-most cylinder is No. 3 on the right-hand side. D’oh!

Like most other GM V8 engines, the No. 1 cylinder on a traditional Pontiac V8 is the front cylinder on the left-hand side. But uniquely, the forward-most cylinder is No. 3 on the right-hand side. D’oh!

Len Cossey has been wrong for 50 years. One example: Pontiac V8. Never say “always.”

Jim Schell

Frankfort, KS

Len Cossey’s remark about the location of No. 1 cylinder is incorrect. Worse than that, you agreed with him! No. 1 cylinder on a Pontiac is to the front of the drivers-side bank—which sits behind the passenger-side bank.

“Pontiac Jack” Gifford

Phelps, NY

I work on a lot of Pontiac engines and you wouldn’t believe how many times I’ve run across connecting rods misinstalled because folks assume the front-most hole is No. 1. This includes the good folks at Crower from whom I once bought a wonderful set of Sportsman forged rods for the Pontiac engine, marked as if for a Chevrolet. So once installed, the Crower markings faced the underside of the camshaft and could not be seen from the bottom-end. Not a big deal, I added my own markings and all was well, but it just shows that even the big guys forget Pontiac is different.

James Clark

Metro Detroit, MI

Since the Pontiac V8 was around 50 years ago, [Cossey’s] shop teacher should have known better.

Bob Cella

Via email

I was a tech for more than 40 years and held 27 ASE certifications. I have seen more than one engine type where the front cylinder was not No. 1. The Ford 534-series truck engine is one. I have been retired for some time and know that there are others but don’t recall which makes they are.

Pete Pesci

Via email

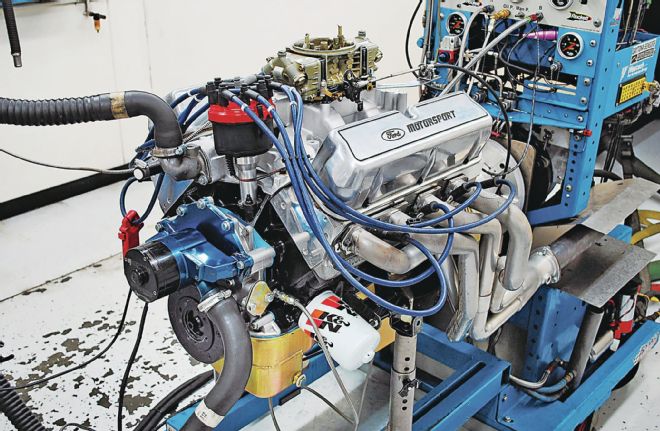

Back in 2011 our sister pub Muscle Mustangs & Fast Fords featured a Richard Holdener–built 408ci Windsor that made 530 hp and 534 lb-ft of torque on pump gas. You can find the article online by Googling “Ford 408 Stroker Mustangs and Fords.”

Back in 2011 our sister pub Muscle Mustangs & Fast Fords featured a Richard Holdener–built 408ci Windsor that made 530 hp and 534 lb-ft of torque on pump gas. You can find the article online by Googling “Ford 408 Stroker Mustangs and Fords.”

Ford 408 Stroker Block Clearancing

I have a 1974 Ford Bronco with its original tired 302. I’m considering picking up a rebuildable 351W and throwing in a 4-inch rotating assembly. Has anyone published exactly where you have to clearance the block? I understand the rotating assembly will still need to be installed to verify actual clearances but would like to see what I’m getting myself into before committing. I’ve considered stroking the 302, but the taller deck 351W [4-inch stroker] makes more sense: 106 added cubic inches [over a stock 302]—there’s no replacement for displacement.

I realize I can buy a short-block or crate motor already machined and assembled, but I prefer to build my own engines (minus the machine work, of course).

Ken Weller

Via email

It’s often not specifically addressed because this is yet another instance where on the small-block Fords, stroker crank clearance issues just aren’t a problem with today’s scienced-out aftermarket kits (unlike typical small-block Chevy strokers). Eagle, Scat, and others offer bolt-in stroker rotating assemblies that clear the cylinders, the main webs, and the oil-pan rails. In fact, not only can you build a 4-inch stroker to yield 408 ci (4.030-inch bore x 4-inch stroke) without problems, engine builder Joe Sherman reports even a Scat 4.25-inch stroker kit clears the block. That yields a 434ci engine (4.030-inch bore x 4-inch stroke)! Points out Sherman, “The 351W’s oil-pan rails are about 2 inches wider than a small-block Chevy.” The 351-Windsor’s tall, 9.500-inch cylinder block deck height provides ample rod-to-cam clearance as well.

A 4.0-inch stroke forged-steel crank, 6.2-inch center-to-center rods, and custom 10:1 forged pistons bolted right into Ford’s production, two-bolt main, 351W block with no reported clearance issues.

A 4.0-inch stroke forged-steel crank, 6.2-inch center-to-center rods, and custom 10:1 forged pistons bolted right into Ford’s production, two-bolt main, 351W block with no reported clearance issues.